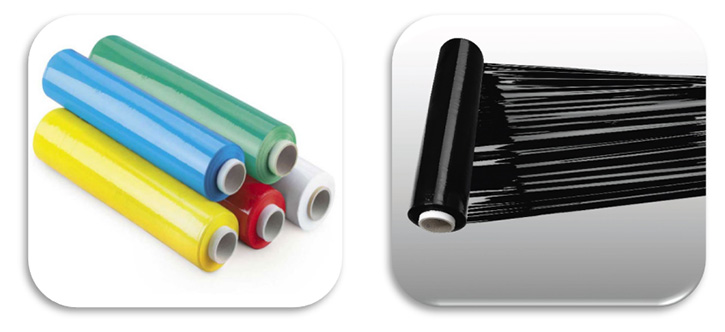

The first stretch film you think of straight away is probably clear. am I right, no? This film is obviously the best known of its kind. But there are so many others. In fact, there is a wide range of colours and types available. Below we teach you how to use coloured stretch film to more easily identify your pallets, protect them from theft, etc.

1. Why use stretch film?

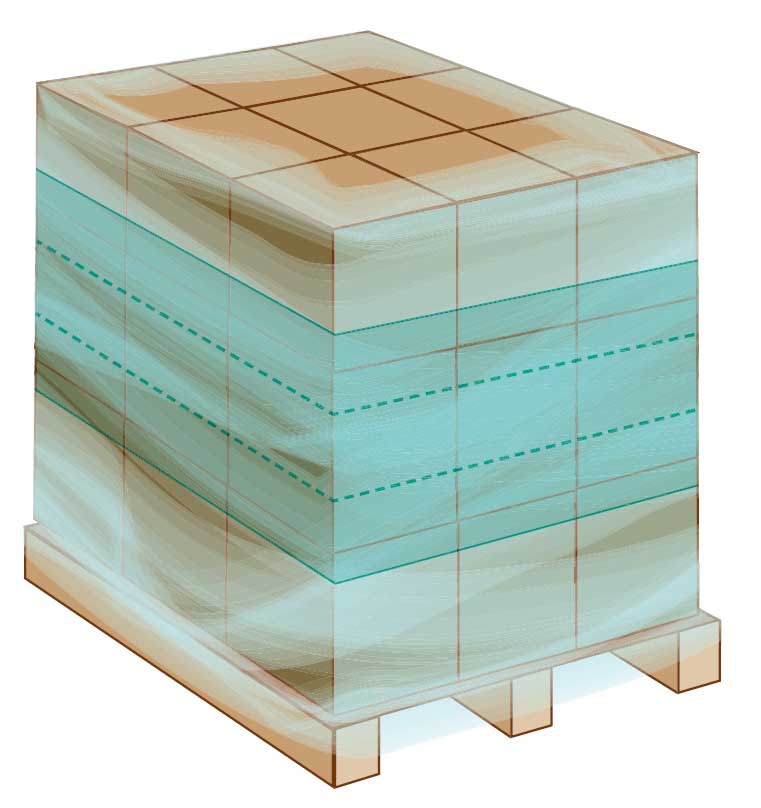

Stretch film is essential when transporting goods on pallets.By wrapping your pallets in stretch film, you ensure that your products are transported safely: they will not move on the pallet and will also be protected from dust, dirt and moisture.Ideally, every pallet that leaves your warehouse should be covered with a solid layer of stretch film to protect it.In this article, you will read all about thecorrect use of stretch film.

2. The advantages of coloured stretch film

Le film d’emballage est transparent par défaut. Grâce à cela, vous savez immédiatement quelles marchandises sont emballées sur votre palette.

► Le film étirable peut également être noir, opaque. Ce film est utilisé pour protéger vos produits contre le vol pendant le transport, le stockage ou le transfert de ceux-ci. La couleur foncée du film garantit à votre palette une parfaite opacité. Ainsi, le contenu de vos envois reste confidentiel et vous attirez moins l’attention des voleurs. Le film noir existe également sous la forme d’une coiffe protectrice que le magasinier place sur ses produits pour les cacher.

