What is the purpose of plastic packaging? In recent years, we’ve seen a marked change in the way companies deal with this material. It’s true that we’re all more critical than we were ten years ago, for example. However, plastic still has many advantages as a packaging material: it is strong, flexible or rigid, and can be easily adapted to all types of products, at a very modest price.

But can plastic really be sustainable for our planet? And which plastics should we choose? Read on to find out more.

1. Plastic packaging is essential for certain products

Is plastic packaging useful? For some companies and sectors, the answer is a resounding yes! After all, in many cases it is now the only material capable of perfectly protecting a product during storage or transport. Plastic has protective properties that remain necessary in certain sectors, in the absence of a good alternative. Just think of its resistance to moisture, oil and air. Here are a few concrete examples:

- Foodindustry = plastic packaging is used to package foodstuffs. Food keeps longer and food waste is reduced.

- Pharmaceuticalindustry = plastic is needed to isolate chemical or cosmetic products, or even samples for biological analysis.

- Transport = for products that are sensitive to corrosion or moisture, plastic is the most insulating material.

- The transport of hazardous products requires the use of LDPE plastic bags to isolate the goods from their outer container (made of wood or cardboard, for example).

2. Not all plastics are made from oil

When we think of plastics, we automatically think of the raw material oil. But plastics can also be made from very different materials. Thanks to all kinds of innovations in the packaging sector, companies can now package their products in environmentally-friendly plastics, also known as “bioplastics”.

Plastic packaging is generally made from naphtha, a crude oil distillate. This same raw material is also used in the production of fertilisers, perfumes and even medicines.1

Various natural substances can form the basis of a bioplastic. These can include starch (from maize, potatoes, rice or manioc), sugar cane, cotton cellulose,polylactic acid (PLA), etc. A well-known example is Flo-pak Natural cushioning particles, made entirely from vegetable starch. When they come into contact with water, they decompose without leaving any residual waste. The great advantage of bioplastics is that the plants that make them up filter CO2 from the air as they grow. This bioplastic therefore effectively neutralises this CO2.

If you want to recycle bioplastics, you need to be careful… As a general rule, you should not dispose of these plastics with organic waste or in a PMC bag. If you do, it can interfere with the recycling process. It is therefore preferable to sort these materials as residual waste. It’s good to know that incinerating bioplastics with residual waste has less impact than incinerating petrochemical plastics.

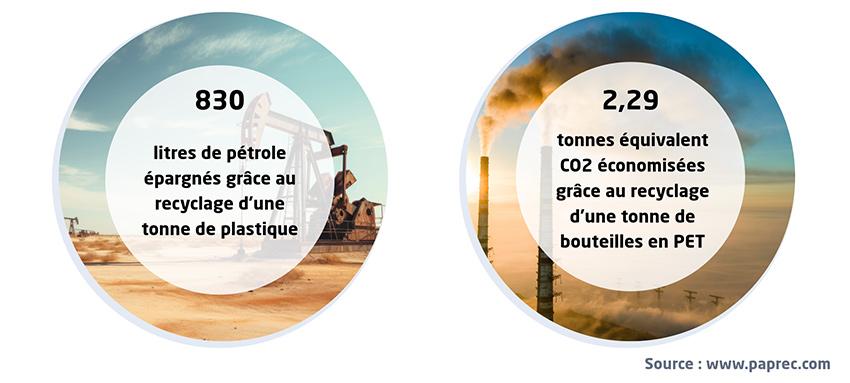

3. Plastics can be recycled too

Many plastics are perfectly recyclable (in the appropriate recycling circuits). They can then be reprocessed into new materials. In this way, the raw materials cycle is closed and the need for new oil is significantly reduced.

We also note that the EU attaches great importance to the recycling of plastics. This is reflected, for example, in the new PPWR (Packaging and Packaging Waste Regulation) legislation. Under these new rules (which are still being drafted), from 1 January 2030 plastic packaging will have to contain a minimum quantity of recycled materials. Otherwise, it will not be allowed to be placed on the market. Europe is also aiming to step up plastic collection. The aim is to recycle up to 50% of all plastics by 2025, and 55% by 2030.

