The definition of storage is based on the idea of intelligent placement of stocks, in order to find the products you are looking for as quickly as possible. Discover a series of tips for the layout and smooth running of your warehouse, thanks to adapted storage shelving.Also known as warehousing, relevant storage guarantees the proper preservation of goods, safety, employee circulation and optimisation of space. But it also includes the idea of good stock management in order to avoid stock-outs or over-storage.This article was last updated in December 2020

the objectives of the logistics manager

As the guarantor of the smooth running of the goods/shipment area, the logistics manager must ensure that the logistics chain is never broken due to stock shortages, work stoppages, missing links, etc.Good stock management and warehousing are therefore at the heart of his or her concerns.

1 – Identify the products to be stored

The first step before choosing a storage method may seem basic, but is nevertheless essential: take an inventory of your goods before expanding the storage space!By sorting out the inventory, you may realise that you tend to over-stock the number of your cartons, for example. Ask yourself

- What is the number of products to be sent per day?

- What are the packaging material requirements for your shipments?

you will then be able to establish your storage material needs precisely and evaluate permanent shortages versus items in excess.

Storage optimisation tip

Take advantage of the beginning of the year to clear out your products! Save space, save money, and above all create a new basis for a good start to the new year. Clearing out the space allows you to reorganise the spaces for better storage optimisation.

2 – Analyse the environment to optimise movements

Draw up a map of your storage, packaging and dispatch areas: a storage rack installed in the right geographical location will limit unnecessary and laborious movements. The storage spaces must be structured and ordered to facilitate the task of the order pickers. To do this, several options are available to you

- Set up shelving;

- Delimit the warehouse areas;

- Delimit overstock areas;

- Delimit the packaging areas (e.g. by ensuring that the cushioning products are close by).

the most common method is to number each industrial shelf, then each shelf, then each compartment.

3 – Determine the layout

Once you have drawn up the best logistical map, look at the existing installations: be careful not to obstruct emergency exits or access to certain areas,for example .Also remember not to install your shelving against fixed and immovable elements such as pipes. Revise your storage plan according to the latter elements.

4 – Facilitate circulation and handling

Once the storage spaces have been established, think about determining the necessary width between the spaces

- Trolleys must be able to pass between the shelves;

- Products must remain accessible.

5 – Vérifier la nature du sol

Un sol en béton assure par exemple la bonne stabilité du rayonnage. Si votre sol semble plus fragile, sa planéité doit être vérifiée.

Si votre sol est instable mais que vous n’avez pas l’intention d’effectuer des travaux pour l’aplanir ou le rigidifier, vous pouvez utiliser des outils comme des cales de mise à niveau ou des pieds ajustables.

Évitez cependant les rayonnages lourds en cas d’instabilité des sols et optez plutôt pour du mi-lourd.

6 – Choisir son modèle de rayonnage de stockage

Selon vos besoins de stockage et les produits à entreposer, les rayonnages peuvent prendre différentes formes. Aussi appelés « racks de stockage », ce type de rayonnages se compose de plusieurs étagères métalliques capables de supporter des charges plus ou moins lourdes.

On peut trouver différents supports adaptés au type de rayonnage et de stockage.

Les différents types de rayonnage

Le rayonnage en acier galvanisé : il ne roui

- The chipboard tray: very robust with large storage dimensions, this is a heavy type of racking;

- The pallet rack: with a height of 3 m, this metal support is specially designed for the storage of pallets;

- Epoxy steel shelving: ideal for light storage such as archives, files, etc.

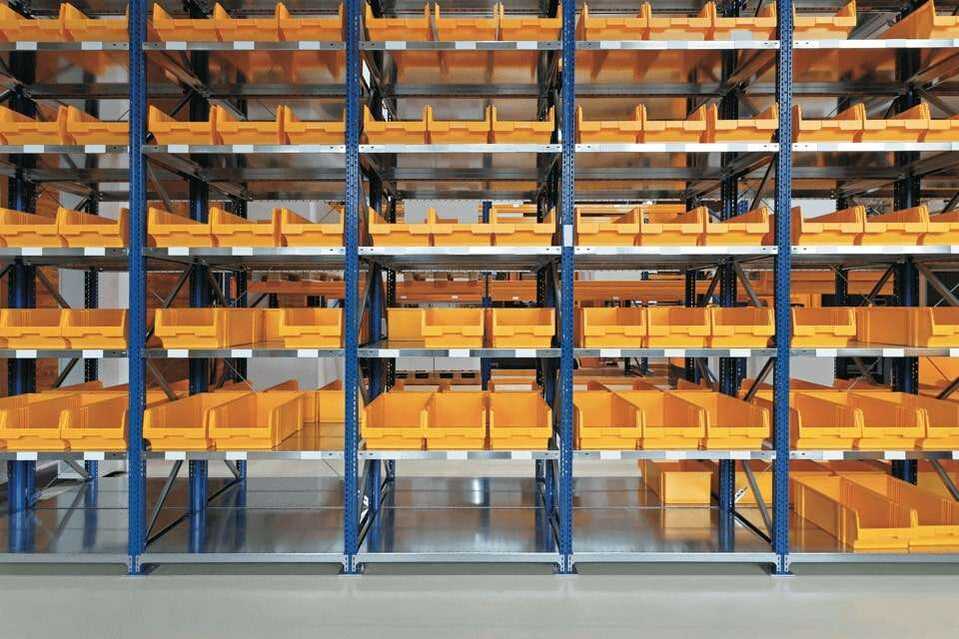

shelving is often modular and can be easily expanded. Similarly, adjustable metal shelves allow the use of shelving to be managed on a mobile basis. Shelving can be composed of

- Shelves: for archives, files, boxes, etc

- Arms: for long elements, such as tubes;

- Angles: to adjust the shelves;

- Side rails: to reinforce the frame of the structure and support heavy loads.

the elements plus storage accessories such as bins, drawers, transparent boxes, etc.

The different storage systems

For manual handling with low rotation, such as archives

- Storage on shelves in aisles;

- Storage on manual and handwheel mobile shelving;

- Mass storage on pallets.

for manual handling with high turnover, such as picking

- Aisle racking storage;

- Dynamic storage on rails (assembly on station);

- Level storage on aisles;

- Level storage on single level;

- Mezzanine level storage.

for mechanical handling with machines

- Storage on pallets with extensions, ideal for products with a high seasonality;

- Aisle rack storage;

- High bay storage, for narrow aisles;

- LIFO or FIFO storage, often used for drinks;

- Mobile base storage: one of the most expensive storage solutions, suitable for cold stores

storage is a key element in the operation of a warehouse and must therefore be considered according to the needs of each company. Choosing the right shelving models is therefore an aspect that should not be neglected in the management of a warehouse’s stock

| RAJA’s extra tip: Once you have chosen your storage racks, don’t forget to get the right handling equipment for your warehouse: ladders, trolleys and pallet trucks can be crucial in helping your staff to manage the warehouse on a daily basis. |

Conclusion: three key points to remember

- Sorting your stock annually during the sales period is a good way to clear the shelves of old products and save valuable space.

- Map out your warehouse, aisles, picking and packing areas so you know where to place your shelving to make the traffic of carts and employees as smooth as possible.

- Choose shelving models adapted to your goods (heavy, semi-heavy, light) while taking into account the nature of your floors.