Pallet lifters: Boost your warehouse with the right equipment

Goods handling equipment is essential for most businesses that deal in physical products, and for good reason. Equipment enables products and materials to be transported safely from production to the warehouse, on to distribution and finally out to retail. But it’s important to use the right equipment so that the health and safety of your workers isn’t compromised. At the same time, it contributes to efficiency and helps protect products from unnecessary damage.

In this post, we’ll take a closer look at warehouse equipment for product handling, so you can ensure the efficiency and safety of your business.

What types of equipment are available for goods handling?

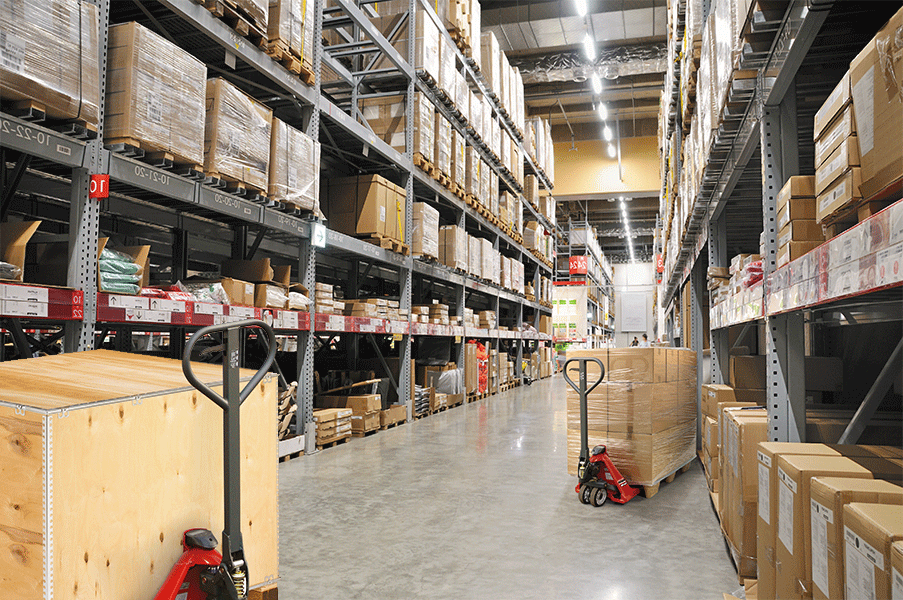

There is a wide range of goods handling equipment, with weight, model and dimensions to match your needs. You can get everything from manual pallet lifters and sack trucks to semi-automatic forklifts and fully self-propelled robots.

If the latter is more than you need then don’t worry! We offer a wide range of sack trucks, transport and shelf trucks and pallet lifters in different sizes to help you maintain an optimal production flow.

What is a sack truck?

Sack trucks are most often used for lighter loads. The trolley works by tilting the weight of the load so that it lies over the sack truck wheels. In this way it can be easily transported. They were originally used by young dockers employed to move heavy sacks of spices around the quayside back in the 18th century.

Sack wagons are usually made from materials such as aluminium, steel tubing or hard plastic, making them lightweight and versatile for a wide range of purposes. But what do you use a sack wagon for? The main purpose of a sack truck is to transport loads from one location to another. This could include heavy stacking of boxes, machinery and or suitcases. They are therefore the obvious choice for baggage handlers at airports.

Sack trucks are incredibly versatile, cheap to buy and easy to use. They allow one warehouse worker to move a load that would otherwise require 2 or 3 men. But while they are easy to use, it is essential for safety that the sack truck is used correctly.

First of all, always check the trolley and its wheels to make sure they are not damaged and to be sure that the weight of the load does not exceed the maximum weight allowed. Then you can place the load on top of the plate (the flat metal piece that follows the floor) so that it is ready to be lifted. Make sure the load is stable before gently pulling the top of the sack truck towards you. You are now ready to push the trolley in front of you.

No special certification is required to operate a sack truck, so it is important that you feel confident in its use and that you know exactly what to do when working with a sack truck. We recommend that you always speak to a supervisor or the manufacturer before using a new sack truck.

What is a pallet lifter?

As the name suggests, a pallet lifter is designed to move pallets. In this way, they are a simplification of the forklift truck, and are most often used to move pallets and their goods around the warehouse. They are available in 2 versions: manual and electric. In this post, we focus on the manual pallet lifters, which is the version most widely used in warehouses and retail.

If you’re looking for a pallet lifter, you might be wondering how much one actually weighs. The answer is that it depends entirely on the individual model. We currently have 6 different pallet lifters and lift trucks in our range, but there are countless models on the market.

The weight of a pallet truck is not necessarily an indicator of how much it can lift, so what is the maximum performance? Again, it depends on the model. For example, our popular dual fork lift weighs 65 kg and has a lifting capacity of up to 2000 kg, while our integrated pallet lift weighs only 58 kg and can lift up to 2200 kg. It is therefore important that you are aware of the pallet lifter’s exact purpose, so that you can work out what weight typically needs to be lifted and moved, as well as where the pallet lifter should be stored when not in use. That way, you can track down which model is right for you.

As with sack trucks, there are no certifications or official training required to use a pallet lift, so it’s important to make sure you know how to use it before you start!

