Did you know that there are more pallets in circulation in Europe than people? According to the latest count (in 2015), there were 3 billion pallets in the EU. That’s 4 per capita. Wooden or wood fibre versions are the most popular. The explanation can be found in the international standard ISPM15. Read on to find out what exactly this means and check your knowledge of the rules, types and benefits of wooden pallets.

1. What is ISPM15?

Wood is a natural product and can therefore harbour living organisms. Of course, it is best to keep harmful pests or bacteria out of the borders. The'International Plant Protection Convention or IPPC has found a solution to this problem. All wood packaging materials used for export must meet the so-called ISPM15 standard.

ISPM stands for International Standards for Phytosanitary Measures. The number 15 simply refers to the 15th measure in a longer list of standards set by the IPPC. Wooden packaging meeting this standard has undergone a special treatment process (often heat treatment). They are free of harmful organisms and are safe for export.

2. How are wooden pallets treated?

Since 2015, heat treatment or Heat Treatment (HT) is the only treatment suitable for use in general applications such as storage and transport. The wood packaging material is heated according to a specific time and temperature schedule, so that the core and overall profile of the wood reaches at least +56°C for a minimum of 30 minutes. This treatment method is effective in killing many forms of harmful life such as insects and worms.

.

3. What is the marking of a treated pallet?

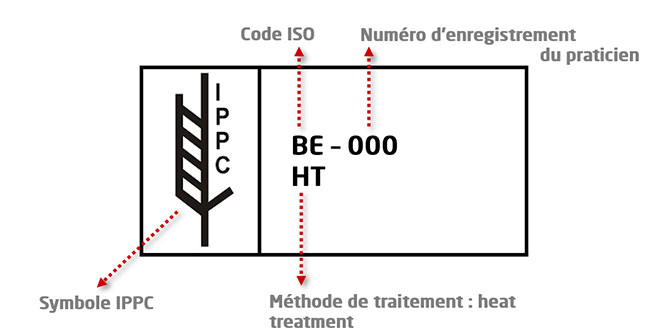

After treatment, wooden packages are indelibly marked with a special symbol, represented in the form of a herringbone and a sequence of numbers and figures on the right. They must always be placed legibly on at least two opposite sides of the product. On this symbol you will find the following information

- The ISO code of the country where the wood was treated, e.g. BE or FR.

- The registration number of the practitioner.

- HT / DH / MB : this refers to the method of treating the wood. Some examples are Heat Treatment (HT), Dielectric Heating (DH) and Methyl Bromide (MB).

Good to know: the additional designation DB is often found on old wooden packaging. It means “debarked” (debarked). However, debarking has meanwhile become a mandatory measure, so this marking is no longer shown separately.

4. Does ISPM15 apply to all packaging?

The ISPM15 standard is mandatory in a growing number of countries. The standard applies to all wood packaging materials. However, there are some exceptions to this rule. For example, the materials listed below have already been exposed to very high temperatures during their manufacture, so that separate treatment is no longer necessary.

The standard applies to all wood packaging materials.

- Wood packaging that has been glued, heat treated or pressed during processing, such as particleboard, plywood and veneer sheets.

- Wooden parts permanently attached to trucks and containers.

- Wood packaging material consisting of fine wood up to 6 mm.

Environmentally friendly, ideal for export, very strong… These are just a few of the advantages mentioned when talking about wooden pallets. For the sake of completeness, we list them all: Wood has exceptional properties, both logistically and ecologically. Wood is a natural raw material from forests. And what is the great advantage of trees? You can plant them, let them grow and cut them in an almost endless cycle. So they don’t deplete natural resources. Has your wooden pallet run its course? You can easily recycle it. Who knows, maybe the next crate you use will be made of your old pallets? Closing the raw materials loop – that’s what it’s all about. The type of wood from which pallets are made has a high density. This makes it resistant to high pressure and capable of bearing heavy weights – up to 1,500 kg. Conclusion: if you are shipping heavy goods, use wooden pallets instead of wood fibre or cardboard pallets. Do you want to know what wood fibre or cardboard is used for? Check out our General guide to choosing pallets here. With a wooden pallet, you give your load an extremely stable base. The weight is optimally distributed thanks to the long, flat “sleds” at the bottom of the pallet. In addition, wood is a material that is inherently non-slip. It therefore reduces the risk of the load shifting and falling off the pallet. When it comes to load securing, it is therefore best to use wooden pallets. Wooden pallets are immensely popular in the world of import and export. Their sizes are standardised around the world, making it easy to exchange them between companies. However, as we have already described, this globalisation carries a risk: wood can harbour a whole colony of parasites and micro-organisms that transmit diseases from one continent to another. To prevent this risk, the ISPM15 standard was developed. Wooden pallets bearing this label have been treated in such a way that they are now export-compliant. Wooden pallets are made from different types of wood. Oak is often used for the load-bearing parts. Pine (or fir) is used in the other parts.

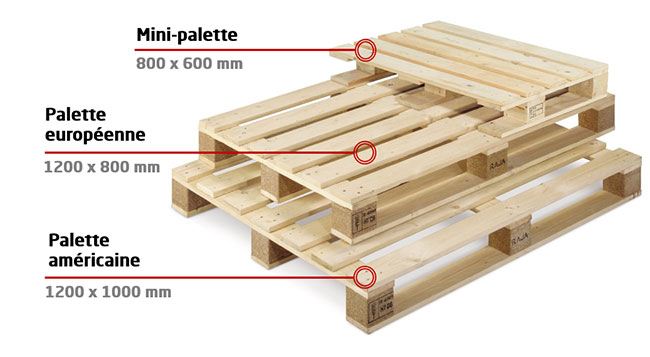

In the world of pallets, there are traditionally two sizes: the American and the European size. The American format is 1200 x 1000 mm and is mainly used in the USA, Canada and Japan. The European format is 1200 x 800 mm. This size is perfectly compatible with most European trucks. Finally, there is also the “mini-pallet”. This is the little brother of the European pallet and is usually only found in Europe. Good to know: the European pallet and the mini-pallet often carry the EUR or EPAL logo. * The maximum load mentioned here always refers to the dynamic load of your load. To find out what this means exactly, check out our Guide to choosing pallets here.5. What are the advantages of wooden pallets?

5.1 Environmentally friendly

5.2 Robustness

5.3 Stability

5.4 Ideal for export

6. What are the types of wooden pallets?

Maximum load*

European palette

Mini-pallet

American palette

Up to 1500 kg

1200 x 800 mm

Up to 1000 kg

1200 x 800 mm

1200 x 1000 mm

Up to 800 kg

1200 x 800 mm

Up to 600 kg

800 x 600 mm

Attachments