How can we all use plastic packaging sustainably? In recent years, we have seen a clear shift in the way companies use this material. Admittedly, we as a company and as consumers look at it much more critically than, say, 10 years ago. However, plastic still offers many advantages as a packaging material: it is strong, flexible or rigid and can be easily adapted to all types of products – and at a very low cost.

Can plastic really be sustainable for our planet? And which plastics are preferable? Read on below and find out.

1. Plastic packaging is essential for some products

Is plastic packaging really useful? For some companies and sectors, the answer is a resounding yes! In many cases, it is the only material that can perfectly protect your product during storage or transport. Plastic has barrier properties that are still needed in certain sectors in the absence of a good alternative. Just think of their resistance to moisture, oil or air. Some concrete examples are:

- Food sector = plastic packaging is used to preserve food. This way, our food lasts longer and we reduce food waste.

- The pharmaceutical industry = plastic is needed to isolate chemical or cosmetic products or samples for biological analysis.

- The transport industry = for products sensitive to corrosion or moisture, plastic is the most insulating material.

- When transporting hazardous products, a plastic LDPE bag is needed to isolate the goods from the outer packaging (such as wood or cardboard).

2. Plastics should not always be made from petroleum

When we think of plastics, we often automatically think of the raw material ‘petroleum’. But did you know that some plastics can also be made from other materials? Plants, for example? Innovations in the packaging sector in recent years have meant that you can choose from a whole range of these eco-friendly plastics, also known as ‘bioplastics’.

Plastic packaging is usually made from naphtha, a distillate of crude oil? The same raw material is also used to produce fertilisers, perfumes and even medicines.1

Various natural substances can form the basis of a bioplastic. These can include starch (from maize, potatoes, rice or cassava), sugar cane, cotton cellulose, polylactic acid (PLA), etc. A well-known example is the padding chips Flo-pak Natural, made entirely of vegetable starch. After contact with water, they break down, leaving no residual waste. The big advantage of bioplastics is that the plants they are made from filter CO2 from the air during their growth process. Via such a bioplastic, CO2 can therefore be neutralised efficiently.

If you want to recycle bioplastics, you have to be careful…. In a number of cases, these plastics cannot be disposed of with biodegradable waste or in a pmd bag. If you do, they can interfere with the recycling process. It is therefore best to sort these materials with your residual waste. It is good to know that incinerating bioplastics in residual waste is less impactful than incinerating petrochemical plastics.

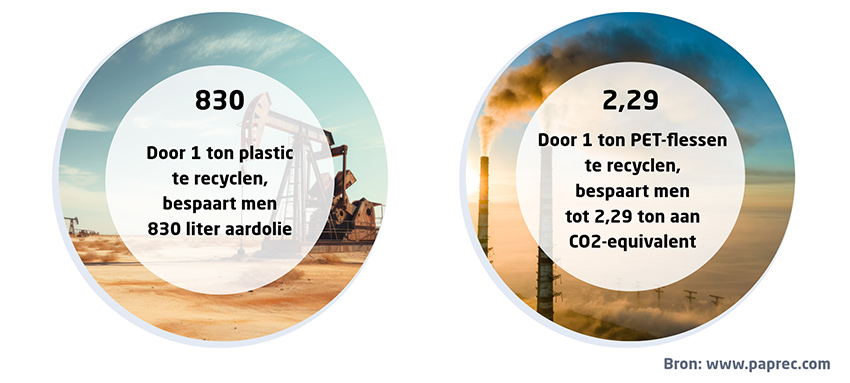

3. Plastic packaging is also recyclable

A lot of plastics are perfectly recyclable (through the right recycling channels, admittedly). They can then be reprocessed into new materials. This way, the raw material cycle is closed and there is much less need for new oil.

We also see that the EU attaches great importance to plastic recycling. Among other things, this is reflected in the new PPWR legislation (Packaging and Packaging Waste Regulation). According to those new rules (which, by the way, are still in the making), from 1 January 2030 plastic packaging would have to contain a minimum amount of recycled material. Otherwise, it may not be placed on the market. In addition, Europe aims to collect plastic more intensively. The goal is to recycle up to 50% of all plastics by 2025. By 2030, the aim is to reach 55%.

Properly sorting plastic packaging is a crucial step in this whole story. Herein lies a great responsibility of both companies and consumers. Next, which plastics can be recycled most easily (and most difficult)? We made the following overview for this purpose:

Polyethylene terephthalate |

. Recyclable Recyclable |

. Used for food packaging, soft drink bottles, stuffing for soft toys and cushions, bank cards, etc. |

High-density polyethylene |

. Recyclable Recyclable |

. Used for water bottles, milk bottles, shampoo bottles, soft drink caps, etc. |

Polyvinyl chloride |

. Difficult to recycle Difficult to recycle |

. Used for tape, plastic window frames, kitchen utensil handles, garden furniture, etc. |

Low-density polyethylene |

. Recyclable Recyclable |

. Used for rubbish bags, cling film, plastic bags, etc. |

Polypropylene |

. Recyclable* Recyclable* |

. Used for tape, synthetic mats, children’s tableware, microwave dishes, etc. |

Polystyrene |

. Difficult to recycle Difficult to recycle |

. Used for Styrofoam (in packaging or as meat dishes) |

* Reality shows us that there is little PP material available for recycling. Consequently, the little PP material that is collected often ends up in the incineration cycle.

Good to know: to simplify the process of recycling, it is best to opt for mono-materials. Such mono packaging consists of 1 raw material. This can be plastic, but also cardboard, aluminium, wood, etc. By choosing 1 raw material, the packaging can be sorted and recycled much more easily afterwards. Handy!

