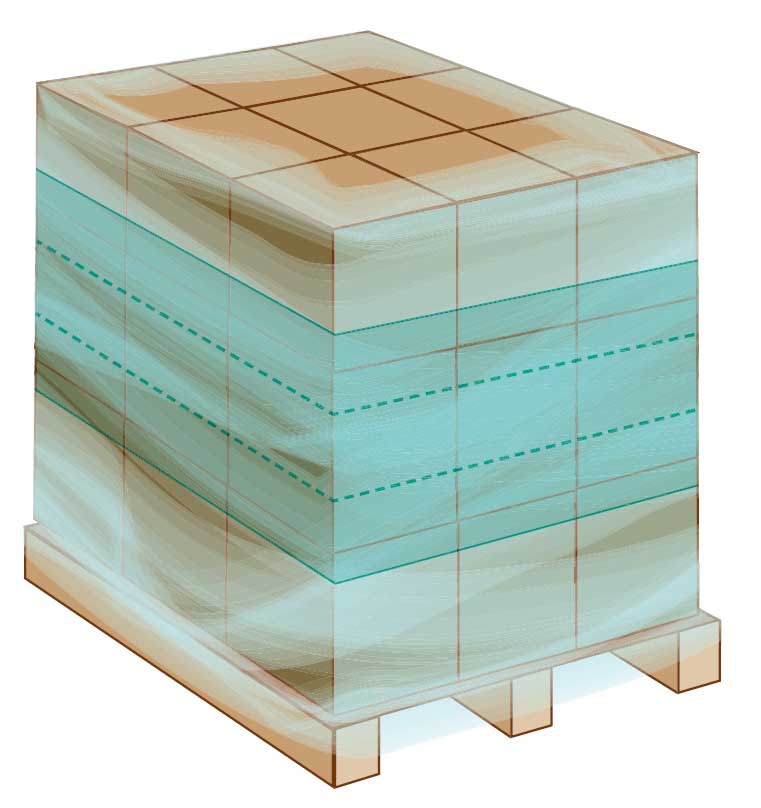

We’ve already discussed stretch film and the benefits of colour film earlier.Now let’s move on to the next step: automation.If you ship more than 15 pallets a day,then you should consider buying a stretch wrapping machine.With this machine,you’ll save a huge amount of time and use a lot less film.You’ll also notice that your pallets are more stable and better packaged.Whether your pallet has to travel a long,bumpy road,face rough seas,or is in the clouds,your goods will reach your customer in perfect condition.Find out more about the best pallet wrapping machines here.

Why choose a banding machine?

[Do you want to wrap your goods using a manual unwinder, or would you rather do it via a stretch wrapper? Each system has its advantages depending on how you want to use it

► Manual unwinders are versatile and suitable for both small and large products, homogeneous and heterogeneous goods, and pallet and non-pallet loads. For companies that only ship a few pallets a day, stretch film unwinders are convenient and inexpensive. These sturdy unwinders come with two handles. Attach the roll of stretch film to the unwinder and get started immediately.

► Manual unwinders are versatile and suitable for both small and large products, homogeneous and heterogeneous goods, and pallet and non-pallet loads. For companies that only ship a few pallets a day, stretch film unwinders are convenient and inexpensive. These sturdy unwinders come with two handles. Attach the roll of stretch film to the unwinder and get started immediately.

► If your company ships more than 15 pallets a day, then the automated solution is a good investment. This way, you will not only take the strain off your warehouse worker’s back, but you will also save a lot of time and film because a wrapping machine it also wraps much faster and better than anyone else could.

| Manual wrapping |

Automated banding |

| Versatility of use – homogeneous or heterogeneous loads,– large or small products,–with or without pallets. | Save film: stretch the film to the maximum and never use more film than necessary. |

| For less than 15 pallets per day | For more than 15 pallets per day. |

| Work ergonomically. | |

| Save time: the machine does all the work for you. |

Which film wrapping machine should I choose?

