In our last article we revealed all the secrets of paper cushioning, this time we’re going to take a look at its sister product: plastic air cushioning. You don’t need to be an expert in the field to know that good cushioning and protection is important for your packages, but you may be unsure of what to choose. With this article, we’ll help you find the plastic air cushioning that’s right for you.

su_spacer]

1. Plastic air cushioning, your solution?

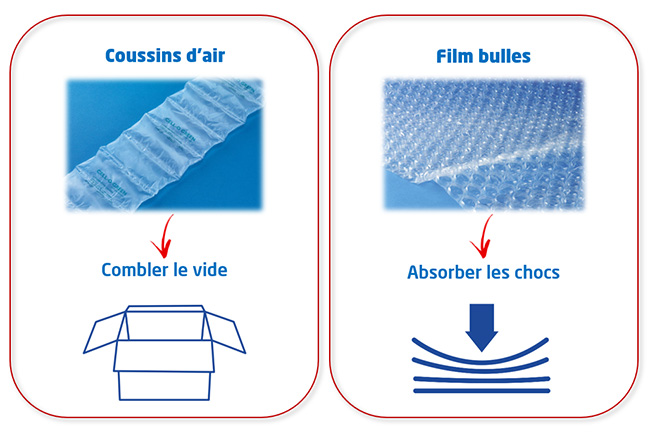

Whether it’s in theform of cushions or bubbles… plastic air cushioning

is a

must-have that’s hard to resist thanks to its many benefits. You can be sure that your shipments will arrive in good condition to their recipient. Air cushioning is an ideal solution for

► Filling the gap (with air cushions) in a presentable way in your parcels and thus prevent your products from moving in all directions► Absorbing shocks(with bubble wrap) when shipping delicate and/or fragile products.

2. The strengths of plastic air cushioning

![]() Air cushioning is very light: you will save on your shipping costs.

Air cushioning is very light: you will save on your shipping costs.

![]() It is easy to handle, so less effort for your packers and more productivity.

It is easy to handle, so less effort for your packers and more productivity.

![]() It does not generate dust. Your workplace and the inside of your parcels will always be clean.

It does not generate dust. Your workplace and the inside of your parcels will always be clean.

![]() It is very protective: air cushioning has excellent shock absorption and is waterproof. It is suitable for both light and heavy products, as well as more specific products thanks to the different variants: antistatic bubble film or aluminium-coated cushioning film for items that are sensitive to electricity or to thermal shocks.

It is very protective: air cushioning has excellent shock absorption and is waterproof. It is suitable for both light and heavy products, as well as more specific products thanks to the different variants: antistatic bubble film or aluminium-coated cushioning film for items that are sensitive to electricity or to thermal shocks.

![]() It is attractive: air cushioning allows full visibility of the product it protects, so that it is easily identifiable by the customer and by the store

It is attractive: air cushioning allows full visibility of the product it protects, so that it is easily identifiable by the customer and by the store

su_spacer]

3. Even more advantages with a dunnage machine

► Gain de temps : posséder un système de calage assure un gain de temps. Certains systèmes produisent jusqu’à 30 m de calage par minute. Rapide n’est-ce pas ? De plus, vous aurez la possibilité de fabriquer votre film bulles ou vos coussins d’air quand vous le souhaitez, sans dépendre d’un fournisseur. Vous pourrez même vous y prendre à l’avance en utilisant un enrouleur automatique.

► Gain d’espace : si vous optez pour un système de calage air, vous gagnerez énormément d’espace dans votre lieu de stockage. En effet, certains rouleaux de film (d’à peine 20 cm de largeur) équivalent à 12,9 m³ de calage. Il suffirait de 7 petits rouleaux pour remplir tout un camion. Imaginez-vous l’espace gagné ?!

De par ces 2 avantages, il est évident que vous gagnez également de l’argent avec un système de calage. Ce n’est pas un secret pour personne, fabriquer son matériel soi-même permet de faire de

De par ces 2 avantages, il est évident que vous gagnez également de l’argent avec un système de calage. Ce n’est pas un secret pour personne, fabriquer son matériel soi-même permet de faire de

4. Which air cushioning machine to choose?

Which system best suits your needs? Below is a brief overview of the RAJA cushioning systems:

Cushioning machine |

Output |

Features |

| Rapid Fill™ portable inflator |

– Up to 100 packages/day | – For fill the voidproducing air cushions. |

| AirFirst |

– Up to 100 packages/day | – For fill the voidproduct of air cushions. |

| Fill Air® Rocket | – 500 to 2000 packages/day | – For fill the voidproduct of air cushions. |

| New Air® | – 500 to 1500 packages/day | – For absorb shocks– Produces bubble wrap. |

| RAJA | – 300 to 1500 packages/day | – For fill the gap or absorb shocksproduces air cushions or bubble wrap. |

Rapid Fill™ portable inflator► fills the gap

Rapid Fill™ portable inflator► fills the gap

This inflator is very handy for filling gaps in your packages, especially if you don’t need cushioning material on a regular basis. It is very compact and easily transportable, plus it has a cannula for easy filling of air cushions

.

AirFirst® machine► fills the void

AirFirst® machine► fills the void

The AirFirst® is the most compact machine in our range and is a good alternative to the above inflator. It automatically makes air cushions that allow you to easily fill voids in a case. You can also use the inflated film as a buffer to separate products from each other. It is ideal as an entry-level model for small consumers.

Fill Air® machine®rocket► fills the gap

Fill Air® machine®rocket► fills the gap

This system is effective if you are packing between 500 and 2000 parcels/day. It produces up to 30m of cushioning per minute. It is very compact and can be placed on a table or packing station. It is also versatile with 6 cushion sizes and 2 film widths available.

New Air® machine► shock absorbing

New Air® machine► shock absorbing

This machine will allow you to fill up to 500 to 1500 parcels/day. You can choose between transparent film or translucent black film (= 15% recycled). Your products will be optimally protected throughout the shipping cycle. Moreover, if you equip yourself with an automatic rewinder, you will be able to make your films in advance.

RAJA® machine► filling the gap or absorbing shocks

RAJA® machine► filling the gap or absorbing shocks

We conclude our comparison with the most versatile of all machines. The RAJA machine can produce air cushion or bubble film and can process up to 1500 packages per day. For the RAJA machine, many different types of film have been developed. Opt for film made from 50% recycled material or use industrially compostable potato starch film.