There are 3 methods to make your order processing easier and faster: manual, semi-automatic and automatic packaging. In this article we will mainly outline the pros and cons of the automatic method. What does it really mean and what benefits can you gain from it?

1. Automatic packing

With a fully automatic machine, the human being no longer has to intervene at all in the packaging process. The machine takes care of everything and does it its own way

| Advantages |

Disadvantages |

| ► It increases productivity: your employees can do other useful tasks at the same time.► It reduces stress: the machine rarely makes mistakes and frees your employees from the pressure of responsibilities.► It increases the quality of your packaging: they will all meet the same standards.► A machine never consumes more packaging material than is necessary, so less material will have to be purchased. | ► No matter how small, there is a risk of a technical defect, so regular maintenance is necessary.► Machines require a higher (one-off) investment. |

Toutes les étapes de votre processus d’emballages peuvent être dotées d’une solution automatisée, certaines plus grandes que d’autres. Il existe des machines conçues pour emballer et expédier automatiquement vos commandes. Elles s’assurent que vos commandes soient préparées beaucoup plus rapidement.

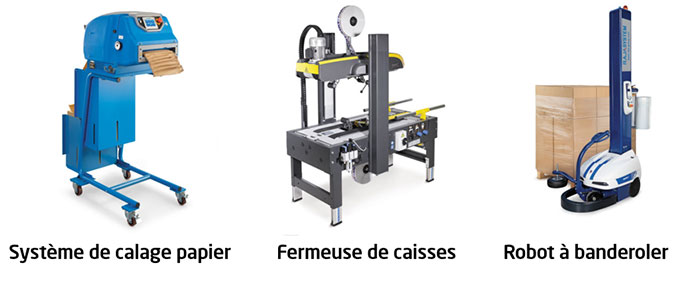

Les exemples les plus fréquemment utilisés sont les machines de calage papier ou de calage air. Il existe des modèles qui créent automatiquement du matériel de remplissage dès que vous n’en avez plus à disposition. Mais l’automatisation peut aller encore plus loin avec, par exemple, une machine de fermeture de caisses (que vous intégrez à un convoyeur) ou un robot à banderoler (pour emballer des palettes).

Dans la vidéo ci-dessous, nous vous montrons exactement comment fonctionne un robot à banderoler :

https://www.youtube.com/watch?v=uFOVic7qZis[

/embed] [su_spac

2. Semi-automatic packing

With the semi-automatic method, a person controls the machine. Without his control and (regular) intervention, the machine is not able to perform the work process correctly.

| Advantages |

Disadvantages |

| ► It improves the productivity of your employees► It increases the qualityand processing of your orders► It becomes easier to pack or transport medium volumes and quantities. | ► No matter how small, there is a risk of a technical defect, so regular maintenance is necessary.► Machines require a higher (one-time) investment. |

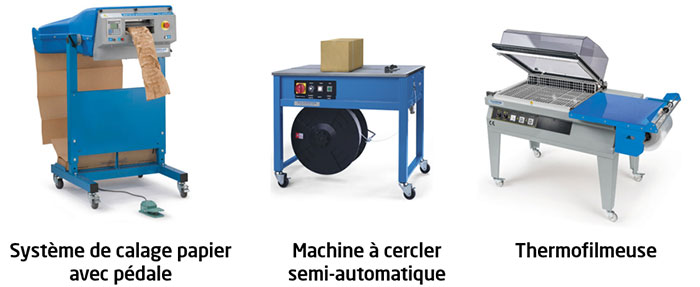

Semi-automatic machines require the (regular) presence of one of your employees.There are solutions for filling, closing or wrapping your packages.The automatic paper and air cushioning machines described above can also be used semi-automatically.This can be done via a remote control or foot pedal.This allows you to control the amount of cushioning that is made.

Other examples are semi-automatic strapping machines or heat sealers

.

An operator has to hand over the products each time and make sure that everything is going in the right direction.However, the machine does the bulk of the work for him.

3. Packing manually

Finally, a word of explanation about the manual process. Although there are no machines involved here, there are also options to make your work run more smoothly

| Advantages |

Disadvantages |

| ► You are not dependent on technical failures/interruptions► You can put the craftsmanship of your employees to good use. | ► Repetitive work can lead to errors► Manual packing can be a physical burden for your employees. |

With ‘clever packaging’ you work faster by hand. This kind of packaging is more intuitive, which means that your packer will be less stressed at their packing station. The examples below are often used in e-commerce

-

[1] Automatic bottom crate: by pressing on the side, your crate folds automatically and will be directly ready for use.

-

[2] Shipping crate or bag with integrated self-adhesive closure: Another solution to eliminate a number of actions is a self-adhesive closure, so you no longer need tape or a dispenser.

-

[3] Case or shipping bag with integrated cushioning: There are packages in which the cushioning is already present, such as padded pockets or cases with foam or film cushioning. This type of solution is often used for packaging clothing, fashion accessories or cosmetics.