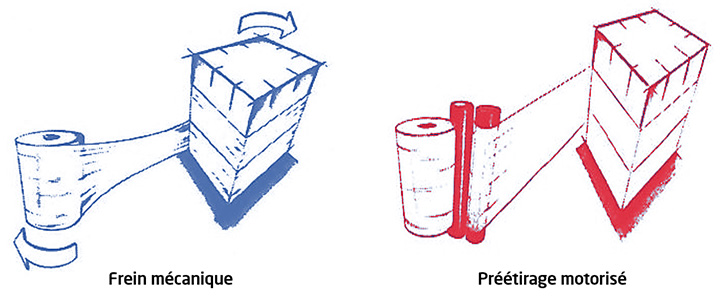

In general, there are two types of spinning machines: one with a mechanical brake system, or one with a motorised pre-stretching system

- System with mechanical brake = those with a braking system are technically the simplest and therefore also the cheapest. The film is stretched with the help of a brake (up to a maximum of 100%). The result is that the film shrinks a little. You will therefore need more film per winding. To avoid this, it is advisable to use pre-stretched film.

- System with motorised pre-stretching = The machine pre-stretches the film optimally – up to 400%. The film rolls between two motorised axes that are placed very close to each other. The result of this process is a film that is no longer shrunk and that covers your pallet as much as possible.

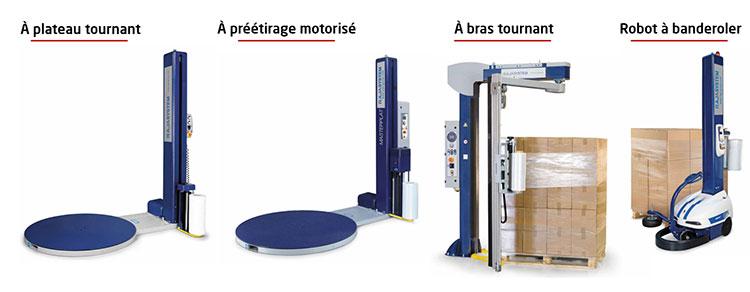

As you can see below, there are several types to choose from:

Type of wrapping machine. |

Number of pallets & Type of load |

Advantages |

| (1) Mobile decoiler | –from 15 pallets per day–regular or irregular shaped loads. | The most advantageous solution. |

| (2) Turntable* | –< max. 50 pallets per day–regular shaped load. | The mechanical brake ensures even packaging. |

| (2) Turntable andmotorised pre-stretching** | –< max. 150 pallets per day–regular or irregular shaped load. | The pre-stretching ensures a max. economyon the amount of film used. |

| (3) Rotating arm* | –< max. 250 pallets per day–unstable loads and goods too heavy for a turntable. | With rotating arm that wraps the film around a very heavy pallet. |

| (4) Banding robot*** | –< max. 250 pallets per day–for loads which, due to their shape or weight, cannot be placed on the platform of a wrapping machine. | Automatically moves.around loads of min. 60 x 60 cm. |

► 1. Mobile unwinder

Let’s start our comparison with the mobile unwinder.This is the cheapest solution, which still requires a little effort.The storekeeper has to turn around the pallet himself.

The film is then applied with constant tension and holds the load perfectly in place, without any damage.The mobile unwinder

is

adjustable in height,

which

allows you to work with rolls of stretch film of different widths.