► En plus de la couleur noire, le film étirable est également vendu en 5 couleurs vives. Cela vous permet de reconnaître vos palettes d’un seul coup d’œil ! Ce film étirable est disponible en bleu, rouge, jaune, vert et blanc. Les couleurs vives du film vous permettent de reconnaître plus facilement vos palettes et vos marchandises. Vous pouvez, par exemple, faire corre

- There is also the antistatic stretch filmit provides optimum protection for your electronic devices and components.

- The flexnet stretch film is equipped with holes that allow your goods to be optimally ventilated, which is an important protection as it prevents condensation from forming.

- With a pre-stretched filmwith the use of the film, you save considerably on your total film consumption, as you need fewer metres of film to cover and protect the same area[/su_box]

su_spacer]

3. Manual or mechanical stretch film?

Clear or coloured stretch film can be applied in one of two ways: manually using an unwinder or mechanically using a wrapping machine. If you need to wrap more than 15 pallets a day, it’s best to choose a machine to make your job easier.

► Manually

For businesses that only prepare a few pallets a day, you can simply choose a manual unwrapper. This is probably the most cost-effective solution. Take a look at how toproperly apply your stretch wrap in this article.

► Machinally

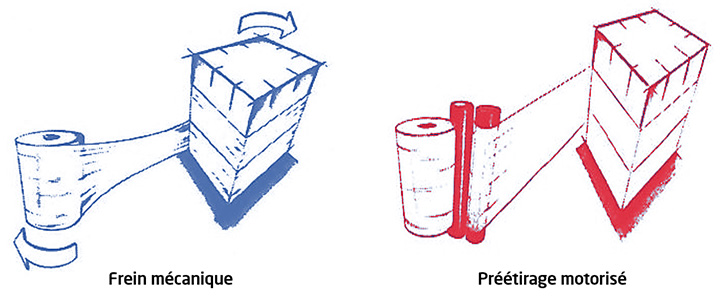

Ifyou pack more than 15 pallets a day, you should choose a stretch wrapper. This machine will save your warehouse worker valuable time and you will also save on your stretch film consumption. The machine never uses more film than necessary. In general, there are two types of stretch wrappers: one with a mechanical brake system, or one with a motorised pre-stretch

- System with mechanical brake= those with a brake system are technically the simplest and therefore also the cheapest. The film is stretched with the help of a brake (up to a maximum of 100%). The result is that the film shrinks a little, so you will need more film per winding. To avoid this, it is advisable to use pre-stretched film.

- System with motorized pre-stretching = the machine pre-stretches the film optimally – up to 400%. The film rolls between two motorised axes that are placed very close to each other. The result of this process is a film that is no longer shrunk and covers your pallet as much as possible.

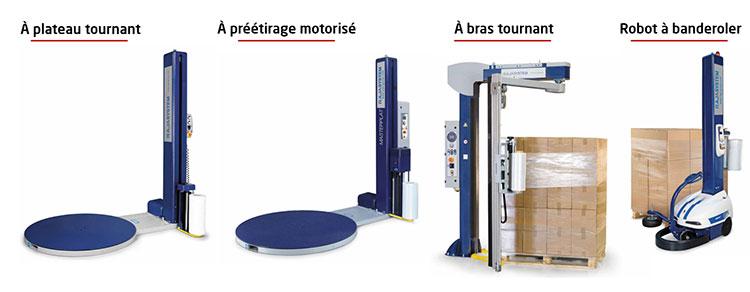

As you can see below, you can choose between several types:

Type of wrapping machine. |

Number of pallets & Type of load |

Advantage |

| (1) Mobile decoiler | –from 15 pallets per day–regular or irregular shaped load. | The most advantageous solution. |

