All indications are that the coming months could well be a bit chaotic, as commodity shortages lurk in the various supply chains and threaten to jeopardise both Christmas and Black Friday.

Go after your voids and minimise the air in your shipments, there is money to be saved here as freight companies often price each shipment by volumetric weight – make full use of the capacity of each carrier especially at this time.

It’s important that you have your own ‘supply chain’ and the whole back end under control – if everything is packed and ready, both in your communications, your packaging, your parcel flow and in your warehouse – then there is more surplus to deal with any challenges elsewhere.

So we’ve put together 4 quick tips to help streamline and prepare your packaging for the busy season – enjoy!

One parameter that can make a difference to both you and your customers is if returns run smoothly. Customers like that they don’t have to think and do too much.

A: Inform and make your return process transparent

Make it clear how the returns process will work.

For example, you can. briefly and precisely describe the return process at the ‘check-out’ when the customer places their order, or on the order confirmation, you can also include a flyer in the package with all the steps described (I’ve seen QR codes before that order a return), you can also include a return label (paid or not), it helps the customer a lot along the way – but no matter which method you use, customers like the information dumped right in their heads so they don’t have to do too much in their busy day.

Small steps like a transparent and easy returns policy make for happy customers who return because they didn’t have to lift a finger.

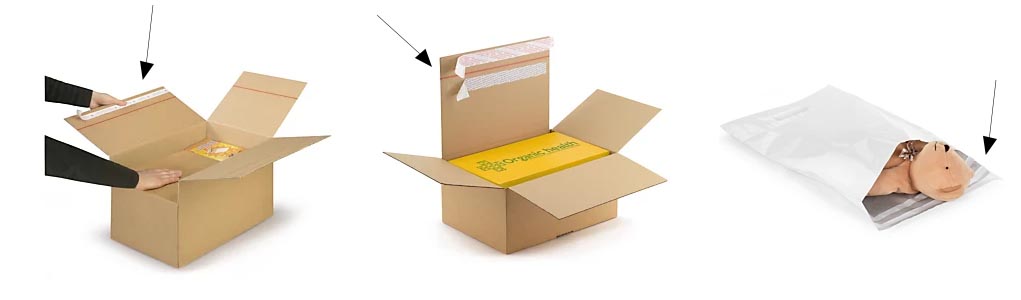

B: Offer packaging with an integrated returns solution

As an add-on to the above, you can offer packaging in which customers can send back their items. This is a WIN-WIN for the environment, the customer and ultimately for you, as you control the quality of the packaging in which goods are returned.

If you have a particularly expensive item out and about – then you can create a process where you send a return packaging, but only if you wish to return – again it is just important to inform the customer of your process, then the options are many – the return policy needs to be adapted to your products and likewise the packaging with the return solution also needs to fit the product.

If you are sending clothes or other garments, the shipping bag, with or without a handle is a particularly good choice. If you need a box, you can find one here with a return closure.

C: Create a system all along the way:

Transparency in returns is not only important for the customer, but also for the employees back at the warehouse and especially when Black Friday hits. In the warehouse, everything needs to play and the flow needs to be smooth.

Do yourself a favour and make a detailed plan for receiving returned goods. Get the goods back on sale as quickly as possible – have a clear plan for each step: receiving, registering, crediting, etc. etc. This will save you time and storage space. At this time, it is really important to get the goods back on sale as soon as possible – taking into account the shortage of raw materials and bottlenecks, as mentioned before.

Once the item is ordered and you need to pack, it is important to have packaging that is not cumbersome and difficult to assemble. It’s also important that you don’t have to search for the right box between 50 different sizes.

Storage space, your packaging budget and your packing flow need to be optimised and ready for the busy season. If you need expert advice, our packaging specialists will be happy to visit and help with the optimisation, just call them on 44 58 77 00.

We give you the quick answer to optimising your parcel flow here:

Choose boxes with automatic bottom:

Boxes that are assembled by lightly pressing the sides are assembled 2.5 times faster than a standard folding box. Which saves you time when the boxes need to be assembled and filled. Below the assembly is shown in comparison to the an ordinary folding box:

Select variable boxes:

If you have many different products in different sizes, it is worth thinking about a box that can be adapted to several different products. A variable box can be cut to size, saving space in your warehouse, possibly in your packaging budget, and also saving you time searching for one box among many.

