How do you know if your warehouse is well organised? To do this, you need to ask yourself the following 2 questions: “Is

the

flow of goods optimal?” In other words, does everything get to where it should go quickly, without wasting time. And: “Are your goods stored in an efficient racking system?” In other words, are your racks suitable for your products. Let’s start by looking at the different methods of storage. As you probably know: smart storage does wonders for your workflow.

1. The two basic methods of storing goods

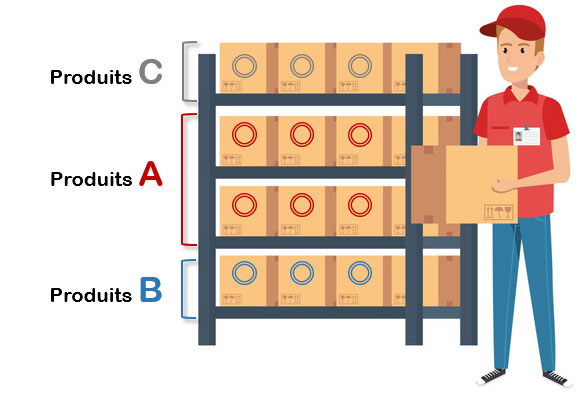

► Method 1: ABC

Acommon way of thinking about stocking goods on shelves is the ABC method.This system takes into account the stock turnover rate.The higher the turnover rate (and therefore the more a product is sold), the easier it should be for your storekeeper to access.It’s best to place these products at eye level, well in the middle of your rack.You can use this formula to calculate the turnover rate of your goods: Purchase cost of goods sold / average stock (at purchase cost)

.Then, use the results to rank your products-

Category Acorresponds to approximately 20% of your SKUs, and an average of 80% of all rotations, so these popular products must be at man-height for your pickers.

-

Category B includes 30% of your SKUs (and ± 15% of your rotations). These products are removed from stock less often and can therefore be stored at the bottom of the shelf.

-

Category Ccorresponds to 50% of your references and only 5% of your rotations. Products in this category are less popular and should therefore be placed on the top shelves.

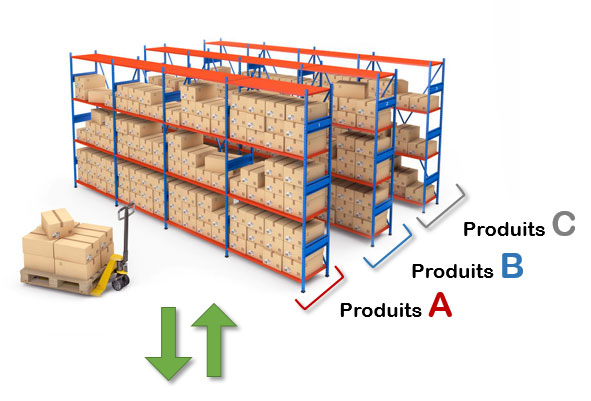

This same method can also be applied to your entire warehouse.Category A products should be stored as close to your packing stations as possible.The further away you are from the packing stations, the less popular and less sold the products.This is followed by B products and at the very bottom by C products.

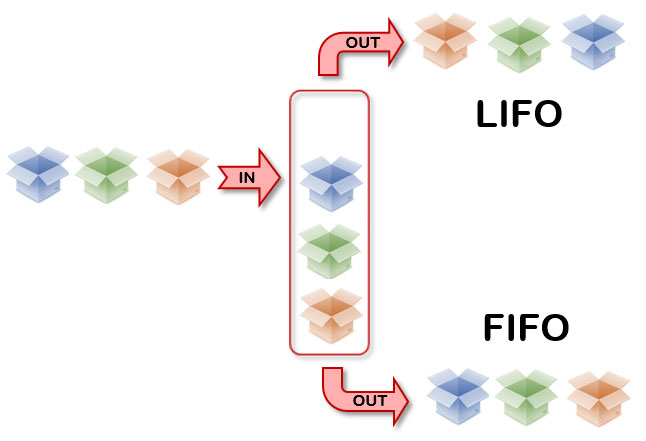

► Method 2: LIFO or FIFO

Ces deux méthodes peuvent être opposées l’une à l’autre, mais ont le même raisonnement de base. La méthode LIFO signifie Last In – First Out. Selon ce type de classification, les produits qui ont été placés en dernier lieu dans votre entrepôt seront les premiers à en ressortir. Comparez-le avec une pile de plateaux sur laquelle le dernier plateau est également le premier qui en repartira.

