Corrosion – or rust – occurs when metal is exposed to moisture. This causes iron and steel to discolour and lose quality. Nothing positive. Does your company often ship metal parts that are susceptible to rust? If so, don’t forget to add good corrosion protection. A simple “VCI package” can do the trick. Read below to find out how it works.

1. What is corrosion and what risks does it pose?

“Corrosion” is a generic word for any form of chemical attack on materials. This reaction has a negative effect on the quality of the material. The material

- will become weaker,

- reduce in volume,

- become discoloured.

one specific form of corrosion is rust.It occurs when iron (steel) is attacked by oxygen and water.The iron oxidises and turns a reddish-brown colour.Corrosion can also occur with copper (which will turn green),aluminium (which will have a whitish colour) orsilver (which will turn black on contact with sulphur).Corrosion protection ensures that the quality of your products is maintained.This protection is therefore absolutely essential.

2. How does corrosion occur?

Corrosion occurs when a metal is exposed to oxygen and water, so we definitely want to avoid the formation of moisture. It is imperative to pay special attention to corrosion protection in 2 situations in particular:

► Overseas transport

When transporting products by sea, there is a high chance that they will come into contact with moisture.Contact with sea water or sea weather conditions may be the cause.The longer your products are on the move, the higher the risk of corrosion.

If products are transported by container, high humidity in the container will be an additional risk factor.Experts therefore advise not to use materials with a moisture content of more than 15%, and to equip your products with quality corrosion protection.1

►autumn and winter

Une saison est plus favorable à la corrosion que l’autre. L’automne et l’hiver sont souvent les plus humides. La pluie et la neige sont alors des dangers pour vos produits, au risque de les rouiller. La rouille blanche en est un exemple précis.

La rouille blanche se marque sur l’acier galvanisé à chaud qui est entré en contact avec l’humidité pendant le transport ou le stockage, et qui est également mal ventilé. À un moment donné, l’humidité commence à se condenser et des taches blanches apparaissent sur l’acier. Bien que cela n’affecte pas la qualité du produit, la rouille blanche nuit à son apparence.²

Formation de corrosion lors du transport outre-mer | La rouille blanche en hiver

Formation de corrosion lors du transport outre-mer | La rouille blanche en hiver

3. How can corrosion be prevented?

Corrosion protection is more important than ever. It all starts with careful storage and transport. There are three types of corrosion protection: VCI packaging, reinforced tar paper/paraffin-coated kraft paper and desiccant bags.

► VCI packaging

VCI

stands

forVolatile Corrosion Inhibitor.It works as follows: in an insulated space (such as a crate), VCI packaging creates an invisible layer on metal surfaces.The VCI layer does not change the properties of the metal, but instead blocks the ability of oxygen and moisture to corrode it.Once unpacked, these metal parts can be used immediately.Cleaning or degreasing is therefore not necessary.3

Below are some examples of popular VCI packaging.A special case is paper with a VCI layer

.

It is generally more economical than plastic versions and is used in the automotive and metal industries, among others.

Plastic zip bag |

Plastic bag |

Plastic film |

| For small products | For medium products | For large products |

| Polyethylene, 100 microns | Polyethylene, 100 microns | Polyethylene, 150 microns |

| Zipper closure = closes at will | Gusseted = more volume | On a roll |

- VCI was developed in 1940 by George Daubert, a service station owner, who mixed an anti-corrosion agent with oils to create a fast and environmentally friendly alternative to traditional greases and oils.

- ICV was first used on a large scale by the US military in 1940 ? the US used it to ship weapons, parts, etc. during World War II.

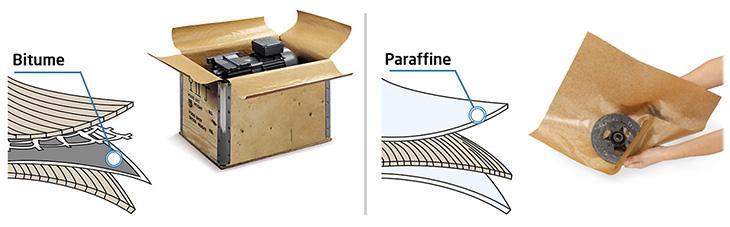

► Armoured tar paper or waxed kraft paper

It’snot just VCI packaging that provides a buffer against corrosion.There are several other solutions.For example, reinforced tar paper (a layer of bitumen reinforced with a polyester mesh covered with 2 sheets of interkraft paper).This paper is used for marine packaging, among other things.This protection can be used as a liner for cardboard and wooden export crates, overpacks and waterproof packaging.

Another example is paper covered with a layer

of

paraffin.This greasy layer prevents water from penetrating the paper and therefore damaging your product.

►desiccant bags

Doyou really want to play it safe? Combine your VCI packaging with a desiccant bag. The desiccant bag absorbs moisture and thus reduces the risk of corrosion. For the most complete corrosion protection possible, the desiccant bag is really essential.

4. How to use VCI anti-corrosion packaging?

When it comes toVCI packaging, it is best to take the following rules into account. This is the only way to ensure optimal performance

- Make sure your metal parts are clean and dry, and also allow them to acclimatise to room temperature before packing (thermal shock can cause condensation).

- There should be no incipient corrosion on your product.

- Wear gloves when handling VCI packaging.

- There should be no direct contact between your metal parts and any materials that promote corrosion (e.g. wood or cardboard).

- Apply the VCI packaging with the printed side facing outwards.

- Close the packaging completely – this is the only way to ensure that it works properly.

- When unpacking your metal parts, they should also be acclimatised to the room temperature again. This prevents condensation from forming again.

- After unpacking, your metal parts are immediately ready for use. The VCI protection does not leave any traces.

su_spacer]

Sources:1 www.praxas.com/nl-nl/Nieuws/Over-Praxas/ID/72/Corrosie-staal-tijdens-transport-en-opslag-hoeft-geen-uitdaging-meer-te-zijn2 www.rotocoat.nl/verzinken/technische-informatie/witte-roest

3 www.cortecvci.com/how-vci-works/