Choose adhesive closure:

The two options above are available with adhesive closure. That means you save the tape and the time you spend applying it. Moreover, the recipient does not have to think about separating the plastic tape from the cardboard packaging before throwing it away for recycling. Optimise, optimise, optimise – but only optimise if it makes sense for you and your business.

Automate with packaging and parcel filling systems:

When there are a lot of packages to go, there’s a lot of package filling to do. Here, a machine can be VERY effective to have on your packing table or at your packing line.

In our complete catalogue with the theme Machine and Packaging Systems, you can see the entire range in one place:

If you handle more than 10 parcels per day, there is a good chance that a packaging machine can save your company both time and money. Many machines can actually be rented, so you don’t necessarily have to worry about paying a large sum of money for a machine all at once. Contact our specialists and have them analyse your needs for free – 44 58 77 00.

When you acquire a machine, we are with you every step of the way, from idea to installation, training, maintenance and servicing of machines with a service agreement.

Below you can see a demonstration of our Padpak Guardian machine, a machine that can produce up to 72 metres of paper fill per minute and can be placed both at a packing line and at a packing table.

This means it’s ideal for a company that sends out a lot of parcels a day. The machine is best suited for companies that produce 1000 to 1500 parcels per day.

Explore our catalogue – you’ll find machines for every need.

When the customer receives your parcel, it is often the last and best impression the customer will have of you and your brand. This is where all the endorphins are released and the happiness of receiving your ordered goods happens. Therefore, this is also where you can impress and give the customer an image of ‘you’ve got this’. Make the experience unique with, for example, a logo or customised packaging. As well as adding value to the customer, your packaging will also be a promotional pillar when it is shipped from A-B.

When it comes to custom packaging, the possibilities are endless. You can personalise with print, but also with clever design, shapes and features. Almost anything can be done, but remember to think about whether the investment in custom packaging is worthwhile.

An example might be:

…the print run needs to be large enough so that the unit price doesn’t run off – because custom packaging can be expensive. Another scenario might be that you have such a special product that it requires custom packaging for protection reasons, here it’s a different equation you have to make… but all this our packaging specialists will be able to help you with:

They can be contacted here:

44 58 77 00 | info@rajapack.dk

The easy and affordable solution is to have your tape printed, transforming any kind of package into a personal and integral part of your communication.

Below you can see an example of a tape we made for Copenhagen Home Design, a white tape with black print, in other words a ‘Negative Print’. If you would like to embark on a ‘Tape with Print’ please feel free to read this post, which will give you the necessary background knowledge when designing your ‘Tape with Print’.

The last tip for this time goes hand in hand with the previous 3 tips. If your warehouse is cluttered and disorganised, then none of the previous advice will be fully utilised. Make sure that all stations are running smoothly and everything is continuously replenished, so that nothing is missing when packages need to be packed quickly.

Our range includes shelving, picking boxes, packing tables, trolleys, lifting tables, pallet lifters, ladders, magnetic labels, etc. All of which come in handy when you want the warehouse to run smoothly.

Picking:

For small warehouses, make sure all items are easy to find, organised in a system and constantly replenished. This can be done with clear shelves, picking boxes and magnetic labels for labelling.

Elephant feet, ladders, pallet lifts and transport tables will be useful for easy handling of goods as they move from one place to another.

Packing station:

At the packing station, whether it is a packing line or a small packing table, the flow should run itself. At small packing stations, it’s a good idea to keep the relevant boxes close at hand and constantly replenished, so that nothing is ever missing – not tape, follower pockets or work knives. It’s also smart to have an electronic label printer that can be linked to your systems.

On the big packing lines, it’s important to automate as much as possible, for example with pack fillers, strapping machines, stretch wrappers, etc .

Should you need further guidance on optimising your warehouse and logistics before the packing race starts, contact our packaging specialists, they are ready to help with the right solutions for you and your business.

Our packaging specialists can be contacted via: 44 77 58 00 | info@rajapack.dk | Live chat.

… and now remember to think about your voids, minimise your volumetric weight and save on your freight costs – read this blog post to find out how:

Follow us on social media where we provide useful tips for your packaging and sign up to our newsletter where you will receive news and exclusive promotions straight to your inbox:

- Subscribe to our newsletter.

- Follow RAJA Denmark on social media: LinkedIn, Facebook.

- Get our product catalogue at home or read it online where you can add products to your basket directly from your reference book.