There are still those who can “fold” a large number of differently shaped cartons into a perfectly unified load. In their private life, they probably spend hours at the dishwasher to cleverly fold and place even the last cup.

A homogeneous pallet load

If the packaged goods are uniform in size and ideally the outer dimensions match the dimensions of the Euro pallet, the goods can be easily palletised as follows:

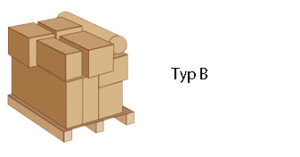

Heterogeneous, heterogeneous pallet load

In practice, however, “perfect” loads are rarely found:

Here, a load of different shapes has been loaded onto a pallet. However, to achieve the best possible stability, some basic rules must be observed.

As with the construction of a stable tower from blocks, the need to avoid columnar stacking applies here. The load is then better able to withstand external forces such as truck braking.

In addition, this effect is greatly enhanced by the use of anti-slip pads.

Professional load securing method

Professional fixation is crucial for the stability of the load. Regardless of whether the wrapping is manual or by machine, the following procedure applies, with semi-automatic and automatic pallet wrappers already controlling this procedure.

1. unwind the foil about 1 m and tie it firmly behind the pallet leg (no need for machine wrapping)

2. wrap the bottom of the pallet 5 to 12 times, depending on the weight of the load, to secure the goods firmly to the pallet

3. Then spiral wrap (with a recommended overlap of 60%) with a wide wrap upwards

4. Wrap the top of the pallet about 3 times and continue spiralling downwards again

5. Tear off the foil just before the last wrapped wall and smooth it with the palm of the hand.

Professional wrapping – blown and cast film

Depending on the type of load (Type A, B or C) there are suitable and less suitable types of wrapping films. In principle, however, additional strapping will substantially ensure increased stability. The table below explains when and which type of film is recommended. Blown and cast films differ in their manufacturing process.

Information on which type of film is used can be found on our website for each product and also in the printed catalogue.

| Foil type | Thickness | Weight | Type of pallet load |

| Cast film | ≤ 17 µ | ≤ 600 kg | A |

| Cast film | 17≤ 20 µ | 600 – 800 kg | A, B |

| Cast foil | 20 ≤ 25 µ | ≥ 800 kg | A, B, C |

| Blown film | ≤ 17 µ | ≤ 600 kg | A |

| Blown film | 17 ≤ 20 µ | 600 – 800 kg | A, B |

| Blown film | 20 ≤ 25 µ | ≥ 800 kg | A, B, C |