The choice of packaging is crucial for your export activity!

- to protect your goods (I) against impact, weather, theft, etc.

- to optimise the cost of transport (II) by reducing the weight and volume of the package.

Cardboard tops the hit parade!

Cardboard is the most important packaging material, far ahead of plastic, wood and metal. Easily recyclable and reusable, it is a natural material that is very popular with consumers. Double or triple thickness cardboard boxes to protect your goods from the hazards of exporting. Shocks and breakage are all the more frequent and important when shipping abroad (we also talk about double or triple fluted cardboard).

———-

Certifications and special products

please note: ISPM15 certification is required for your raw wood packaging in many countries. Ask your supplier for certification. In addition, some dangerous products require specific packaging + dunnage and UN-approved crates. Seek advice from a packaging expert.

———-

1. The nature of your product

The size, weight, shape and material of your product will guide your choice, as shown in the table below

| Size | Object less than 1.2 m | A standard size cardboard box |

| Object larger than 1.2 m | Contact a packaging expert for customised solutions. | |

| Weight | Up to 50 kg | A double flute box is sufficient |

| from 50 kg to 70 kg | A heavy duty double flute box | |

| from 70 kg to 500 kg | A triple flute box is required | |

| More than 500 kg | A wooden box is required | |

| Shape | Protruding shape(s) | Wrap the goods in protective film |

| Material | Fragile, sensitive to scratches, etc. | Contact a packaging expert to choose the right protection (anti-shock, anti-scratch, PH neutral…) |

———-

How to secure your products

cushioning has two functions

- Prevent product movement.

- Protect against external and internal shocks, between two products.

by creating a protective void or by filling voids (below)

———-

2. Modes and conditions of transport

When you travel, you will not arrive in the same condition depending on whether you choose low cost or business class travel. The same applies to your products.

Find out about the conditions of transport

- the number of load breaks,

- transport conditions (individual packages, pallets, etc.)

- climatic conditions (humidity, cold, heat, etc.)

- average transport time; and possibly storage time

———-

Conditions during transport & storage

moisture is the scourge of maritime transport. There are specific protection solutions: anti-moisture bags or trays, reinforced tar paper, anti-corrosion paper, etc. to be inserted inside your packaging – preferably a crocodile-treated waterproof cardboard box or a wooden box. Respecting the cold chain and extreme temperatures requires technical packaging and control labelling. Contact a expert packaging

———-

3. Closing and securing the package

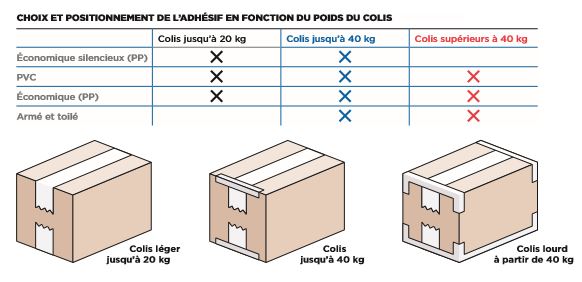

For double or triple flute cardboard boxes intended for export, choose PVC adhesive(58 microns minimum) orreinforced adhesive.

The value of your goods will partly determine the investment against break-in.

Some options often used for export

- a “security” label or adhesive will show a message on the box if an attempt is made to remove it

- awarning label to give precise instructions

- strapping of parcels (if you have a lot of parcels, a strapping machine will be useful to keep up the pace)

- seals; for high value-added products

Volumetric weight is gradually becoming a standard for export pricing.

To optimise the volumetric weight of your packages, there are two rules

- Lighten the weight of the packaging and cushioning( e.g.air cushioning )

- Adapt the packaging to the dimensions of your goods(variable height crate, custom-made packaging, etc.)

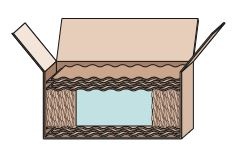

example: this cardboard box with integrated film to gain in volume and lightness

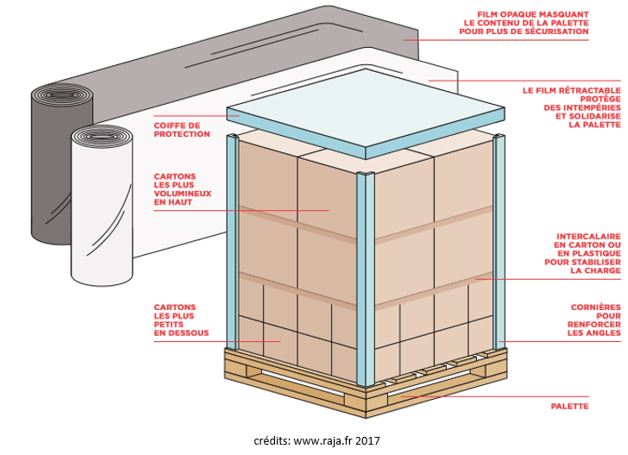

Pallet & palletising: the elements needed to create a homogeneous pallet for export. If you need to make your own pallets in the near future, get help from a logistics packaging specialist.

If you need to make your own pallets in the near future, get help from a logistics packaging specialist.