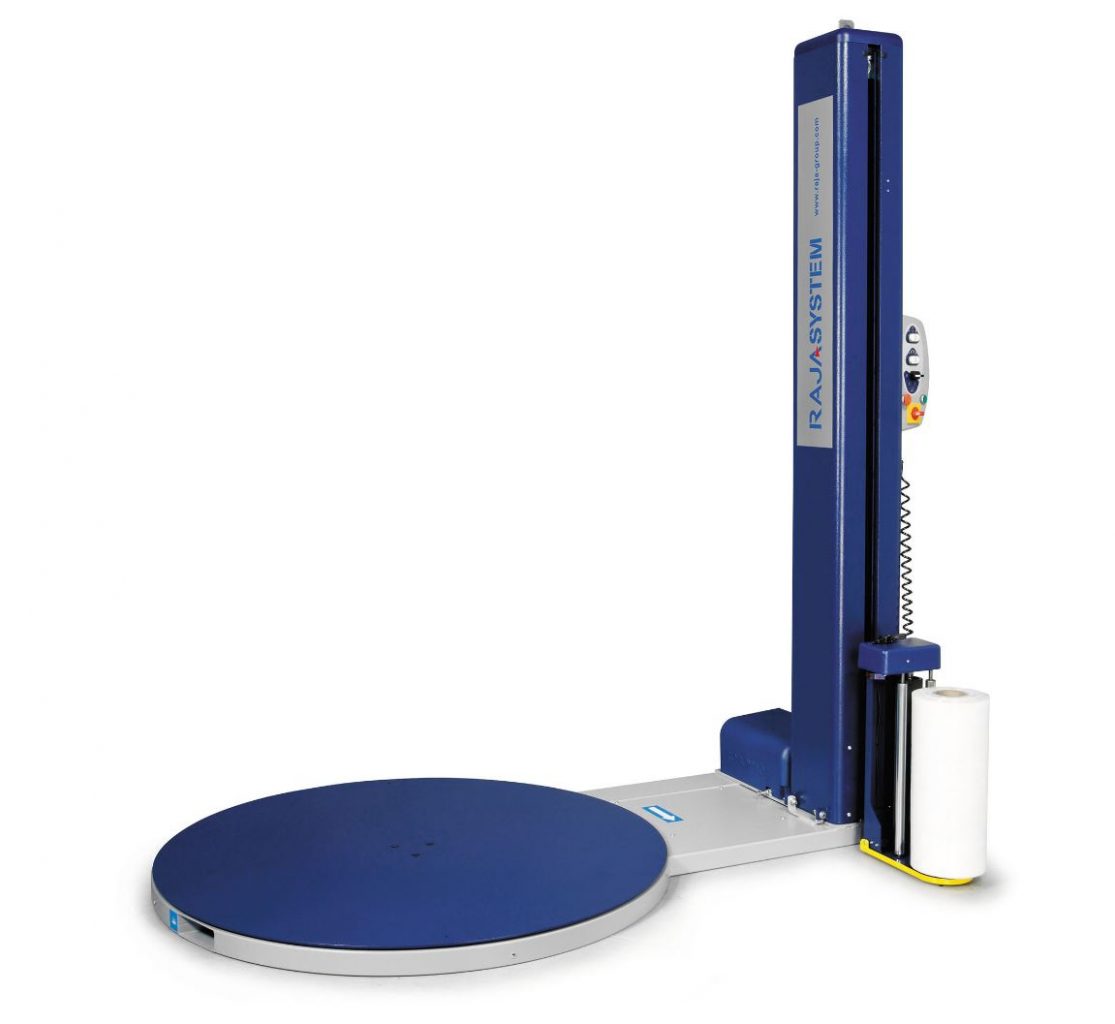

| (2) Turntable* | –< max. 50 pallets per day–regular shaped load. | The mechanical brake ensures even packaging. |

| (2) Turntable andmotorised pre-stretching** | –< max. 150 pallets per day–regular or irregular shaped load. | The pre-stretching ensures a max. economyon the amount of film used. |

| (3) Rotating arm* | –< max. 250 pallets per day–unstable loads and goods too heavy for a turntable. | With rotating arm that wraps the film around a very heavy pallet. |

| (4) Banding robot*** | –< max. 250 pallets per day–for loads which, due to their shape or weight, cannot be placed on the platform of a wrapping machine. | Automatically movingfor loads of at least 60 x 60 cm. |

as you can see below, there are several types to choose from:

* Equipped with a mechanical brake** Equipped with a motorised pre-stretch*** Your choice of mechanical brake or motorised pre-stretch