Did you know that almost 80% of consumers prefer cardboard packaging to plastic packaging? And that 75% of them are prepared to pay a higher price for environmentally friendly packaging (Pro Carton 2021 study)? It’s a fact: for both your brand image and your CSR strategy, it’s crucial that you find eco-friendly packaging alternatives to traditional packaging that have a negative impact on the planet.

To help you, we’ve put together this top 7 list of eco-responsible packaging that will inspire you to devise a more environmentally virtuous logistics strategy.

1. Packaging that uses less material

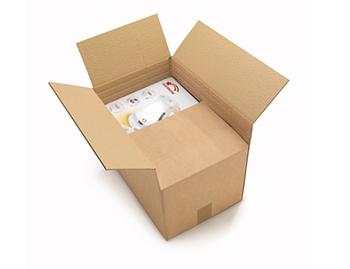

Reducing the weight-volume of your packaging is probably the easiest way to pack your products in an environmentally-friendly way. By limiting the volumetric weight of your shipments, you limit the empty space in your packages, and therefore optimise the filling of lorries during transport. Another interesting point for your company: by doing so, you also limit your express and international shipping costs.

It is possible to work on reducing the weight/volume of all types of packaging, by adapting the containers chosen to the size, weight and need for protection of the goods.

|

Innovations in this area include the variable-height body. The principle is simple: it has grooves that allow the cardboard box to be easily cut to adapt its height to that of your products. It’s so easy! |

2. Packaging that goes straight to the letterbox

What if, to make your packaging more environmentally friendly, you opted for packaging that goes straight through the letterbox on the first delivery round? This solution limits the number of rounds made by the postman. And, as well as being environmentally friendly, this packaging also enhances the customer experience, since your end customers don’t have to go to Bposte to get their parcel.

|

Some packaging is designed to fit standard letterbox sizes: this is the case with extra-flat boxes and postal cases. Make sure you choose this type of packaging so that it can be recycled: you will then have limited the carbon footprint of your shipments in the best possible way! |

|

If you’re sending non-fragile products such as textiles, use a paper shipping pouch. In many cases, they’re a perfect alternative to cardboard boxes. They’re lightweight, flexible and easily add an eco-friendly touch to your “last mile”. |

3. Ecological packaging that limits the impact of your returns

As you know, your customer returns have a significant impact on both your logistics costs and your carbon footprint. That’s why you need to do everything you can to limit them. And the good news is that packaging can help!

|

Visit return packaging is designed to withstand multiple shipments, limiting the use of other packaging by your customers when they want to return their products. Equipped with two tear-off strips, this packaging ensures secure shipping. |

4. Single-material ecological packaging

Single-material packaging is packaging made from a single material, which is much easier to recycle. Single-material packaging can be made from different types of raw material: plastic, glass, wood, paper, cardboard, etc.

|

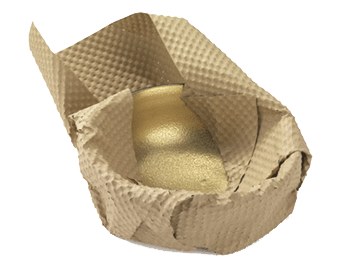

Paper and cardboard combined are the most popular monomaterials for packaging. The corrugated packaging paper from RAJA is an innovation worth mentioning. It’s a perfect alternative to plastic bubble wrap and can be sorted together with the cardboard box. A real must for your ecological packaging table! |

5. Transform your used cardboard boxes into brand new cushioning

Imagine giving new life to waste yourself! Do you have piles of used cardboard boxes all over your warehouse? And do you occasionally need paper padding to fill your parcels? If so, consider buying a cardboard padding machine. You can easily transform your used cardboard boxes into high-quality protective cushions.

|

The cardboard padders are an environmentally-friendly solution for any packaging environment. All you have to do is recycle your cardboard waste yourself. This way, you’ll need far fewer raw materials and save a bit of money by buying less packaging material. |

6. Pack with natural raw materials

When we talk about natural packaging materials, we automatically think of paper and cardboard. The wood from which they are made is, of course, completely environmentally friendly and easily renewable (provided we manage our forests consciously). In recent years, innovations in environmentally-friendly packaging have made it possible to add many other natural raw materials. Grass paper and vegetable starch are good examples. Which innovation would you choose?

|

A crate made of grass may seem far-fetched, but it’s not at all. The use of grass as a raw material is a relatively new technique that is making increasing inroads into the world of packaging. Grass paper boxes are just as strong as standard boxes. What’s more, they require less water and CO2 emissions to produce. Ecology in full swing! |

|

Using vegetable starch as a packaging material? It’s possible! Take a look at Flo-Pak Natural. They are made from 100% air, water and starch. An ecological trio. The cushioning particles are strong enough to absorb shocks and protect your products. |

7. Reuse packaging

Reusing packaging not once, but twice, three or four times (or even more often) is undoubtedly one of the best ways of making it truly future-proof. So it’s hardly surprising that this concept features prominently in the new European packaging law. But for packaging to be truly reusable, the logistics sector will have to learn to adapt on a sufficiently large scale. Fortunately, a lot is being done behind the scenes to make this happen. RAJA Belgium is doing its bit.

RAJA is actively working on new solutions to market packaging that is strong enough, easy to fold and compact enough to be returned. Preferably, this type of packaging will also be renewable and recyclable. We are particularly interested in cardboard-based innovations. We plan to launch the first commercial solutions on the Belgian and Dutch markets during 2023.

Can’t wait and would like more information now? Contact us and we’ll be happy to explain our progress (012 260 280 or sales@rajapack.be).