Thewarehouse is much more than just a place to store goods. It’s an essential link in your supply chain, because it’s where your goods are managed, organised and prepared for distribution. To ensure that your warehouse perfectly meets your needs, you need to choose the right type.

Find out in this article how to identify the type of warehouse best suited to your business, based on a number of criteria.

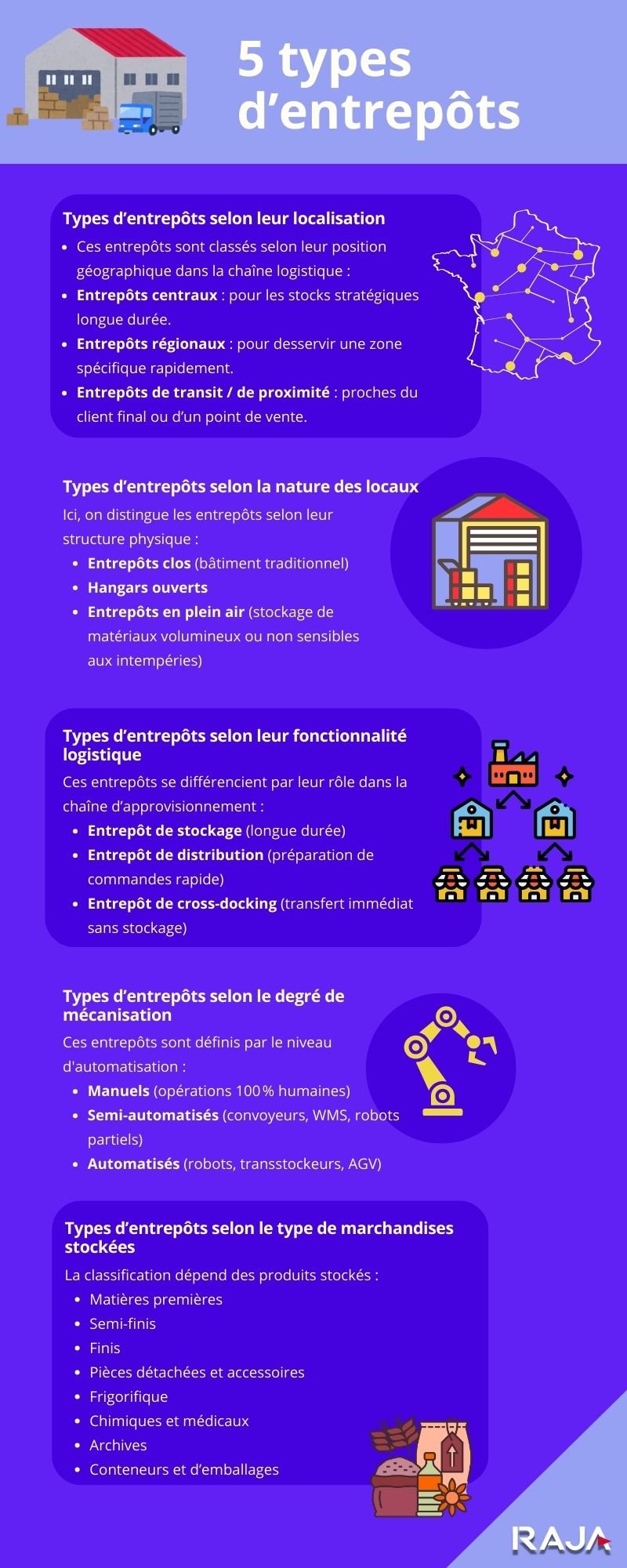

Location: a criterion for determining the type of warehouse to open

You can choose to locate your warehouse in different places, depending on your logistics objectives:

Managing large volumes close to the manufacturing site

Central or production warehouses

These are located close to the manufacturing units and store large quantities of goods. Their main role is to supply regional warehouses.

Reduce delivery times by getting closer to the customer

Regional warehouses

Located close to consumer areas, they ensure rapid distribution to wholesalers or retailers in a specific geographical zone.

Optimise flows between different logistics sites

Transit warehouses

These act as relays between the central and regional warehouses. Goods are stored here temporarily, without any permanent stock being built up.

The type of building: a direct impact on the protection of goods

The choice of building type depends on the nature of the products you need to store:

To protect products that are sensitive to external conditions

Indoor warehouses

These enclosed buildings protect goods from climatic conditions such as temperature variations or humidity.

Storing bulky materials outdoors

Uncovered warehouses (outside)

Delimited and open, these areas are used to store products that do not require special protection against the elements.

The logistics function: a warehouse designed for its purpose

Depending on your activity, you can assign a specific role to your warehouse:

Continuously supply your production lines

Supply or production warehouses

These store the raw materials needed for manufacturing and are located close to industrial sites.

Guaranteeing product availability close to the end customer

Distribution warehouses

Strategically located, they reduce delivery times and maintain a good level of stock.

Speeding up order preparation and dispatch

Order preparation warehouses (picking)

Specialised in picking, these warehouses enable products to be selected and packed quickly for delivery to customers, particularly in e-commerce.

Meeting one-off or seasonal demand

Temporary or seasonal warehouses

These are used to store extra volumes during busy periods such as bank holidays or sales.

Grouping shipments to cut costs

Consolidation warehouses

These consolidate several small consignments into a larger batch, improving productivity and limiting transport costs.

The level of mechanisation: a factor in productivity

Depending on the level of automation you want, you have several options:

Rely on human flexibility

Conventional warehouses

These warehouses have a low level of automation, and operate mainly with manpower and conventional handling tools.

Automate for greater efficiency

The automated or intelligent warehouses

These warehouses are equipped with computerised management systems(WMS) and sometimesartificial intelligence. They optimise stock management and logistics flows while reducing dependence on labour.

Striking a balance between automation and manual operations

Semi-automated warehouses

These combine manual processes with automated tools to improve productivity without incurring excessive costs.

The nature of the goods: an essential criterion for your warehouse

The contents of your warehouse directly influence its layout and equipment:

Supplying production with raw materials

Raw materials warehouses

These are located close to production areas and store materials intended for processing.

Storing products in the course of manufacture

Intermediate or semi-finished product warehouses

These store goods that are in the manufacturing process, but not yet finished.

Managing products ready for sale or shipment

Finished goods warehouses

These store finished items awaiting distribution or marketing.

Organising the parts needed for maintenance

Spare parts and accessories warehouses

These store components used for repairs or replacement.

Maintain a controlled temperature

Cold stores

These guarantee strict temperature control for products requiring specific, controlled thermal conditions, such as perishable foods.

Complying with strict safety standards

Chemical and medical product warehouses

Their management requires specific rules and staff trained in handling sensitive substances.

Keep administrative and legal documents

Archive warehouses

These store all important documents, such as licences, inventories and sales records.

Organising logistical support

Container and packaging warehouses

This is where all the materials, containers and packaging are organised to prepare and protect products during storage or transport.

The right warehouse for efficient logistics

Each type of warehouse meets specific needs. By identifying the characteristics that correspond to your activity, you can optimise your stock management, improve your logistics performance and meet your customers’ expectations more effectively.