The next Metapak study could send a chill down the spine of many e-tailers: same day delivery will soon become standard for a majority of consumers. This was already the case for 31% of them in 2016 ; while the most economical delivery methods lost 7% of market share (delivery in parcel relays, reception at the post office). More than ever the adage time is money is proving to be true. How can you organise yourself in order to satisfy customers who want to receive their parcels more and more quickly? We offer you a few pieces of advice in this synthetic article.

The choice of your packaging as much as the equipment at the disposal of the preparation teams in the warehouse contribute to the speed of execution

Contents

- Reduce case formation by a factor of 3

- Reduce or eliminate wedging

- Pack faster

- Close your crates faster

- Save your warehouse staff for the long term

- Secure the warehouse

- Mechanise order picking and palletising

#1 – Divide by 3 the shaping of your case thanks to automatic bottom boxes

illustrated in video with brilliance by our Italian team(forza RAJAPACK Italia!), you will understand the double interest of the crate: significant improvement of the preparation; reduction of the tediousness of the teams which will form tens of crates in the day

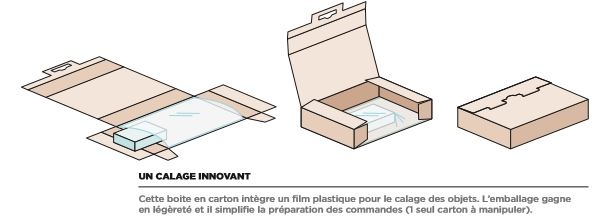

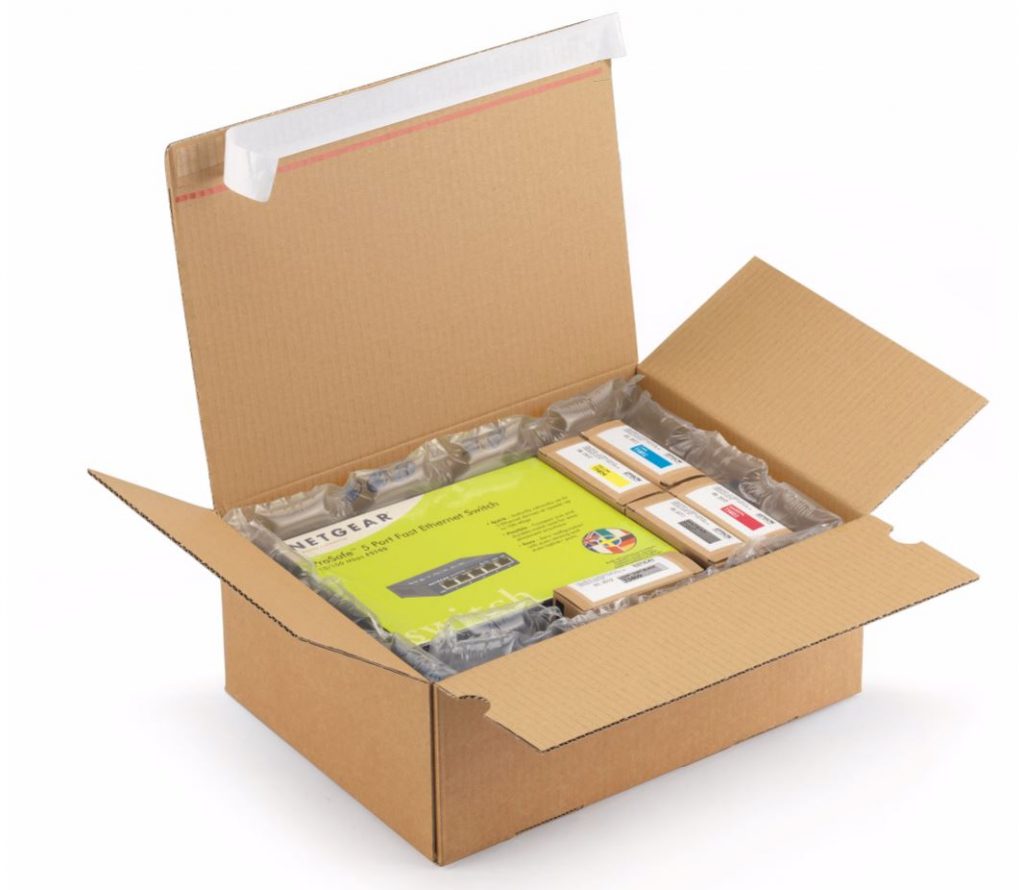

#2 – Reduce or eliminate wedging with custom packaging and Korrvu®

the packing step can be reduced or eliminated if you opt for a custom-made packaging according to the specific dimensions of your goods.

