The strapping of parcels and pallets is one of the key elements in your order preparation process, as it ensures that your goods are secure during transport.

And at the heart of this process is a key tool: the strapping band.

In this article, you’ll find a short guide to choosing your strapping band, as well as all the machines and accessories you need to strap your parcels and pallets efficiently and ergonomically.

What type of strapping should I choose?

There are several types of strapping . Their choice depends on both the loads you intend to strap and the type of storage you envisage.

| Type of strap | Characteristics | For what type of load? | Use and sealing |

|

|

– Eco-responsible because it is biosourced (made from 95% recyclable paper and 5% vegetable glue) and recyclable – Adds value to your parcels – Conforms to the shape of your parcels – Does not cut, so very safe to handle |

– Suitable for strapping lightweight parcels (tensile strength up to 55 kg) – For short-term storage |

– Can be used manually with plastic buckles or mechanically with a strapping machine – Buckle closure |

|

– Resistant – Much more elastic than the others, it relaxes over time – Less resistant to UV rays than other materials |

– Suitable for strapping parcels, loads and pallets weighing up to 200 kg – For short-term indoor storage |

– Can be used manually or on automatic or semi-automatic machines – Plastic buckle, steel clevis or welded closure |

|

– High breaking strength – Low elongation – Excellent resistance to high temperatures (up to 350°C) – Excellent corrosion resistance |

– Suitable for strapping very heavy loads with low compressibility or with sharp or protruding edges (tensile strength up to 725 kg) – For long-term outdoor storage |

– Manual use – Sealing by capping or caulking |

|

– Eco-responsible (made from 100% recycled PES plastic) – Does not cut, so safe to use – Does not stretch or warp, even when in contact with rigid, heavy products – Insensitive to moisture, UV and temperature variations |

– Suitable for palletising or strapping medium-heavy loads (tensile strength up to 534 kg) – For long-term storage and outdoor use |

– Can be used manually or on an automatic machine – Clevis or welded closure |

|

– Made of woven PES plastic – Highly resistant, does not stretch – Conforms to the shape of loads – Safe to handle – Unaffected by temperature variations, UV rays and humidity |

– Suitable for strapping fragile, heterogeneous products and heavy loads (tensile strength up to 820 kg) – For long-term outdoor storage |

– Manual use – Buckle closure (a knot at the buckle reinforces the closure) |

Note: Are you looking for a more attractive way of tying up your parcels and deterring theft during transport? Consider the eco-friendly alternative of packing cord, made from cotton, linen, hemp or sisal. Find out more about this solution in our article on packing cord.

What are strapping bands used for?

Strapping bands are used to close, secure or group your goods so that they cannot move during transport (in a parcel or on a pallet).

However, not all types of strapping are suitable for all types of goods. You need to make sure that the one you choose allows you to store and transport your products safely and reliably.

| Type of strap | For which uses? |

Paper strapping |

– Strapping to provide additional protection for light packaging against theft – Grouping of products to be stored indoors for short periods |

PP (polypropylene) strapping |

– Bundling of newspapers or magazines – Strapping to provide additional protection for light packaging against theft – Reinforcement of light loads on pallets |

Lacquered steel strapping |

– Strapping of very heavy, pointed and round loads (such as building materials) |

Polyester strapping |

– Palletising medium to heavy loads – Bundling of heavy and specially shaped products (such as iron tubes) |

Textile strapping |

– Strapping goods with fragile surfaces (such as wooden products) – Strapping objects with sharp corners (such as tiles) |

Strapping techniques to adopt

Need to understand how to strap a parcel or pallet? You have two options: do it manually, or get a machine that will mechanise or automate this packaging process. Here’s how.

Manual strapping techniques

Manual strapping should only be used if you have a few dozen parcels to strap per day. Above this rate, you are potentially exposing your operators to the risks of logistics strapping: Musculoskeletal Disorders.

To strap a parcel manually, it all depends on the type of strap you use:

- For PP, paper or textile strapping, use a loop and a tensioner. All you have to do is make two loops in your strapping band and attach them to your loop. You can then tighten the strap by hand or with a tensioner.

- For PP, steel or polyester strapping, use a manual strapping machine (which includes a tensioner and pliers), as well as a crimping clevis. Place the clevis and the strapping band in the pliers, then tighten the band with the tensioner and secure the clevis.

To find out more about these techniques, see our article “Strapping your parcel: best practices for protecting your parcels”.

Techniques for mechanised or automated strapping

Does your warehouse have to manage a high rate of parcel or pallet strapping? To avoid the risk of RSI for your operators, and reduce the workload in the warehouse, include strapping machines in your order preparation processes.

There are several options available:

|

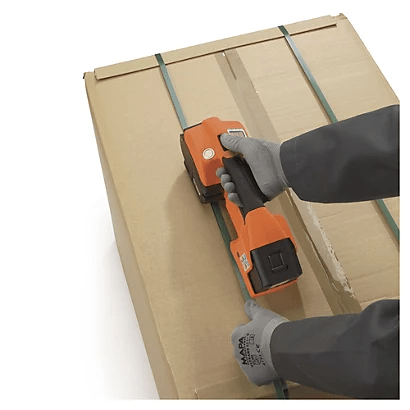

Mobile strapping machines (semi-automatic or automatic) are battery-powered and can be moved anywhere in the warehouse. They help operators to strap 70 to 150 parcels a day. |

|

Semi-automatic parcel strapping machines (or table-top strapping machines) can be used to strap packages of different sizes and shapes, or to group products together easily. They assist operators in strapping, enabling them to maintain an upright posture during the task. |

|

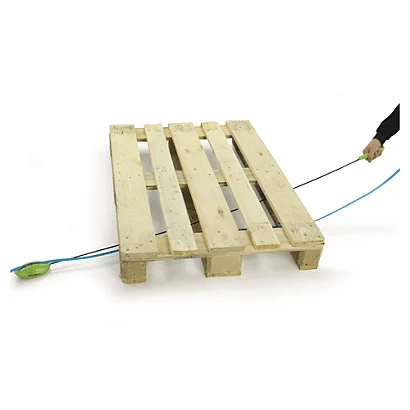

The semi-automatic pallet strapping machine can strap up to 50 low pallets (minimum height: 380 mm) per day. The machine’s arm automatically places the strap under the pallet – all the operator has to do is apply the cover and cut the strapping band. |

|

The automatic strapping machine helps you to strap up to 100 parcels a day. These packages need to be fairly uniform in size. The machine automates the entire strapping operation, from feeding the strap to tensioning it and cutting it. |

To find out more, read our article “How to choose your strapping machine (manual or automatic)”.

4 essential strapping accessories

Don’t leave without thinking about adopting the following four strapping accessories, which will improve the protection of your parcels and the productivity of your operators in the warehouse!

|

Edge protection allow you to protect the edges of your cartons – especially if they contain very fragile products. |

|

The reel trolley includes an unwinder for easy handling of your strap reels. |

|

Self-locking buckles, in steel or plastic, hold your box strapping firmly to the parcel. |

|

The strap holder is a practical accessory that makes it easy to slide your strapping under a pallet, to reduce the physical strain on your back. Ideal for reducing the risk of RSI when palletising by hand! |

Now you’ve got the strapping bands and best practices for strapping parcels and pallets efficiently and ergonomically. Now it’s up to you!