how many times have you dreamed of having a robot that does everything for you? In the world of packaging, this dream is still a pipe dream… but it is on its way to becoming a reality in just a few years. Packaging automation trends tell us about machines capable of packaging faster and more efficiently, reducing material waste and speeding up production times. Have you already thought about taking advantage of this wave of innovation in your company or warehouse?

While it is true that the most groundbreaking proposals in terms of packaging automation still need some time to find their place in the market, there are already packaging solutions and products within your reach with which you can mechanise a large part of the package preparation tasks. Stay with us and find out where the future is going and what industrial procedures you can implement without waiting any longer to save effort, time and money in your business.

Packaging automation trends: what will the future bring?

At the forefront of packaging automation, there are two clear leaders: Amazon and the parcel providers of large US companies.

Amazon tests machines that pack 700 boxes per hour

Amazon has already started testing machines called CartonWrap, capable of packing 600 to 700 boxes per hour in some of its warehouses. They work four to five times faster than an operator and, simply by analysing the size of each product or set of products for a few seconds, they are ready to automatically select the right size wrapper and configure the order.

When the container automatically adapts to the contents

Modern Materials Handling echoes the latest developments in packaging automation to reduce the size of packages and consequently optimise volumetric weight, an unavoidable objective when it has been found that companies are using boxes in their shipments that, on average, are 40% larger than they need to be

Among the mechanisation proposals available in the North American market that MMH highlightsare:

- Technology that assembles made-to-measure boxes in a few seconds, taking on the tasks of cutting, folding, gluing and printing from corrugated cardboard sheets.

- Machines that adapt the height of the boxes by trimming the excess from the top depending on the size of the contents.

- Solutions that modulate the size of shipping bags or create shrink-wrapping based solely on shrink-wrap.

what can you do right now to automate your packaging processes?

Whatever the future holds, what is clear is that you can start making changes to your packaging processes now and become more competitive. Choose RAJA® as your reliable partner for order automation in your warehouse. We can assist you in adopting mechanised solutions for the filling and closing of your packages.

1.solutions to automate the filling of packages

Filled packaging is essential to protect the most fragile and delicate objects during transport. RAJA® has air or paper filling packaging systems for sale or rental that fill empty spaces and cushion shocks

Here are 2 new filling systems for you to choose from:

RAJA Air machine

- For small and medium production rates

- Film made up of 35% potato starch

- Uses less material: 99% air bag once inflated

Protective WrapPak® converter

- Versatile and effective for filling and protecting fragile products

- Insulating, able to avoid temperature changes thanks to its corrugated surface

- High productivity

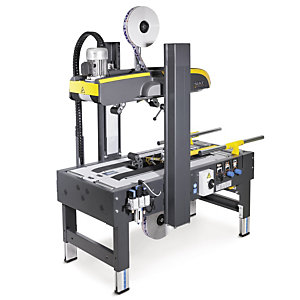

2.machinery to automate the sealing of packages

When it comes to securing your packages, we present you with different packaging automation ideas depending on the type of goods and their size:

- Shrink wrappingmachinesto shrink wrap large volumes such as full pallets.

- Tablestrapping machinesthat adapt to packages of all sizes, regulating the strap tension according to their fragility.

- Box sealing machines that automate the sealing with gummed paper.

Combining automatic package filling systems with machines that speed up the wrapping and closing of packages will increase the ratio of orders per hour that your team is capable of handling. In addition, the automation of packaging will improve the health of your workers, who will remain safe from injuries and ailments derived from repetitive movements. Check out RajaSystem, our catalogue of mechanisation solutions for your warehouse, and partner with RAJA® to optimise the assembly of your packaging!