Cheerz has chosen custom-made packaging for the shipment of its boxes and photo albums of standardised dimensions in order to reduce the packing, the preparation time and the overall weight/volume of the product.

The Korrvu® boxes and cases are ready to use thanks to their integrated film

note: Eliminating the cushioning has the added benefit of reducing the learning curve for any new employee or temporary worker in the warehouse. Also, don’t hesitate to design an optimal packing station for your teams, a real anti-TMS tool and a guarantee of productivity.

#3 – Optimise the time needed for wedging

the various dimensions of your goods may not allow you to opt for customised packaging, so dunnage is necessary to fill the void in standard-sized crates. However, there are solutions to reduce the operation for your order pickers. Mechanisation allows you to provide operators with dunnage that is easy to arrange. Paper dunnage or air cushions are the quickest: you simply fill in the space between the goods and the top of the crate. Paper dunnage is the choice of many e-tailers: from Amazon to Greenweez. It is also the choice of the RAJA logistics team

on this video clip: it is clear that paper wedging is faster than using wedge particles.By rationalising the number of references

- You facilitate storage management

- You simplify the work of the preparers who manage a limited choice of packaging at the preparation stage

- You massively purchase the remaining references allowing you to renegotiate your prices

- You may improve your company’s CSR performance by opting for recyclable packaging.

#4 – Speed up case closing

we invite you to contact one of our experts by phone or request a visit for a quick and complete audit. However, here are some simple solutions that are easy to implement:

Cases with integrated adhesive tape are obviously one solution. But choosing a premium dispenser is another! I was able to see this again a few weeks ago during a visit to a major player in online parapharmacy

- The lighter, more manageable reel allows you to be more precise and reduce errors.

- And de facto spare the hard-working elbow of the pickers.

and if you handle more than 200 cases a day, a case closing machine should be considered. It will allow you to detach an operator from this task. You will optimise working time and at the same time control the wage bill in the warehouse

#5 – Save the teams

parce que cette course de vitesse est une course de fond et pas un sprint, pensez à améliorer le quotidien des équipes.

En sus des conseils concernant la mécanisation du calage qui va réduire l’effort apporter à chaque préparation ou le choix d’un adhésif silencieux qui apporte un confort sonore évident aux équipes. C’est l’ergonomie du poste de travail qui fera la différence.

La hauteur adaptée des tables de travail, la mise à disposition immédiate des emballages les plus utilisés, des sièges assis – debout et les tapis anti-fatigue sont autant d’éléments qui vont ménager l’énergie des préparateurs et réduire les TMS.

Rappelons que les Troubles Musculo-Squelettiques sont la première cause d’absentéisme dans l’entrepôt.

Trouver un remplaçant et le former nuira plus fortement à la productivité et au retour sur investissement global de l’entreprise que l’ensemble des investissements effectués pour réduire la pénibilité au travail. D’autant plus que vous bé

#6 – Secure the area

because in a fast-paced warehouse, strict safety rules must be put in place.Signs, barriers, gloves, helmets and other personal protective equipment are necessary

#7 If you ship pallets, the stretch wrapper is your ally

three major advantages of these machines

- Speed of execution compared to the order picker

- Reduction of the workload because palletising is the source of a large number of RSI in the warehouse (to the point of being subject to a specific aid: the AFS Filmeuse+)

- Masked time work which leaves the picker free to do another task in parallel

we invite you to take a look at our RAJA mini-guide to choosing a wrapping machine (5 min is all it takes), which details the respective advantages of turntable wrapping machines, rotating arm wrapping machines and wrapping robots