The human hand is the real “worker”, it is our most important tool for almost all activities. And yet it is an anatomical marvel: it consists of 27 bones, a quarter of the bones in the entire human body. Then there are 33 muscles, three nerves and four neurovascular bundles for each finger, which are responsible for their activity. Among other things, each palm has 17,000 emotional corpuscles.

It is incredible how often we use our hands and fingers and how even a small injury can limit our daily lives. We all know it, just a small cut on a piece of paper or a splinter in the palm of the hand while gardening. That’s why protective gloves are the norm in many occupations.

All the prescribed requirements for protective gloves are laid down in EN 420.

What must protective gloves protect against?

Which external influences are protective gloves supposed to protect against? This question is crucial if we want to find the right gloves. This is the answer we get most often from our customers:

– Against mechanical hazards such as abrasion or cutting ( EN 388 ). Some anti-cut gloves, for example, allow precise handling of sharp objects in dry environments.

– Against thermal hazards such as extreme heat and fire ( EN 407 ).

– Against chemical hazards such as contact with chemicals and micro-organisms ( EN 374 ). For these cases, disposable latex gloves are suitable.

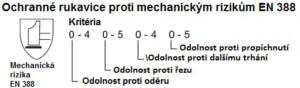

Protective gloves against mechanical hazards

Protective gloves bearing this marking have been tested in accordance with EN 388 and are therefore suitable for protection against mechanical influences. However, there are many differences, which are documented and categorised during rigorous testing. In doing so, the following properties are tested:

RESISTANCE SCALE:

Abrasion resistance: 0 = low, up to 4 = very high

Cut resistance: 0 = low, up to 5 = very high

Resistance to further tearing: 0 = low, up to 4 = very high

(means: if the material is already damaged, for example by a cut, how quickly the material will tear further at that point)

Puncture resistance: 0 = low, up to 4 = very high

The four-digit number below the symbol explains in which requirements the gloves have the best protective properties. Thus, for example, if the numbers 3 2 2 1 are given, the gloves have a relatively high resistance to abrasion, an average resistance to cutting and further tearing and a relatively low resistance to puncture. It follows: the more demanding the conditions against which the glove must protect the wearer, the “stronger” the material must be. If a precise grip and feel is required when the gloves are put on, the material used is “soft” and this usually reduces the resistance to cuts and punctures.

If an X is found instead of a numerical value for each pictogram, this means that the gloves have not been tested for the relevant risk.

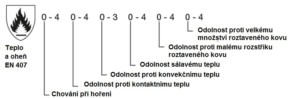

Protective gloves against thermal hazards

When hands are exposed to high heat at work, protective gloves must meet the requirements and test methods of EN 407. Similar to the test methods for protective gloves against mechanical influences, the protective properties against thermal hazards are also tested. The protective requirements for thermal performance are indicated next to the pictogram according to the area of use in the range 0 to 4 ( or 0 to 3):

Heat and fire

EN 407

RESISTANCE SCALE:

Burning behaviour (0 low to 4 high)

Resistance to contact heat (0 low to 4 high)

Convective heat resistance (0 low to 3 high)

Radiant heat resistance (0 low to 4 high)

Resistance to small spatter of molten metal (0 low to 4 high)

Resistance to large amounts of molten metal (0 low to 4 high)

If you find an X instead of a number in the marking, it means that the gloves against heat and fire have not (yet) been tested for the relevant risk.