It is not only valuable porcelain that needs to be well protected during transport. In the case of metal products, proper protection against corrosion and oxidation also determines whether the component loses its service life.Both problematic situations occur in the presence of moisture or oxygen. It is therefore necessary to prevent metal components from coming into contact with both moisture and oxygenation. These functions are ensured by special papers which, thanks to their insulating layers, protect the metal surface of your products against harmful influences from the outside.

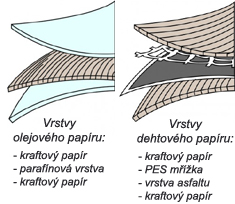

For example oil paper can be used in the engineering or automotive industry for shipping or storing greasy parts such as bearings or sheet metal. It consists of thick kraft paper and is coated with a paraffin layer. This corrosion protection becomes absolutely waterproof and protects the packaged item against the effects of moisture. Although the oil paper is so strong and stable that even sharp and heavy objects can be wrapped in it, it is easy to fold and adjust to the shape of your goods.

Want to protect larger metal parts in your crates or line cardboard or wooden containers with an insulating layer during export abroad? Then rely on terry or tar paper. Tar paper consists of several layers to ensure perfect corrosion protection. Two layers of kraft paper wrap a polyester grid and one bitumen layer. Bitumen is a mixture of various organic substances in the form of tar or asphalt that seals well and is waterproof. Tar paper can thus be used as a vapour barrier or as insulation. Due to its extreme strength, it is recommended for very heavy objects or goods with sharp edges. Metal parts can also be stored or distributed in this type of paper.

So don’t give metal deterioration a chance and take advantage of the simple but effective corrosion protection – whether for long-term storage or for export overseas!