Palleting step by step – Easy and simple!

Pallets are ideal for carrying larger loads and they allow multiple loads to be tied together into one unit, allowing multiple loads to be transported and stored at once.

But when a pallet needs to be stacked, mistakes can easily occur, which is why we’ve taken a closer look at the palletising process and noted it down step by step. During transport there is always a load. When stacking goods, you should therefore be aware of exactly what loads can occur during transport. With this in mind, you can choose the right packaging for the right pallet type and mode of transport. After all, the requirements for a pallet transported exclusively by truck are not the same as those for a pallet unloaded from a truck into a shipping container or transported by air freight.

A pallet, together with the mode of transport and the goods, therefore constitutes a loading unit. Therefore, you should pay attention to and follow these 5 steps when palletising:

1. Protect and close the estate

The products to be shipped must be optimally packed so that they are well protected during transport. This means that they must be packed in cardboard boxes, for example, with suitable filling material and securely closed with packing tape. Here too, you should take into account the mode of transport: road, rail, sea or air. The choice of packaging should therefore be the result of a consideration of the degree of stress that the mode of transport places on the packaged products.

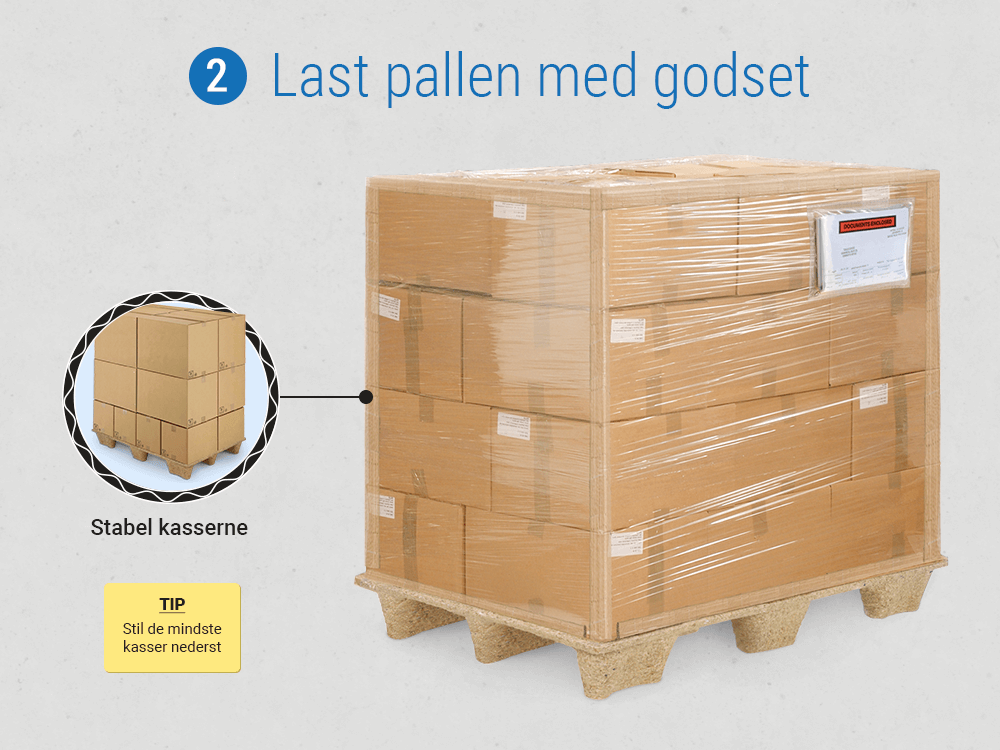

2. Leave the pallet with the goods

In order to create the most optimal loading unit, it is important that the pallet is always loaded in a way that the different packing elements fit the pallet format. If gaps occur, it is essential that these are on the inside or centre of the pallet so that the outer dimensions of the pallet are respected. Any gaps can be filled, for example, with spacers or similar. As far as possible, stacking in “pillars” should be avoided, as this increases the risk of the stack tipping over. This can happen because the stability of the individual cardboard box is lost when all the weight is on the bottom boxes. Therefore, in the case of cardboard boxes of different sizes, we recommend that you place the smallest boxes at the bottom and the larger boxes on top. Stacked cardboard boxes are always preferable because they create a more stable pallet load.

