With the 7 tips in this article, you can make your workplace more productive. How do you properly adjust your packing table? How do you move heavy goods correctly? What tools can you incorporate to make order picking easier? In this article, we will answer all these questions, always with the physical well-being of your colleagues in mind.

su_spacer]

Everything for a more productive warehouse layout

► 1. Adjust your packing table correctly

Although this advice is self-evident, we note that many companies still have to prove themselves in terms of improvement. We cannot repeat it enough, a poorly positioned packing table is a source of repeated complaints, such as bending down too often to reach materials, standing in the same position for too long, etc. And this, of course, is detrimental to productivity. So here are a few tips

-

Place all work equipment within a 60° radius of your packing table so that everything is within easy reach.

-

If your packer will be standing for more than 2 hours a day, consider a sit-stand or more traditional shop chair.

-

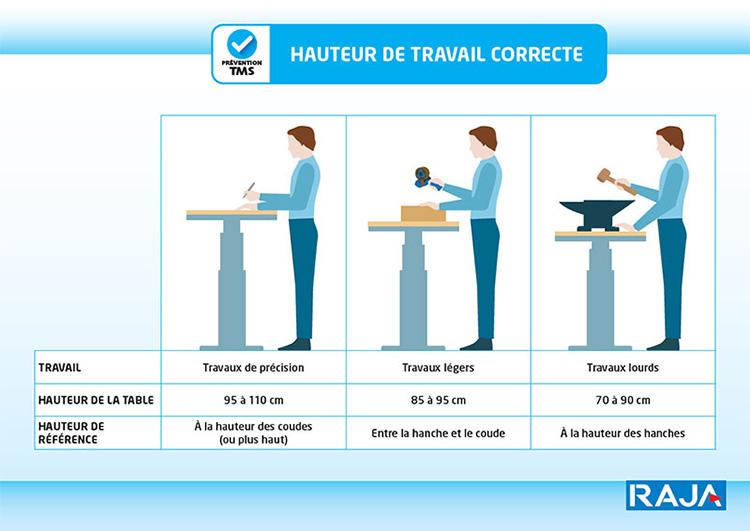

Adjust your packing table to the right height, you can refer to our table below to do this.

► 2. Create a pleasant working environment

Light, sound, temperature… These factors have a bigger impact on our productivity than you might think. Below are some things to consider if you’re in the process of creating a more productive workplace

-

Temperature: too high and everyone will become sluggish and slow; too low and your storekeepers’ muscles and joints will become too stiff and make them suffer. The happy medium? Keep the temperature between 14 and 18 °C.

-

Light intensity: too dark and your storekeepers’ eyes will get tired faster. too bright and your storekeepers will suffer headaches. In a warehouse, it is recommended to have a light intensity between 100 lux (for the aisles) and 300 lux (for the packing station).

-

Sound: Noise can be a very disturbing factor in a workplace, so make sure your warehouse floor is as smooth as possible. This is because your handling equipment (especially if it is filled with loads) will cause a lot of noise if the floor is bumpy. Also, bumps on the floor can cause body shocks for people manoeuvring rolling stock. Which is something we obviously want to avoid.

► 3. Move and lift your goods efficiently

Moving and lifting your goods efficiently is an important factor in creating a more productive warehouse. For heavier or bulkier goods, warehouse workers are advised to use the following tools

-

Choose an electric pallet truck to make it easier for your warehouse workers to move heavy loads. A hop on the back of the pallet truck and off you go! It’s still better than walking for miles. However, make sure that the driver maintains sufficient braking distance, as a sudden stop can be dangerous for the neck or shoulders.

-

Opt for a high-lift pallet truck (or scissor lift) to lift goods up to 80 cm off the ground, so your warehouse workers can work at hip height, which is much better for their backs.

-

To transport and lift loads at the same time, it is best to work with a lift table. By means of the hydraulic foot pedal, the platform lifts and brings the goods to the right height.

► 4. Optimise order picking

After pallet trucks and lift tables for heavy and bulky loads, let’s move on to smaller loads. Let’s face it, a pile of small boxes can sometimes be just as taxing on your warehouse workers. To ensure more productive order picking and storage of small goods, opt for hand trucks or trolleys. Your choice will need to be based on the weight and type of load you need to move. To find out more about this, you can check out our article on rolling stock in a warehouse

-

A skate hand truck is ideal for negotiating stairs and doorways.

-

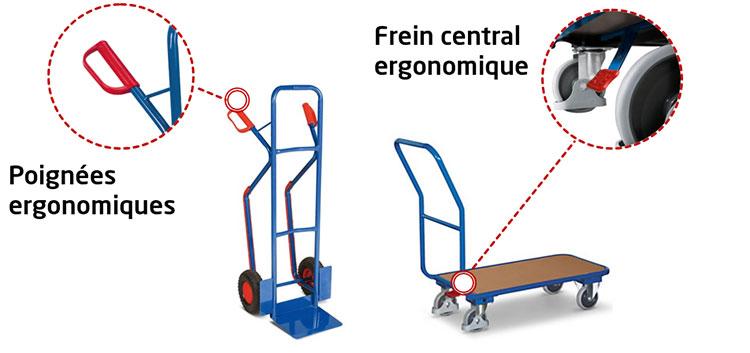

Choose a hand truck or trolley with ergonomic handles to get a better grip.

-

Finally, let’s not forget the trolley with a central brake. Thanks to its brake pedal, the wheels can be blocked easily, without having to bend over (= less strain on the back). In addition, even with large safety shoes, the brake remains easy to use.

► 5. Switch from work to a filming machine

Le banderolage des palettes est l’une des phases les plus importantes dans le processus de préparation de commandes. Pour votre emballeur, il s’agit d’un véritable défi à chaque fois. En effet, le film étirable n’est pas toujours évident à manipuler et souvent, les palettes sont lourdes à déplacer.

Bref, cette tâche ajoute une pression supplémentaire sur les épaules de vos magasiniers. Néanmoins, avec une filmeuse, vous éviterez de nombreux risques de douleur. Cette machine fait presque tout le travail et ce, plus vite et avec plus précision qu’un humain. Téléchargez l’e-book de RAJA et découvrez quelle est la filmeuse idéale pour votre entreprise.

On estime que près de 80 % des entreprises dans le secteur logistique utilisent déjà des banderoleuses, entre autres, pour assurer un politique productif et ergonomique.

► 6. Take the strain out of standing work with an anti-fatigue mat

Your warehousemen and packers stand for most of the time, right? It’s no surprise to you either that working on your feet for long periods of time causes back, knee and ankle pain.

So make your staff’s job easier with an anti-fatigue mat. Fe

aturing

a unique ribbed surface, this mat will keep your packers constantly on the move, as staying on the move when doing monotonous work will make muscle and joint pain appear less quickly.

► 7. Voice picking: combine productivity with technology

Avec la méthode « voice picking », vos emballeurs sont équipés d’un casque audio. Le programme leur dit ensuite vers quel rayonnage ils doivent se diriger, en tenant compte de l’itinéraire le plus optimal.

Le système « voice picking » est relié à un système de gestion d’entrepôt. Le but de ce logiciel est d’optimiser les mouvements dans un entrepôt et de rendre la préparation des commandes beaucoup plus fluide. Grâce au casque, vos magasiniers gardent les mains libres, ce qui réduit considérablement la sollicitation des muscles et des articulations du haut du corps. En outre, le risque d’erreur est également réduit, ce qui nous amène au résultat final : un entrepôt plus productif.