How to use a pallet truck

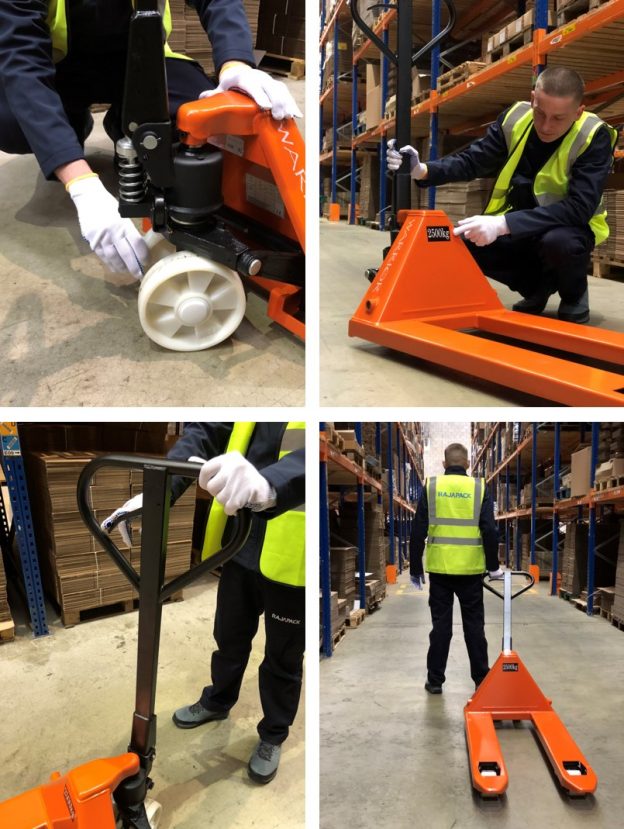

- Before using a pallet truck, check that it (including wheels) is in good condition and not damaged.

- Check the maximum capacity of the pallet lift and make sure that the load you need to move does not exceed the limit.

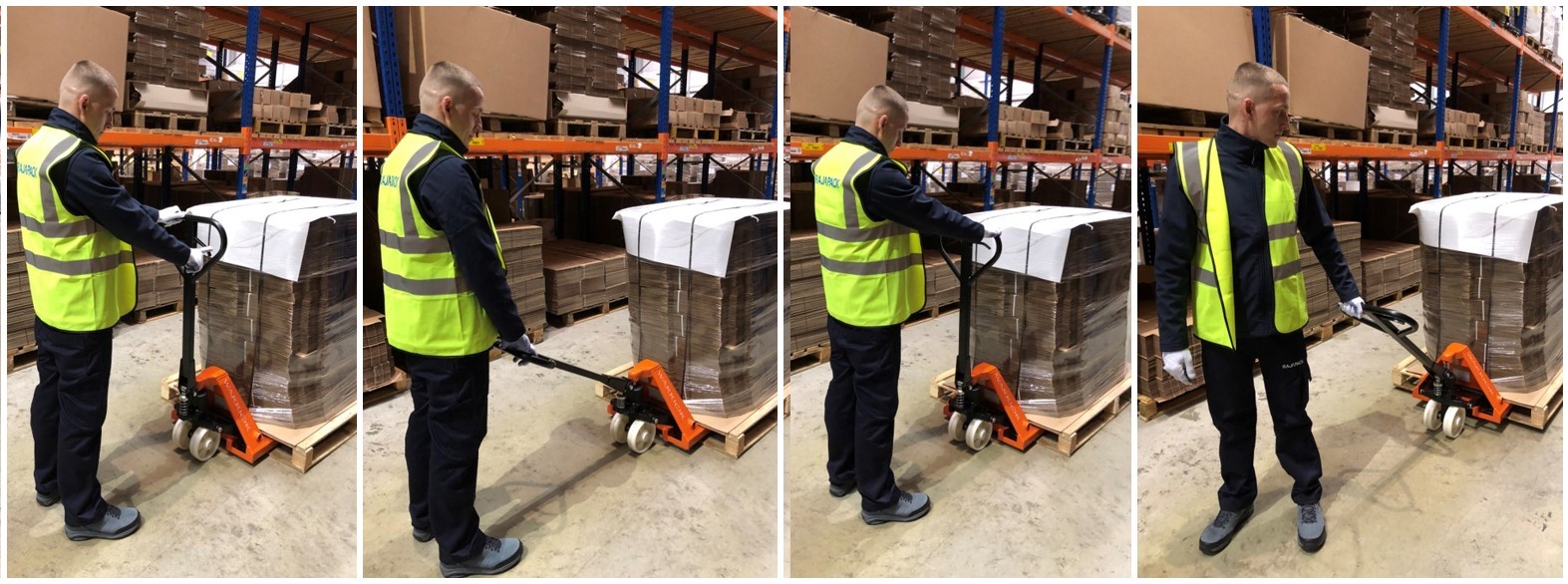

- Locate the release pump (often located near the handle) which lowers the lifting forks all the way to the floor. Pull the pump so the forks drop to the floor and then push the forks under the pallet.

- Once the pallet lifter is in place, pump the handle repeatedly so that the forks lift off the floor again.

- When the forks and the goods are at a suitable height, the pallet lifter is ready to be moved.

And don’t forget that you should always talk to your supervisor or the manufacturer before using the pallet lift!

How does a pallet lift work?

Manual pallet lifters can lift and move heavy loads thanks to a hydraulic lifting system. When the release pump is pulled, hydraulic fluid is released, which lowers the forks. When the handle is then pumped repeatedly, the pressure in the hydraulic fluid increases, lifting both the forks and the load.

How should you move a pallet truck?

Manual pallet lifters can be pushed or pulled, but because most people are able to push more weight than they can pull, pushing is safer. To find out the safest way to use a pallet lift, always talk to your supervisor, the manufacturer or, if you prefer, read our short guide above.

At Rajapack we have a wide range of not only pallet lifts and sack trucks but also transport trolleys, shelf trolleys and cages, which are also extremely useful for everyday work in the warehouse.

If you would like to know more about our range of goods handling equipment or would like guidance in choosing the right model for your business, our experts are ready to help Monday to Friday 8.00-16.30 on tel. 44 58 77 00 and via info@rajapack.dk.