Correctly sorting plastic packaging is a crucial stage in the cycle. This is where companies and consumers have a major responsibility. What are the easiest (and most difficult) plastics to recycle? We took a look at them as follows:

Polyethylene terephthalate |

. Recyclable Recyclable |

. Used for food packaging, soft drinks bottles, cushioning, etc. |

High density polyethylene |

. Recyclable Recyclable |

. Used for water, milk and shampoo bottles, soft drink caps, etc. |

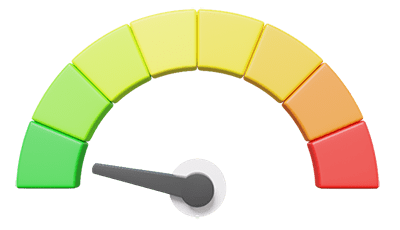

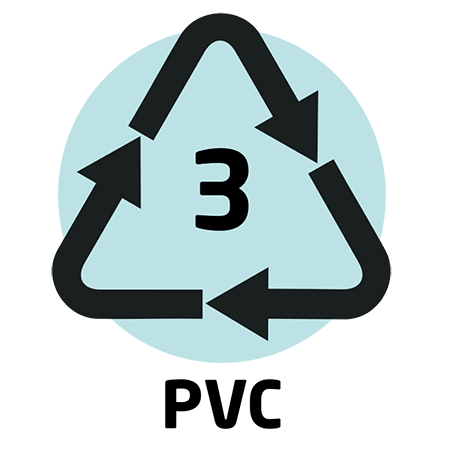

Polyvinylchloride |

. Difficult to recycle Difficult to recycle |

. Used for adhesive tape, plastic window frames, kitchen utensil handles, garden furniture, etc. |

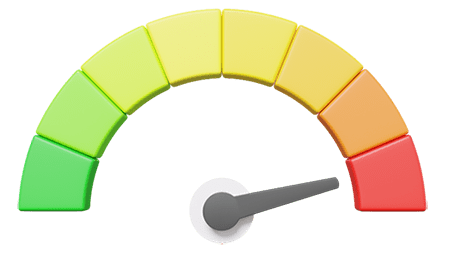

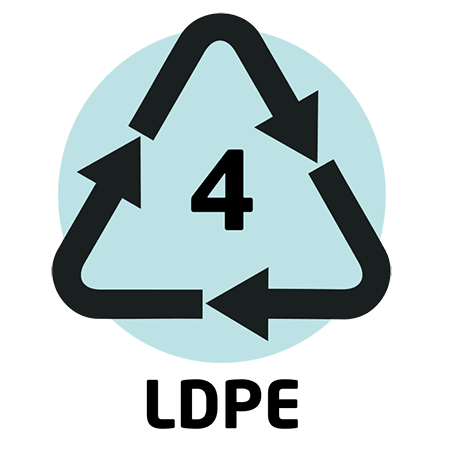

Low-density polyethylene |

. Recyclable Recyclable |

. Used for bin liners, stretch film, plastic bags, etc. |

Polypropylene |

. Recyclable* . Recyclable* . |

. Used for adhesive tapes, synthetic carpets, children’s crockery, microwave dishes, etc. |

Polystyrene |

. Difficult to recycle Difficult to recycle |

. Used for foam (in meat packaging) |

* The reality is that there are few PP materials available for recycling. As a result, the few PP materials that are collected often end up in the incineration cycle.

Good to know: to simplify the recycling process, it is preferable to choose single-material packaging. This ” single-material packaging ” is made from a single raw material. This may be plastic, but also cardboard, aluminium, wood, etc. By choosing a single raw material, the packaging can be sorted and recycled more easily.

4. The cardboard alternative also has its limits

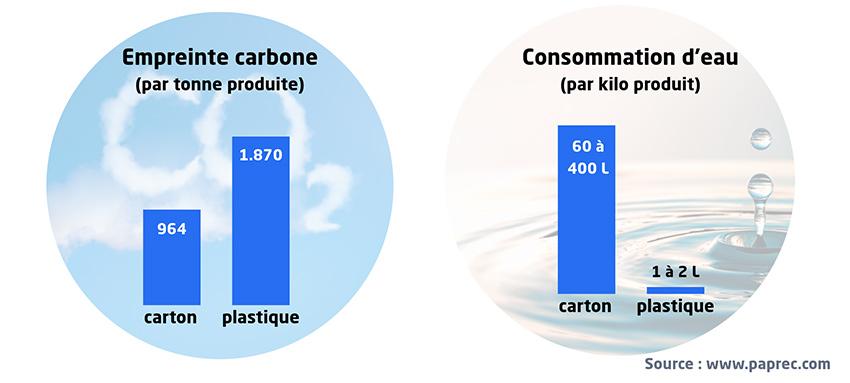

If we had to replace plastic packaging, what would the alternative be? In most cases, cardboard is chosen. But what about the ecological impact of these two materials? 1

As the above comparison shows, cardboard performs better in terms of its carbon footprint. Plastic, on the other hand, is a better choice in terms of water consumption. If you take a critical look at the production process for these two materials, you’ll see that they each have their advantages and disadvantages.

