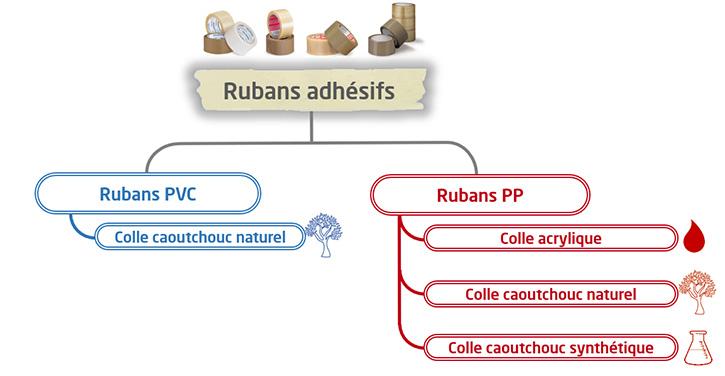

An adhesive tape consists of only 2 components: a backing and an adhesive layer.This backing can be made of PP (polypropylene), PVC or paper.In this article we will mainly look at the difference between the first 2 variants: PP tape and PVC tape.They are both made of plastic and are the most popular today.They can be used for a wide range of applications.However, if you want to know more about paper tapes, read this article.

1. How can you tell the difference between PP and PVC tape?

If you have a PP and a PVC tape in your possession, it is possible to compare the transparency between the 2: you will see that the PVC tape is often much more matte than the PP version.

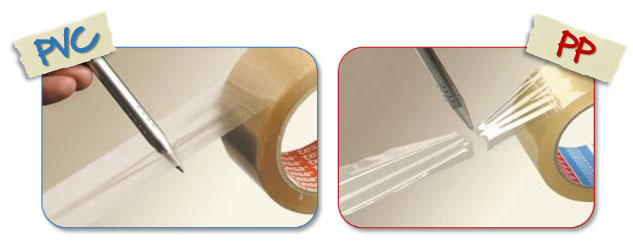

Another way to tell the difference between the 2 is via a simple stretch test. Proceed as follows: unroll a piece of tape, stick one end to your desk, and hold the other end firmly in your hand. Take a pen and poke it into the middle of the stretched tape. 2 scenarios are possible

PVC Tape = The pen will only make a hole in your tape due to its high elasticity.

PVC Tape = The pen will only make a hole in your tape due to its high elasticity. pP tape = If you pierce it with a pen, the tape will crack or tear completely.

pP tape = If you pierce it with a pen, the tape will crack or tear completely.

2. All differences at a glance

| PVC Tape |

PP Tape |

| Quiet unwinding | Non-silent or low noise unwinding |

| Elastic | Rigid |

| Transparency: matt | Transparency: clear |

| Adhesive: natural rubber | Adhesive: acrylic, natural or synthetic rubber |

| Use: for medium and heavy packagesup to ± 30 to 40 kg | Use: for light parcelsup to ± 20 to 30 kg |

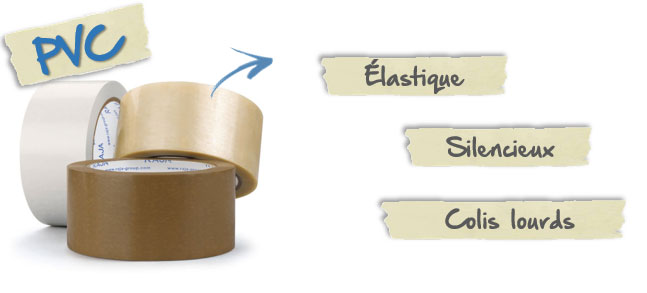

3. Characteristics of the PVC tape

PVC used to be the standard in the world of packaging tapes. Although it is increasingly being replaced by PP tape, PVC is still the most versatile variant on the market. And all thanks to these properties

- For medium and heavy packages up to ± 30 to 40 kg.

- Silent : when unrolling, it is much quieter than its standard PP counterpart. For people who have to close boxes all day, this is much more pleasant.

- Elastic as the above test showed, PVC is much more elastic than PP. This makes PVC tape very versatile. The downside is that PVC can never be torn off by hand. A pair of scissors or a tape dispenser is essential.

- Matte transparency : the tape is not completely transparent and may even look a little yellowish.

- Glue layer : lpVC tapesalways have an adhesive layer of strong natural rubber glue, see below for more information (5).

4. Characteristics of PP tape

PP stands for polypropylene, one of the many variants of plastic. Today, it is the most widely used tape in the packaging world. The fact that it is slightly cheaper than PVC tape has a lot to do with this. However, the cheaper purchase price is not the only positive feature of this tape

- For light packages up to ± 20 to 30 kg.

- Non-silent or low noise: in its cheapest standard version, PP tape is not quiet. When unrolling, it emits a shrill sound of about 75 decibels. That is as much noise as a passing car. Fortunately, there are also quiet versions. This low noise tape only reaches 60 decibels when unrolling.

- Rigid : this type of tape is much stiffer in its structure and therefore breaks easily if you apply the elasticity test. The advantage is that it is easier to tear off by hand.

- Clear transparency : in addition to the well-known brown varieties, there are also perfectly clear and transparent varieties. Let’s say you have a box printed with your company logo, then a transparent PP tape will be more suitable to keep it clearly visible.

- Glue layer the standard version of PP tape usually has rubber adhesive, while the silent version is more often acrylic adhesive.

5. What kind of glue is used for plastic tapes?

As mentioned in the introduction, glue is one of the basic components of adhesive tape, and there are 3 variants

-

Acrylic glue: is made from water. It always remains transparent and does not yellow. This glue is often combined with alow-noise PP tape.

-

Natural rubber glue: this is also known as solvent glue. Solvent-based adhesives have a very strong adhesion. They are the most versatile (think of outdoor use) and are more resistant to low temperatures. They can be used in combination with PP and PVC.

-

Synthetic rubber glue: This third form is also called hotmelt glue. It is the cheapest variant. It is less often used for export as it is not very resistant to temperature variations. This glue is the best in the short term, so it is very suitable for e-commerce applications, for example, as these packages always have to be delivered within a short time. It is only used with standard PP tapes.

6. How recyclable is plastic tape?

PP and PVC are both plastic.Oil is the raw material.The good news is that this raw material is easy to recycle.The “not so good” news is that you are still forced to separate the different types of plastic from each other.This makes for the best possible recycling.

If your plastic tape is glued to a cardboard box,make sure that it is removed from the box first.For cardboard recycling,however,there is a tolerance of 3% impurities.This means,in practical terms,that a little bit of plastic on your box does not interfere with the recycling process.

7. Adhesive tape: a story that sticks everywhere

Les rubans adhésifs dont nous avons parlé plus haut sont nés dans le secteur de la cosmétique. C’est peut-être un peu étrange si l’on considère qu’aujourd’hui ils sont principalement utilisés dans de nombreux autres secteurs que la cosmétique.

L’histoire remonte au début du XXe siècle, dans l’entreprise allemande Beiersdorf: un fabricant de produits de soins pour la peau, plus connu pour les marques Nivea et Eucerin, par exemple. De leur recherche d’une solution pour protéger durablement la peau est né le sparadrap. Après la conception de ce dernier, il n’y avait qu’un pas à faire vers le développement du ruban adhésif. Et voilà… grâce à un pot de crème pour le visage, vous pouvez aujourd’hui fermer vos caisses.