Stackable bins are storage boxes that save space because, as their name suggests, they can be stacked. They can hold everything from tools to small parts. You can rely on them for easy, safe transport of goods and order preparation. But not all bins are created equal, which is why it’s a good idea to look for those that are perfectly suited to your business. So how do you go about it? That’s what we explain in this article.

1. What types of stacking bins are there?

Stacking bins come in a multitude of shapes and colours. This is of course useful if you’re looking for a very specific one, but as they say, too much choice kills the choice. That’s why we’ve listed the different types of stacking bins below. They can be accompanied by useful accessories to make the most of logistics operations.

► Stackable bin guide

Choosing a stackable bin depends on many factors: what you want to store in it, the space you have available, the need to transport the contents… To make things easier for you, we’ve summarised the different types of stackable bin below, along with their properties and areas of application. So you can compare the advantages and make the best choice.

| Type | Features | Applications |

European standard stackable bin |

|

European standard stacking bins are ideal for Euro pallets (1200 x 800 mm), industrial pallets (1200 x 1000 mm) and warehouse rolls (800 x 600 mm). |

Stack and nest bins |

|

Save up to 70-75% space by nesting empty bins inside each other. Can be used during storage and transport. |

Front-opening stackable bin |

|

Front opening makes it easy to identify, deposit and retrieve items contained in the bin. |

Storage bin |

|

Protects products from external factors such as dust, moisture and light. Very easy to move. |

Coloured stacking bin |

|

Allows you to design an internal colour system to arrange products quickly, logically and conveniently. |

Transparent stacking bin |

|

The transparent walls make the contents immediately visible. Very practical for finding an item immediately. |

Open-work stacking bin |

|

Do you store fresh produce or items that need to dry quickly? Perforations guarantee better preservation of their quality. |

Front-opening stackable cardboard bin |

|

The eco-labelled alternative to plastic bins. |

► Combine your stacking bin with practical accessories

Organising storage with stackable bins is a good start, but it doesn't stop there. There are all sorts of accessories to help you be even more efficient. Improve the quality of your storage with these practical accessories.

Safety seals |

For added security, seal the lids of stacking bins. A nestable stacker with a sealed lid offers optimum protection for goods and reduces the risk of theft or loss.

Combine the buffers (left) with this stack and nest bin. |

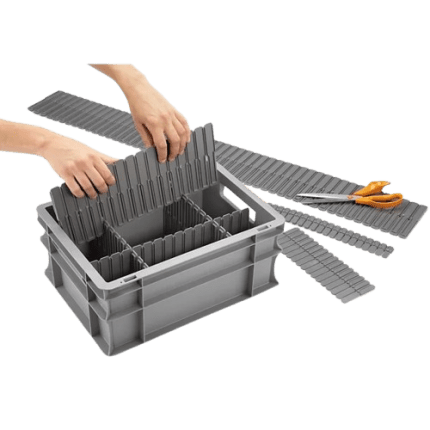

Split divider |

To store small items separately and easily, add practical compartments inside the stackable bin. The notches allow you to cut them out effortlessly and create a bin to suit your items.

Suitable for all Euronorm stacking bins |

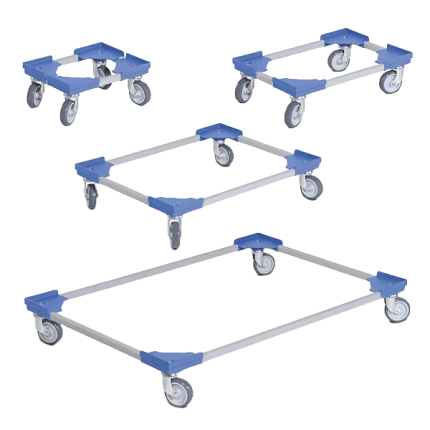

Trolley for bins and pallets |

Trolleys make it easy to move one or more stackable bins. Choose a trolley adapted to Euronorm bins or a simple rolling tray for other formats. |

Label holders |

Easily label all the contents of stacking bins with a self-adhesive label holder. This way, you won't waste a second looking for the item you need. When the contents change, simply replace the label. |

2. Four tips for efficient storage with stacking bins

Now that you know what types of stacking bins exist and what the main differences are, all that's left for you to do is make the most of your new purchase. To get you started, we've put together some practical tips on how to organise storage with stackable bins.

► Choose the right material for your working environment

The type of content and storage conditions determine the most appropriate material:

- Plastic: stackable packaging in polyethylene (PE) or polypropylene (PP) is lightweight, easy to clean and cost-effective. They come in a wide range of sizes and colours.

- Cardboard: lightweight and recyclable, cardboard absorbs noise, making it ideal for conveyor belts.

- Metal and stainless steel: these bins are very strong and resistant, making them suitable for storing heavy loads.

► Organising, labelling and sorting with the stacking bin

By classifying materials intelligently, you increase efficiency and, consequently, your results. To find any item quickly, you can sort according to different criteria:

- Content: group similar items together.

- Frequency: place the most frequently used items in easily accessible locations.

- Transportability: take into account the weight and size of items when choosing their location.

Once you've sorted your equipment, it's also important to make sure that everyone can find it easily. So set up a structured system using coloured bins and clear labels for quick and accurate identification. Partitions allow you to easily separate content from your grouped content.

► Think about storage and transport of the stackable bin

A stackable bin isn't just meant to be stored in one place; it can also be used to transport materials. Rarely or regularly. In this case, it is very important to take into account the load capacity, which varies according to the application.

Static load This is the maximum weight that a stackable bin can support when it is not in motion, for example on a warehouse shelf. The static load force is generally higher than the dynamic load force.

Dynamic load This is the maximum weight a stackable bin can support during transport or movement. The dynamic load force is generally 30-50% lower than the static load force, due to the greater likelihood of load peaks during movement.

► Optimising the available surface area

When you have limited space to store tools and products, it's best to organise storage vertically. Stacking bins are a preferred means of doing this. This way, you can store more material in less space, which even makes warehouse maintenance easier. What's more, for added flexibility, you can even make them mobile by using a chassis with castors. There are also many warehouse picking systems, so it's up to you to choose the best one.