When working in a warehouse, palletising loads is an essential task and a logistical challenge. Therefore, it is not only the preparation of the pallet that must be considered, but also its reception, as incorrect palletisation can damage the goods or destabilise the packages. To face this challenge, here are five tips that will help you to carry out a palletisation plan that guarantees the optimal shipment of any type of goods.

What is a palletisation plan?

The palletisation plan is a work scheme that allows you to organise the packages on the pallet with two main objectives:

- Optimising the pallet load. Stacking the maximum number of packages and guaranteeing their protection.

- To achieve easy handling. Stability will make working with the goods safe.

How to palletise the load correctly in 5 steps

According to this palletisation plan, stacking the packages on the pallet is not a matter of chance: it is subject to the respect of a series of good practices that we summarise in these five tips.

1. Pay attention to the load to be palletised

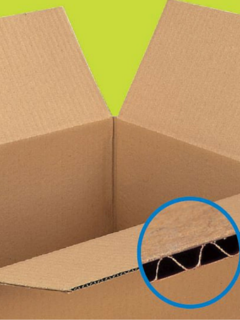

Before you start looking for a pallet and begin to place some packages on top of others, it is essential that you take into account the contents to be palletised. In the event that the load is cardboard boxes, it is advisable to opt for palletisable boxesbecause their dimensions are adapted to the size of the pallets. Palletisable boxes can be single, double or triple channel. Choosing one type of channel or another depends on the weight of the products they contain. Measure and weigh with each package. As a starting point, this information will help you to organise all the goods more accurately and to know if the maximum pallet load is respected.

2. Choose a suitable pallet

Look for a pallet that fits the packages you have to place and that does not exceed its maximum load. To do this, think about which pallet material is more resistant depending on the contents. In addition to the classic wooden pallet, you can also find cardboard, wood fibre or plastic pallets.

3. Place the packages in a logical order

Place the heaviest items at the bottom. If the boxes have different formats, it is advisable to start with the smallest ones. A greater number of angles at the base will ensure the cohesion of the load. When placing boxes on top of each other, you can stack them on top of each other or you can interlock them like a brick wall, the latter method will give more stability to the whole, and between rows of boxes, inserting a plate will distribute the load more evenly. If you are wondering how many rows of boxes you can stack on top of each other, the maximum recommended height should not exceed 1.90 metres.

4. Wrap the contents with film

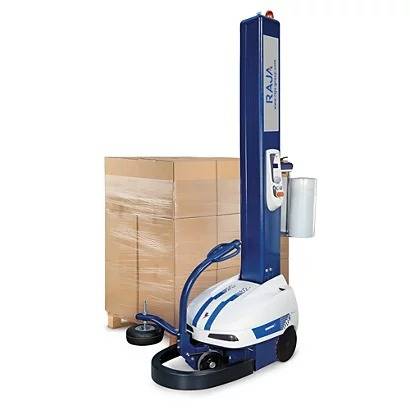

Once the boxes are placed on the pallet, you can protect the corners with corner protectors or other protective elements before covering all the elements with film.

In cases where the number of pallets to be wrapped is small, it is sufficient to use stretch film and manual pre-stretching; however, if the rate of shipment of orders is high, a pallet wrapping machine pallet wrapping machine will make your work easier due to its many advantages: it will speed up preparation and minimise the risk of musculoskeletal disorders (MSDs) in the warehouse.

5. Secure your pallets with strapping

Finally, you can give the contents of the pallet more protection by using strapping. If you don’t know which type of strapping to choose, you should consider its material: it can be made of paper, polypropylene, polyester or thread-by-thread textile.

If you still have any doubts, in this video you will find a summary of the most important steps for efficient palletising and which elements you should take into account:

Palletising the load following this series of instructions will not only ensure that the goods arrive in the best condition, it will also make the process of dismantling the pallet easier and more convenient for the receiver. In addition, with RAJA® you can be sure that the products used to organise your pallet shipments are robust and of the highest quality.