Shrinking a pallet is an essential stage in palletising, enabling your goods to be shipped securely. But it can be a complex task for your operators, especially when it’s done manually. Find out here about 7 bad practices to eradicate in your logistics warehouse, so that your pallets are filmed to perfection, in optimum safety conditions.

Tip 1: Choose your manual palletising equipment carefully

Before you even think about how best to film a pallet manually, have you chosen your equipment carefully? This is an essential element in making the palletising process less complex for your operators. So make sure you choose :

- The right type of pallet pallet. Take into account its maximum load, its number of entries and also its size, all of which depend on the type of goods you are palletising .

- The right type of boxes. Think about palletisable boxes, which are specially designed to be filmed into pallets.

- The right type of stretch film, really suited to filming a pallet by hand. For medium-sized pallets with shallow corners, we recommend choosing pre-stretched blown film: it makes manual palletising effortless for your order-pickers.

Tip 2: Stack products in a stable manner

Here’s one of the most common mistakes. If your boxes are unstable on your pallet, the pallet itself will not be stable, and you risk damaging the goods during transport.

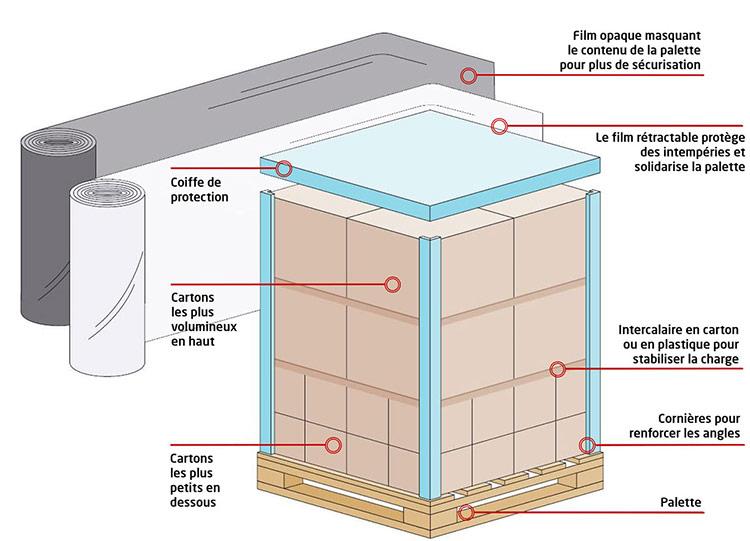

So start by stacking the boxes in a stable way, placing the smallest at the bottom of the pallet. Don’t leave any gaps between the various boxes, and place cardboard spacers between them: this is the guarantee of a really stable pallet, which will be easier to film and transport later on.

RAJA’s extra tip: you can use a pallet box, which allows you to respect the maximum dimensions of the pallet, so that the cardboard does not spill over the sides. Think about implementing this process, especially if you have a lot of temporary workers in your warehouse, and don’t have the time to train them and assess the quality of their pallets.

Tip 3: Shoot the palette in the right direction

Your stretch film has a specific direction of application: its sticky side should be placed against the pallet boxes, and its smooth side facing outwards. Some rolls of film run clockwise, others counter-clockwise.

Filming a pallet in the wrong direction entails risks that should be avoided at all costs. Firstly, the film will not hold if the sticky side is not positioned towards the boxes; secondly, your pallet will not be protected from dust and any other storage conditions that could damage it. So make sure you train your operators to apply the pre-stretch film correctly.

Tip 4: Pack the pallet evenly

When filming a pallet manually, you need to make sure that every part of the pallet is wrapped, filmed, evenly. We recommend wrapping the pallet with 10 to 20 cm of film on each strip, for optimum protection.

If you don’t take care to do this, your pallet is likely to be weakened in the areas that are less filmed, more exposed to storage conditions and to shocks during transport, and therefore potentially damage your goods.

Tip 5: Protect your pallet from the weather

Are your pallets stored outside, or in an area subject to environmental conditions that can damage them? Think about protecting them! The choice of pallet itself can depend on these storage conditions: plastic pallets are waterproof, while moulded pallets are insensitive to temperature variations.

But you should also think about adding additional elements to protect it from the elements:

- Use a pallet cap, which fits over the pallet, to protect it from the weather.

- Opaque black film provides better protection from light… and from the temptation of theft, since your goods are hidden from prying eyes.

Tip 6: Install appropriate signage in the warehouse

Filming a pallet and handling it are tasks that place particular demands on your operators’ bodies, and are not without risks to their health. To ensure optimum safety in your logistics warehouse, take care topost the right signage, which will help them to film and handle your pallets properly. Include :

- Optimum palletising rules, including good practice and the right equipment.

- Maximum palletised loads for each type of pallet used .

- Handling instructions: should the pallet be loaded on a pallet truck? On a forklift truck? Should they handle it manually, using gloves?

Tip 7: Take MSD risks into account

Wrapping and strapping pallets are tasks that present significant risks of Musculoskeletal Disorders (MS D) in the logistics warehouse. Poorly managed, these processes can lead to rotator cuff problems for your operators, and potentially increase absenteeism.

So how can you prevent RSI during palletising? If your operators film more than 12 to 15 pallets a day, it is advisable to equip yourself with a fully or semi-automatic filming/banding machine, which will put less strain on their bodies.