You may also be wondering whether a cardboard box is always a good shipping solution. For less delicate products such as textiles or clothing, it is often preferable to use a shipping bag. Such a plastic carrier bag allows products to be packed very compactly, without any extra air inside. What’s more, thanks to the thin layer of plastic, the items are optimally protected against water and moisture.

5. Plastic packaging can be reused

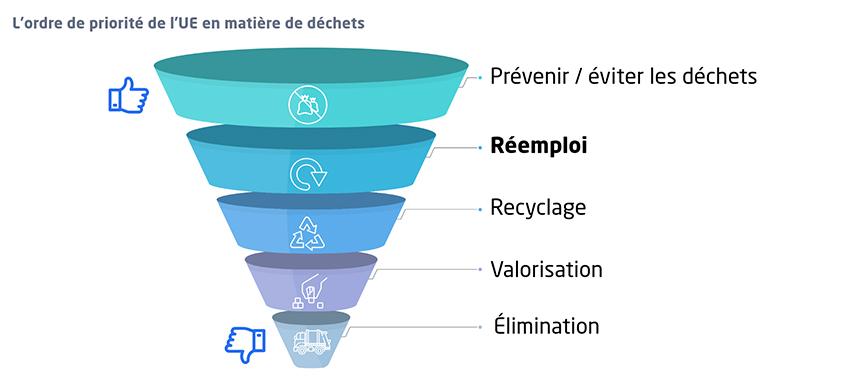

Single-use plastic products and packaging are systematically banned in Europe. Year after year, the EU imposes new rules on single-use plastics. Just think of the ban on thin plastic carrier bags, plastic straws and so on. However, the future of plastics lies in the fact that they are perfectly reusable. That’s where it excels. In fact, EU policy goes a long way towards encouraging the reuse of packaging.2

Fabrice Peltier, designer and eco-design consultant, said in a recent interview with RAJA: “It’s not so much the plastic itself that poses a problem, but above all the lack of proper sorting and recycling. So we need to simplify packaging, for example by opting for single-material packaging. More than ever, the packaging of the future must be the right packaging, adapted to your products: choose the right material, the right dimensions, the right weight, and so on. Today, we live in an age of excess: too many options, too much packaging, too much consumption. We need to learn to reuse packaging more often and recycle it more easily, so as to reduce the overall consumption of resources in Europe”.

As Fabrice Peltier points out, the great strength of plastic lies in its reusability. Reusing plastic packaging in a “closed circuit” will quickly have a major positive impact. With this in mind, many logistics companies, for example, are deliberately choosing solid plastic solutions to equip their warehouses. Here are just a few of these popular products.

Spout bins |

European standard bins |

Plastic pallets |

| These bins are resistant to oil, grease and wide temperature variations, making them a good alternative to cardboard bins. | These stackable bins can easily be placed on pallets. They are strong, practical and recyclable. | Plastic pallets are an ideal solution for storing and transporting products. They are as robust as they are durable. |

In a nutshell

We realise that we need to optimise the packaging. Not too much, not too little. This means taking a critical look at the materials used. How can you best protect your products and what kind of customer experience do you want to offer? Some companies simply can’t do without plastic to package their products. We have seen that it is also possible to opt for bio-based solutions or forms of recycled plastic. These are excellent alternatives for protecting your products effectively and attractively.

It’s up to you to ask yourself the right questions and make your logistics as environmentally friendly as possible. RAJA will be happy to discuss this with you.

As Europe's largest packaging distributor, RAJA is at the forefront when it comes to innovations and new solutions. Sustainability always plays an important role for us. Almost every new product we offer has an ecological aspect to some extent. For example, several years ago we phased out polystyrene packaging and replaced it with recycled PE plastic alternatives or paper and board innovations. In addition, much of our existing plastic packaging has been replaced by recycled plastic alternatives.

Wim Gielis, Product Program Manager at RAJA BeneluxBronnen:

1 www.paprec.com

2 www.consilium.europa.eu