High-speed logistics warehouses face very specific challenges.

Between the management of large teams, the monitoring of a stock containing many goods (and sometimes many references), and the intense handling that all this requires, there is no shortage of challenges!

In this context, many logistics managers are looking for solutions to further boost the productivity of their packaging line, whether it be packaging, cushioning or palletising solutions.

If this sounds like you, this article will show you how you can speed up your warehouse packaging process without endangering the health of your operators.

The essentials for high-speed packaging

Find out here which packaging methods to choose to ensure optimum productivity on your high-speed packaging line.

Time-saving packaging

Did you know that some packaging allows you to significantly accelerate the speed of your order preparation line, without cutting back on the protection of your goods, even the most fragile?

Take a look at these types of packaging:

|

With these cardboardboxes, your operators only have to press on the sides to automatically lock the bottom of the packaging, which is a real plus and means they don’t need to use adhesive to secure the bottom of the box! |

|

Side-seal boxes: Designed to be shaped in a matter of seconds, these boxes provide optimum protection for your products without burdening your order-picking processes. |

|

Do your operators waste time preparing andintegrating cushioning materials into your goods packaging? Take stock of your product protection needs and choose the right ones for cushioned packaging. |

If you want to go one step further and speed up your warehouse, choose packaging with an adhesive sealing strip, which eliminates the need for adhesive tape in your order picking chain.

Case sealing machines

What if technology allowed you to improve the productivity of your packaging line? This is what is promised by case sealing machines which, once set up according to your needs, automate the sealing of your packages.

The principle is simple: your operators place the open packages on the machine, which then seals the top and bottom of the packages with adhesive tape in a very aesthetic manner. They are also designed to be ergonomic, as they can be adjusted in height, and therefore minimise the effort of the operators during order picking.

However, be careful to choose your machine according to the type of parcels you prepare on a daily basis. You have the choice between..

- The single-format case sealing machine, which requires the operator to manually adjust the machine to the size of the parcel using a crank system.

- The multi-format case sealing machine, with automatic adjustment, which offers optimal case guidance.

Thermo-foilers

If your order picking process includes wrapping or bundling products, your packaging line may benefit from the use of a thermofilm machine. This packaging machine seals and shrinks plastic film around the products to protect them or bundle them.

So how do you choose the right heat seal machine for your business?

- For speeds of up to 600 film cycles per hour, choose an automatic ejector heatsealer: this has a motorised conveyor that automatically ejects the product once it has been filmed.

- For speeds up to 700 cycles per hour, choose a tunnel heat sealer, which automatically transfers the product to the film shrink tunnel.

Sealing machines

If your operators pack your goods in bags or pouches, they probably waste a lot of time sealing these packages by hand.

What if you could help them to be more productive, without increasing their workload, by equipping their order-picking station with semi-automatic or industrial sealers?

|

The semi-automatic sealertriggers automated sealing cycles: the operator only has to lower the machine arm for the seal to operate automatically. |

|

Industrial welders are specifically designed for intensive use, and can be semi-automatic or fully automatic. In the latter case, a simple push on the machine’s electric pedal triggers the lowering of the arm and the welding cycle, and the arm is raised automatically at the end of the welding process. This leaves the operator’s arms free to prepare for the next welding operation at the same time! |

The keys to wedging your packages at high speed

Whether it’s to secure products in their packaging or to protect fragile objects in your stock, you can’t do without a suitable wedging method. Get wedging machines specifically dedicated to high speeds, and speed up this stage of order preparation in your warehouse.

Paper wedging machines

Paper cushioning is one of the current packaging trends, as it gives your parcels an eco-friendly image, and can protect as well as traditional bubble wrap.