3. Secure the pallet

To increase the stability of the goods on the pallet, you can for example use interleaving paper. This ensures that the individual cardboard boxes stand more firmly and do not slide around. Edge profiles on the sides also reinforce the load and prevent unnecessary strain on the load.

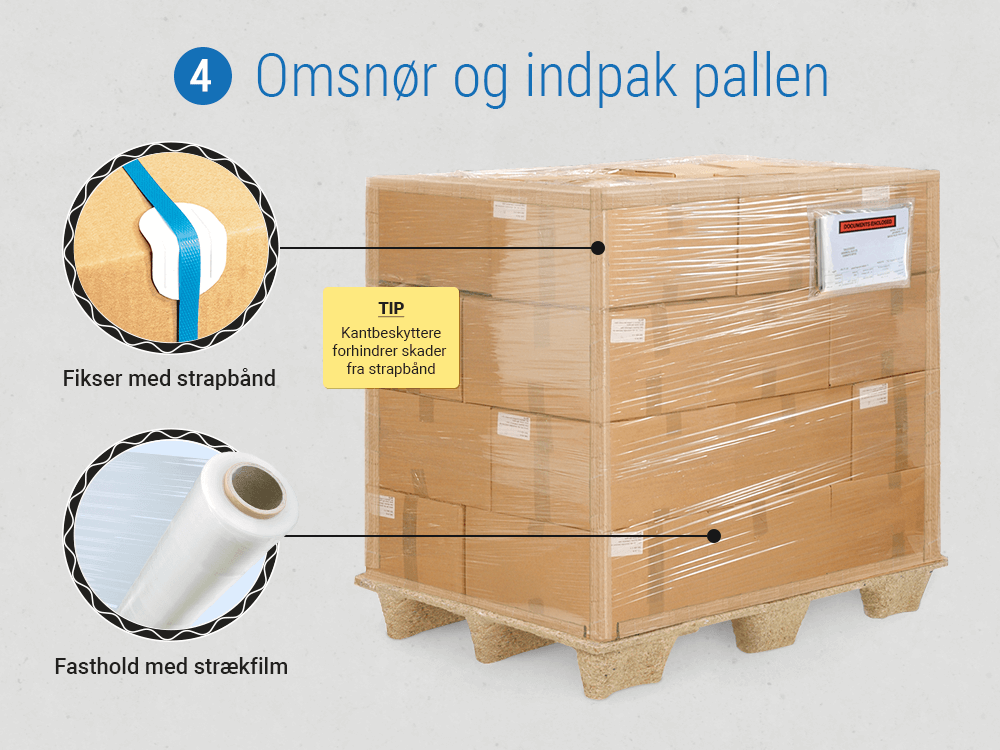

4. Wrap and pack the pallet

To create a unit, the goods and pallet must be held together, and large boxes can be tied directly to the pallet with straps, and to avoid damage during strapping, you can protect the edges of the goods with edge protectors.

Stretch film also protects pallet loads from dust and dirt. However, in the case of manual wrapping, film only provides a barrier against dust and dirt. Only foiling with stretch film machines can provide sufficient security where the film is connected to the pallet. Pallets can also be secured with shrink film, but shrink film requires heat and not all goods can withstand this, so it is not always preferable.

5. Label the pallet

Each pallet must be addressed and accompanied by a consignment note or shipping documents and with consignment note pockets the papers are optimally protected during transport. Furthermore, the contents of the goods should be marked with appropriate warning labels, which are placed on the outside of the pallet load.

If you have followed our 5 steps, your palletising process is now complete: The goods are well secured and the loading unit is ready to be transported and to reach the recipient under the best conditions.

If you have any questions or are curious about our range of palletising products, you can view our entire range at rajapack.com. You are also welcome to contact our packaging specialists Monday to Friday between 8.00 and 16.30 on tel: 44 58 77 00 or via info@rajapack.dk if you would like guidance on choosing the right products for your next palletisation.