4. Cardboard is not always the perfect alternative

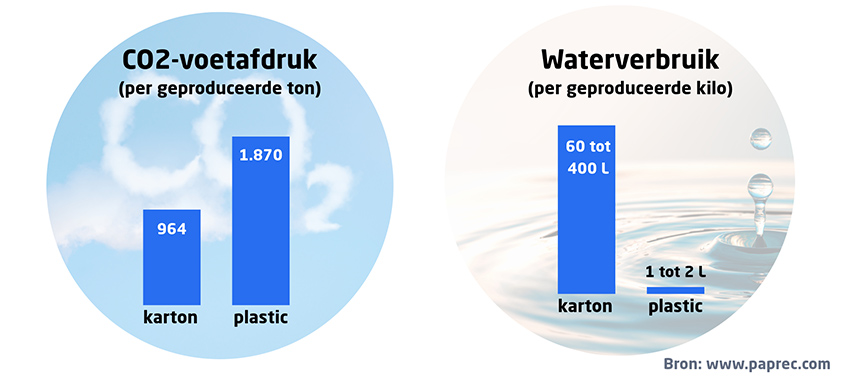

If we were to replace plastic packaging, what is the alternative? In most cases, cardboard is then chosen. But what about the ecological impact of these two materials? “1

As you can see in the comparison above, cardboard scores better in terms of carbon footprint. Plastic, in turn, is a better choice from the point of view of water consumption. So looking critically at the production process of these two materials, they both have their advantages and disadvantages.

In addition, you may wonder whether a cardboard box is always such a good shipping option? For less fragile products such as textiles or clothing, it is often better to use a shipping bag. Such a plastic shipping bag allows you to pack very compactly; without extra air inside. Moreover, thanks to the thin plastic layer, your items are optimally protected against water and moisture.

]5. Plastic packaging excels in re-use

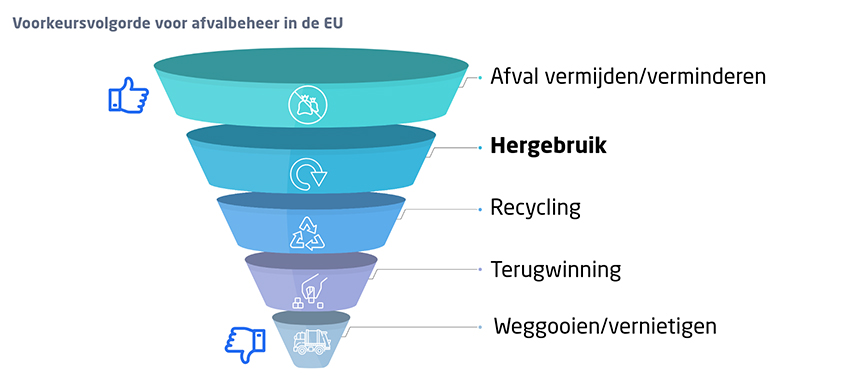

Single-use plastic products and packaging are routinely banned from Europe. Year after year, the EU imposes new rules on these “single use plastics“. Just think of the ban on thin plastic grocery bags, plastic straws, etc. However, the future of plastic lies in the fact that it is perfectly reusable. In this, it definitely excels. Moreover, reusing packaging is the major preference in EU policy.2

Fabrice Peltier, designer and ecodesign consultant, said the following in a recent interview with RAJA: “Plastic per se is not so much the problem as the lack of proper sorting and recycling. Therefore, packaging should be made simpler, for example by opting for a mono-material. More than ever, the packaging of the future must be the right packaging, properly tailored to your goods: choose the right material, the right size, the right weight, etc. Today, we live in an age of excess: too many options, too much packaging, too much consumption. Therefore, we should learn to reuse packaging more often or recycle it more easily. That way, we can reduce overall resource consumption in Europe.”

As Fabrice Peltier, among others, points out, the strength of plastic lies precisely in its reuse. If you were to reuse plastic packaging in a ‘closed loop’, it will quickly have a big positive impact. In that context, many logistics companies, for example, deliberately choose strong plastic solutions to equip their warehouse with. Below are a few of those popular products.

Warehouse bins |

Euronorm bins |

Plastic pallets |

| These bins are resistant to oil, grease and large temperature fluctuations, making them a good alternative to cardboard bins. | Stacking bins are easy to place on pallets, for example. They are strong, practical and recyclable. | Plastic pallets are a great solution for storing and transporting products. They are as robust as they are durable. |

Summary

There is a realisation that we need to optimise packaging. Not too much, and not too little. This includes a critical look at the materials used. How can you best protect your products and what customer experience do you want to give? Some companies simply cannot do without plastic for packaging their products. We have seen that it is also possible to choose bio-based solutions, or forms of recycled plastic. They are excellent alternatives to protect your goods efficiently and attractively.

It is up to you to ask the right questions and make your logistics as environmentally friendly as possible. RAJA is happy to think along with you.

As the largest distributor of packaging in Europe, RAJA is in the front row when innovations or new solutions are launched. Sustainability always plays a big role for us. Virtually all new products we offer do have an ecological angle to some extent. Years ago, for instance, we phased out polystyrene packaging and replaced it with alternatives made of recycled PE plastic or new innovations in paper and cardboard.In addition, a lot of our current plastic packaging has since been replaced by recycled plastic alternatives.Wim Gillis, Product Program Manager at RAJA Benelux

Sources:

1 www.paprec.com

2 www.consilium.europa.eu