When it comes to transporting products, the most important thing is always to get them there in good condition. For example, if your products are stacked on a pallet, they can be extra vulnerable, as corners and edges can easily become crushed or otherwise damaged. That’s why edge and corner protectors are available, which can of course also be used for purposes other than palletising. These include protection that is applied directly to the edges and corners of products before they are packaged.

At RAJA we offer a wide range of different types of corner and edge protection, manufactured in different materials and providing protection for a wide variety of purposes. In this post we take a look at the range and for which applications they are best suited.

> What types of edge protection are there?

As we said, there is a wide range of solutions for edge protection, and they come in either foam or cardboard. One of the primary purposes of edge protectors is to protect the edges of crates and boxes stacked on pallets from various impacts and shocks. But they can also be used to protect the product itself before it is placed further into a box. Finally, they can also be used to protect the boxes from the straps that may enclose them on a pallet load.

Edge strips

If we start by taking a closer look at edge strips, then we have protection that is used on the edges of your pallet load. They are made of cardboard with an outer side of kraftliner. As well as being good for protecting the edges from knocks and bumps, they are also good for stabilising the pallet load. If edge strips are used in combination with stretch film/shrink wrap and some strapping, you will have a very stable pallet load that is both held in place and protected from knocks and scratches. The edge strips can also help to protect the boxes from the strapping. At RAJA you can choose from 7 different lengths, 3 different thicknesses and 5 different widths.

U-profiles

A U-profile has a clever tulip design that makes it easy to clamp around the edges of your products, providing good protection. U-profiles are particularly suitable for protecting smooth and delicate surfaces such as worktops, glass and mirrors. U-profiles at RAJA are made of polyethylene foam, which makes the profiles flexible and easy to cut with a hobby knife. The material also makes them high capacity for noise absorption and makes the profiles withstand temperature fluctuations from -40 and +100ºC.

L-profiles

L-profiles can be made of either foam or cardboard. They are ideal for protecting the edges of your products. Corrugated L-profiles are very hard-wearing and will not break when subjected to knocks and blows. This means that they provide optimal protection for the edges of your products. The corrugated board is 100% recyclable, making this type of edge protection an environmentally friendly choice. The L-profiles are delivered assembled, making it easy to apply them to your products. If you want to further secure them to the products, then we would suggest using some strapping tape. Due to the strong layers of corrugated cardboard, you also ensure that the strapping does not cause damage to the product or the box.

Polyethylene foam L-profiles have a closed density that makes them both strong and flexible. They are easy to apply to your products as you can cut them to the desired length yourself using a hobby knife. You can then apply them to your products before placing them in the packaging, giving them optimum protection. The profiles are available with and without adhesive strip, so you can choose whether you want them to be stuck to your product or box.

> What types of corner protection are there?

When shipping or storing your fragile products, it’s not just the edges that need protecting. It’s also the corners of the products that need to be protected from bumps, knocks and scratches. That’s why at RAJA we have a fine selection of different types of corner protection in different formats, so there’s always a solution for your needs.

Cardboard corner protectors

These corner protectors are made of 6-ply corrugated cardboard. This means that they are very strong and shock absorbent. They protect the corners of the products perfectly and without cracking from various impacts. The corner protectors absorb all impacts and shocks and are particularly suitable for protecting products packed in cardboard boxes. The corrugated cardboard is made from 100% recycled cardboard and is therefore also an environmentally friendly solution for corner protection.

Triangular cardboard corners

Perfect corner protection made from double corrugated cardboard. At the joint, the corner protector provides protection on 3-ply corrugated board, providing extra security against impact and shock on the fragile corners of your products. The angle of the triangular corners means they are particularly suitable for protecting some of your flat products. This includes mirrors, table tops, picture frames, doors, etc.

Corner protectors in U-profile

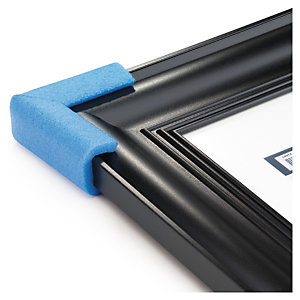

As mentioned earlier, U-profiles have a tulip design that ensures that they clamp tightly around the corners of the product, protecting against knocks, bumps and scratches. Of course, this also means that U-profile corner protectors are fixed without the use of tape. Like triangular corners, they are best suited for the corners of flat products. Like other types of protection made from polyethylene, these corner protectors are also resistant to moisture and temperature fluctuations from -40° C to +100° C.

> Cardboard or foam?

So when should you choose foam and when should you choose cardboard? There are different advantages when it comes to the material used for edge and corner protection. Foam protection is great for uneven surfaces as it is flexible and moulds to the shape of the product. The foam surface means it takes less knocks and blows and grips well around glass surfaces. In addition, foam edge and corner protection is coloured so it can also be used as a marker or warning. It also makes it easy to see that it needs to be removed before using product. Cardboard protectors are much better at protecting products from the pressure of strapping. It is also better at providing stability to packages or pallet loads than foam. Cardboard is more stabilizing on your pallet load than foam protection. It is also often tougher than foam as it is not as flexible.

Want more information?

If you’re looking for more guidance on. choosing edge and corner protection, you are always welcome to contact our packaging specialists on tel. 44 58 77 00 or at info@rajapack.dk.