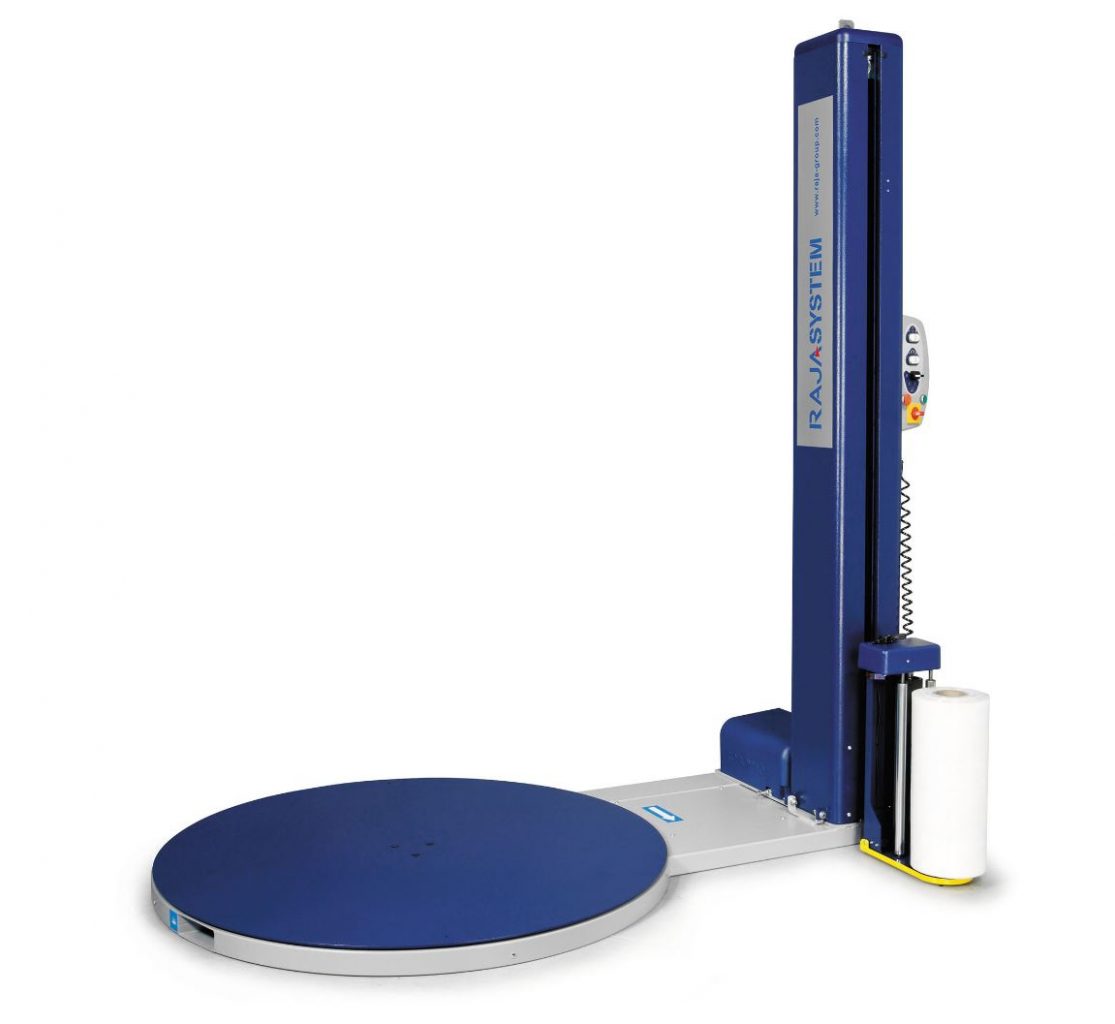

► 2. Spinner with turntable (+ motorised pre-drawing)

Les banderoleuses à plateau tournant sont généralement utilisées pour des palettes standard (jusqu’à 2000 kg), pourvues d’une charge homogène. Vous placez une palette sur le plateau tournant, attachez le film au bas de la palette, appuyez sur le bouton de démarrage et le plateau tournant tourne sur son propre axe. De cette façon, le film est enroulé autour de la palette avec une tension constante : sûr et précis.

Avec le modèle à préétirage motorisé, vous pouvez emballer également des charges hétérogènes ou des produits sensibles à l’écrasement. Le système de préétirage motorisé étire le film jusqu’à 300 %. Cela permet d’utiliser encore mieux votre quantité de film et donc d’économisez considérablement sur votre consommation totale.

► 3. Rotating arm spinning machine

La filmeuse à bras tournant filme beaucoup plus rapidement que la filmeuse à plateau tournant. Votre charge reste immobile et n’est pas affectée par la force de rotation du plateau. C’est aussi une solution idéale pour envelopper des charges très lourdes (de plus de 2000 kg). Ceux-ci ne peuvent pas toujours être placés sur un plateau tournant.

Cette filmeuse est synonyme de sécurité d’utilisation: le bras tournant est équipé d’une mousse absorbant les chocs. Il s’arrête immédiatement sur un obstacle ou lorsque vous appuyez sur le bouton d’arrêt d’urgence. De plus, il est ergonomique: le support du film s’arrête toujours à la bonne hauteur afin que votre magasinier puisse facilement remplacer le rouleau.

► 4. Wrapping robot

A wrapping robot is a multifunctional device that is easy to move and wraps pallets fully automatically. Regular and irregular shapes with protruding parts: this device can wrap anything.This wrapping machine itself rotates around the pallet and maintains a constant force on the film.You also save a lot of space: once the wrapping is finished, you can store it safely outside the working area of your warehouse.

The model with a motorised pre-stretching system also saves you a lot of money on your stretch film.If you are using a stretch film with an elasticity of 250%, for example, 1 metre of film can be stretched up to 3.5 metres.