To help you speed up your cushioning process, choose from the following paper cushioning machines:

|

For up to 500 parcels per day: the Geami electric system creates honeycomb paper, which is aesthetically pleasing and ideal for wrapping |

|

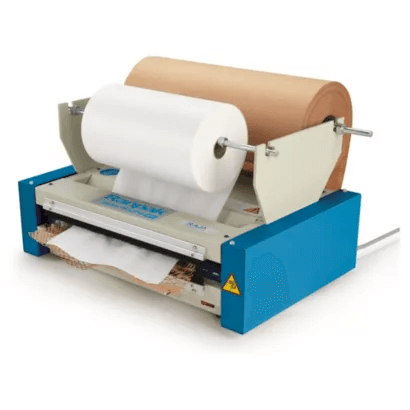

For an output of 1000 to 1500 parcels per day: the WrapPak Protector machine creates paper for wrapping products, in the form of ready-to-use corrugated paper cushions. |

|

For 1000 parcels per day: the FillPak TT machine automatically creates single-fold kraft paper, allowing you to fill the void in your parcels. |

|

For 1000 to 1500 parcels per day: the PadPak Compact machine creates padded paper with a high level of shock absorption. |

|

For a production rate of 1,000 to 1,500 packages per day: the PadPak Senior machine produces paper suitable for cushioning heavy or very bulky products. |

|

For 1,000 to 1,500 parcels per day: the PadPak LC2 machine creates accordion-shaped cushioning for light to medium cushioning, allowing you to fill the void or block the parcels in the cartons. |

|

For a production rate of 1000 to 1500 packages per day: the Guardian machine creates one or two-ply paper cushioning, depending on your protection needs, to cushion light or heavy products. |

Air cushioning machines

If you prefer to use air cushioning in your packaging line, because of the lightness and transparency of this type of material, you can use pre-formed air cushions (thanks to dispenser boxes), but you can also automate the process of inflating the sheaths of your cushioning, thanks to the following machines:

|

For an output of up to 300 packages per day: the RAJA Air 1machine produces up to 10 m/minute of cushioning in the form of cushions, cushion sheets or large air bubbles. |

|

For an output of 500 to 1500 packages per day: the RAJA Air 2 machine produces up to 20 m/minute of cushioning, also in the form of air cushions, air sheets or large bubbles. |

|

For an output of 100 to 2000 packages per day: the Airpouch machine produces air cushions or honeycomb bubbles for vacuum filling, topping or protecting your products. |

|

For an output of 500 to 2000 packages per day: the Fill-Air Rocket machine produces air cushions specifically designed for vacuum filling, at a rate of 30m/minute of cushioning. |

|

For a production rate of 500 to 2000 parcels per day: the NewAir I.B. Flex machine: produces 30 m / min of bubble film, offering maximum security for your products during transport. |

Foam wrapping machines

Want to automate the process of creating your foam padding? The Instapacker™ machine ‘s 10 pre-programmed programs create the padding you need, with foam quality adjustable to the size, shape and weight of your products. The machine is suitable for speeds of up to 500 parcels per day, and produces up to 10 bags per minute.

The essentials for high-speed palletising

Palletising is one of the most time-consuming packaging processes. Fortunately, there are machines that allow you to wrap your pallets faster and band them properly, saving time and ergonomics for your operators.

Stretch wrappers

If you are palletising 10 to 12 pallets a day, it is recommended that you install a stretch wrapper (also known as a stretch wrapper), which not only speeds up your packing rate, but also reduces the risk of Musculoskeletal Disorders in the warehouse.

If every wrapping machine installation project requires a precise study of the packaging conditions in your warehouse, you can choose..

|

A turntable wrapper, if you are wrapping regular, non-fragile loads on standard size pallets, which takes up a significant amount of floor space and therefore needs a dedicated area in the warehouse. |

|

A rotary arm wrapper, which is more suitable for palletising very light or crushable products and must be fixed to the floor, but takes up less space than the turntable wrapper. |

|

A wrapping robot, ideal for filming pallets with an irregular profile. Its great advantage is that it can film anywhere in the warehouse. |

Strapping machines

If you need to strap pallets more efficiently, consider buying or renting a strapping machine, which can partially or fully automate this crucial task for the protection of your products.

|

For strapping up to 50 pallets per day, opt for a semi-automatic strapping machine: the strap is still tensioned manually, but the welding and cutting of the strap is automated. |

|

If you want to strap up to 100 pallets per day, choose the fully automatic version of this machine, which fully automates the tensioning, welding and cutting of the strap, for optimum ergonomics and significant time savings. |

Good to know: these machines also exist for the strapping of parcels (from 50 to 100 parcels per day), so that your operators do not need to use manual strapping machines.

You are now ready to accelerate your high packaging rate even more, while improving the working conditions of your operators!