Dans le même ordre d’idées, la méthode FIFO : First in – First out. C’est le principe inverse. Les produits qui ont été stockés en premier, sortent aussi en premier. Ceci est idéal si, par exemple, vous travaillez avec des produits qui ont une date de péremption. Vous voudrez alors bien évidemment qu’ils sortent de votre entrepôt dès que possible.

- In the case of manual picking, it is sufficient to leave a few centimetres of free space above and between your stored goods/crates.

- When picking with machines, it is recommended to maintain at least 10 centimetres of free space (at the top and on both sides)

► Conclusion: which storage method is best for you?

La méthode la plus couramment utilisée est la méthode ABC. C’est la technique de stockage la plus efficace pour réduire au minimum les mouvements et les efforts de vos magasiniers. Toutefois, si vous vendez des produits avec une date de péremption, combinez la méthode ABC avec le modèle FIFO. Les produits les plus anciens seront ceux remis sur le marché en premier.

Et qu’est-ce qui se passe chez RAJA ? Nous partons d’une méthode ABC : les 1 000 articles les plus populaires sont stockés les plus proches des tables d’emballage. Plus vous vous éloignez des tables d’emballage, plus le taux de rotation de ces produits sera faible. Dans le même contexte, nous appliquons également la méthode FIFO : les produits stockés depuis plus de 100 jours sont les premiers à sortir de l’entrepôt. Comme vous pouvez le constater, les combinaisons des différentes méthodes de stockage sont parfaitement possibles !

[2. Choose the right shelving for the best storage

With a few well thought out letters of the alphabet, we have been able to determine the best order in which goods should be stored. In this second part, we look at 5 storage systems, all of which are suitable for your products or needs. Which type of racking is right for you? The most common racking for the average warehouse can be found in the guide below (PDF download)

► Option 1: Shelving

This racking is for (small) products with a high turnover rate.For those using the FIFO method, this can be very useful.It is best to store your products with the highest turnover rate at head height.The rest of your products are then placed on top or underneath.When using a shelf, it is advisable to store the heaviest products at the bottom and the lightest ones at the top.Lastly, limit the height of your racking to around 2m.This will be easier and more ergonomic for your warehouse workers.

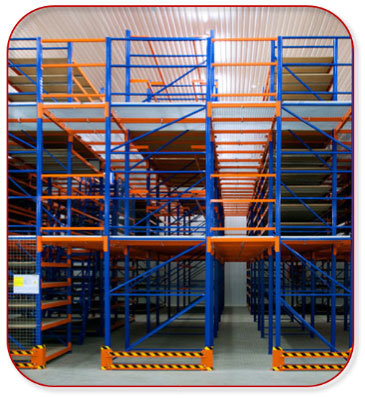

► Option 2: mezzanine storage

This storage equipment is based on the same principle as the previous one, except that here your warehouse is divided into two floors. On each mezzanine floor, an area can be set up for the placement of shelving. Thanks to a better use of the available storage space at height, there is more space between the shelves. This is necessary to ensure a good circulation of pallet trucks, for example. Don’t forget to properly delimit these types of storage areas

with

floor markings and protective barriers.

► Option 3: modular shelving

This racking is particularly suitable for products that are difficult to transport on pallets, such as pipes, tubes, carpets, etc. This racking is also useful for storing seasonal products, whose storage capacity can therefore fluctuate considerably throughout the year. Depending on the model, you can stack up to 3 such racks on top of each other. There are variants that can be usedindoors oroutdoors (thanks to their galvanised steel finish).

► Option 4: pallet racking

For a B2B company, this is the most recommended storage method.It is best suited to storing large quantities of goods, often stacked on pallets.It is best to use pallet racking for this storage.The pallets rest on strong beams that can support a weight of up to 3,000kg.The best thing to do is to attach metal barriers around your pallet racking.This way, your racks and goods are optimally protected against impact.

► Option 5: narrow-aisle storage

If you have a warehouse where you can work at height without too many obstacles, opt for narrow-aisle storage. With this type of storage unit, the distance between the racks is just wide enough for a special picking machine. This picking machine has a very high lifting height. This type of storage is particularly useful when you want to store a large quantity of small products in a limited area. This way, you make maximum use of the available height.

Watch the video below and see how RAJA applies this principle in its own warehouse: