PLA stands for polylactic acid and is a bioplastic that is increasingly used for the manufacture of packaging and tableware(cutlery, cups, tumblers, etc.) It is popularised due to its image as a plant-based alternative to conventional plastic (made from petroleum). Below, we will outline the benefits of this raw material and look at its most common applications.

1. What is PLA?

Comme indiqué précédemment, PLA signifie acide polylactique, ou PolyLactic Acid en anglais. En chimie, on l’appelle “thermoplastique”. Il s’agit d’un plastique qui se ramollit une fois chauffé. La grande différence par rapport aux plastiques traditionnels est la matière première. Le PLA n’est pas fabriqué à partir de pétrole brut, mais bien à partir d’une source végétale renouvelable. La base est constituée d’acide lactique obtenu à partir de cultures agricoles comme le maïs.

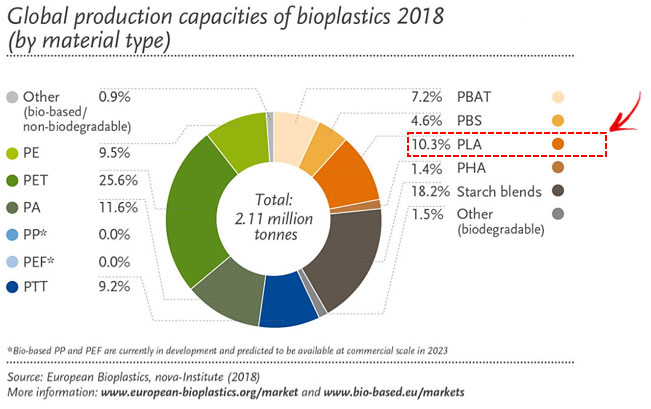

Le diagramme ci-dessous nous montre que le PLA représente un peu plus de 10 % des bioplastiques produits en 2018. D’ici 2023, ce chiffre pourrait atteindre 16,2 % 1. Cela ferait du PLA le bioplastique le plus produit.

2. The main advantages of PLA

► Compostable

Many PLA products are degradable under industrial composting conditions (from +58°C) – much higher composting temperatures than compost in your garden. It is therefore important that PLA is always properly sorted and recycled so that it doesn’t remain in the environment for longer than it should.

To make sure that the bioplastic you are holding is compostable, you should look for the Seedling or TUV Austria logo. If this logo appears on the packaging, it can be industrially composted.

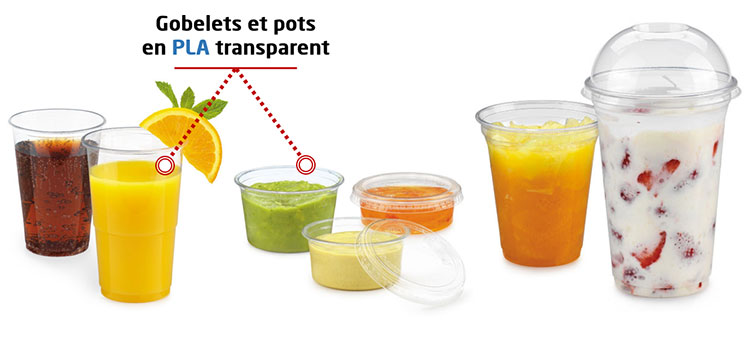

► Transparent

The second advantage of PLA is that it is transparent. Your packaged products remain perfectly visible. This is often a must when packaging food to show the appearance and quality of your vegetables, fruit or desserts. In addition, a dye can be added to PLA to make it opaque, if required.

► Flexible

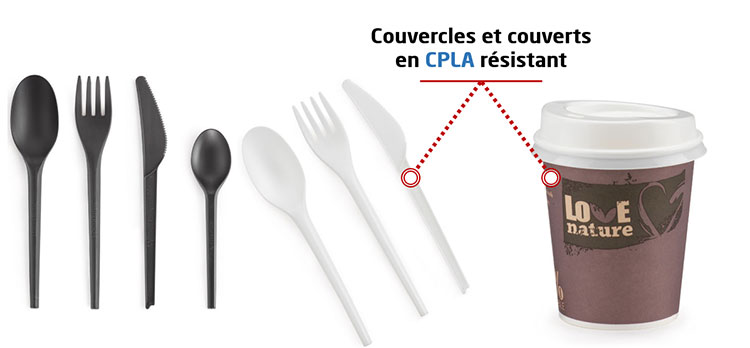

The third major advantage is its flexibility! It can be used for all kinds of products and packaging. The possibilities are almost endless. In addition, it can also be hardened with the addition of lime, for example. In this case we are talking about CPLA, where the C stands for crystallised. This ‘crystallised’ PLA is opaque and has a higher heat resistance.

- Firstly, a saving on fossil raw materials - a limited raw material. Bioplastics, on the other hand, use renewable biomass such as corn or sugar cane.

- The second advantage is that during growth, these plants absorb CO2 and release it as oxygen, so bioplastics have the unique ability to neutralise CO2

3. What are the applications of PLA?

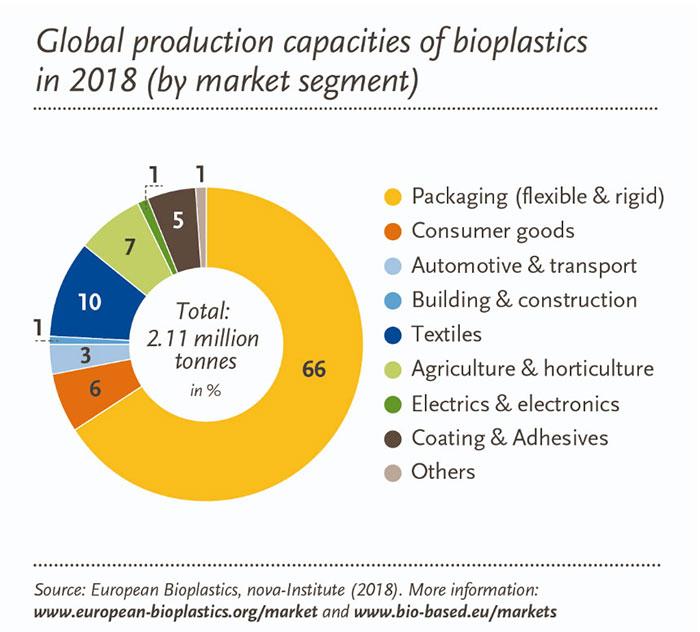

As the figure below shows, bioplastics are particularly popular in

the

packaging sector (66%).1 PLA, for example, is ideal for displaying and packaging food: fruit and vegetable pots, cups, sauce pots, etc

Si vous souhaitez équiper votre cantine ou restaurant avec des couverts, tasses et gobelets durables, vous pouvez choisir la gamme PLA de RAJA ci-dessous. Pour les boissons ou aliments frais, il est préférable d’utiliser du PLA standard, tandis que pour les boissons ou aliments chauds, nous recommandons l’utilisation de la version renforcée : le CPLA.

Les bioplastiques existent sous les formes les plus diverses. Chez RAJA, par exemple, nous utilisons des films bio pour protéger nos catalogues expédiés. Ce film est fabriqué à partir de canne à sucre. Il est recyclable à 100 % avec les plastiques traditionnels LDPE. Il est d’ailleurs bien plus écologique grâce au fait qu’il provienne de déchets végétaux.

Les bioplastiques existent sous les formes les plus diverses. Chez RAJA, par exemple, nous utilisons des films bio pour protéger nos catalogues expédiés. Ce film est fabriqué à partir de canne à sucre. Il est recyclable à 100 % avec les plastiques traditionnels LDPE. Il est d’ailleurs bien plus écologique grâce au fait qu’il provienne de déchets végétaux.