One of the most widely used and effective systems to manage inventory and ensure an efficient supply chain is the FIFO method (First In First Out). What does it mean and what does it consist of? How does it work? Does it work for all types of goods? Let us try to answer all these questions, to understand when FIFO logic is a useful ally for warehouse management.

What is FIFO

FIFO is an inventory management strategy based on the principle of first in first out which can be translated as ‘the first product into the warehouse is also the first product out’. The concept behind this method is that the oldest products are used before than the newest ones.

When the FIFO method is applied

The application of the FIFO method is particularly suitable for seasonal items, which are subject to decay or expiry, whose consumption/use is closely linked to time intervalsbeyond which they incur spoilage or loss of value. We are talking for example about food products, pharmaceuticals and cosmetics, electronic components, fashion-related objects and goods.

FIFO: advantages

One of the main advantages of applying FIFO is the minimisation of waste. By using/shipping goods in order of arrival, the oldest products are used first, ensuring that the remaining items are those with the earliest expiry date. This reduces wastage of products due to spoilage or expiry. This helps to maintain a high level of product quality as it passes through the warehouse, but also allows you to manage stocks efficiently through regular rotation of items, reducing the risk of obsolescenceunsold goods and consequent financial losses.

How the FIFO method is applied and how it works

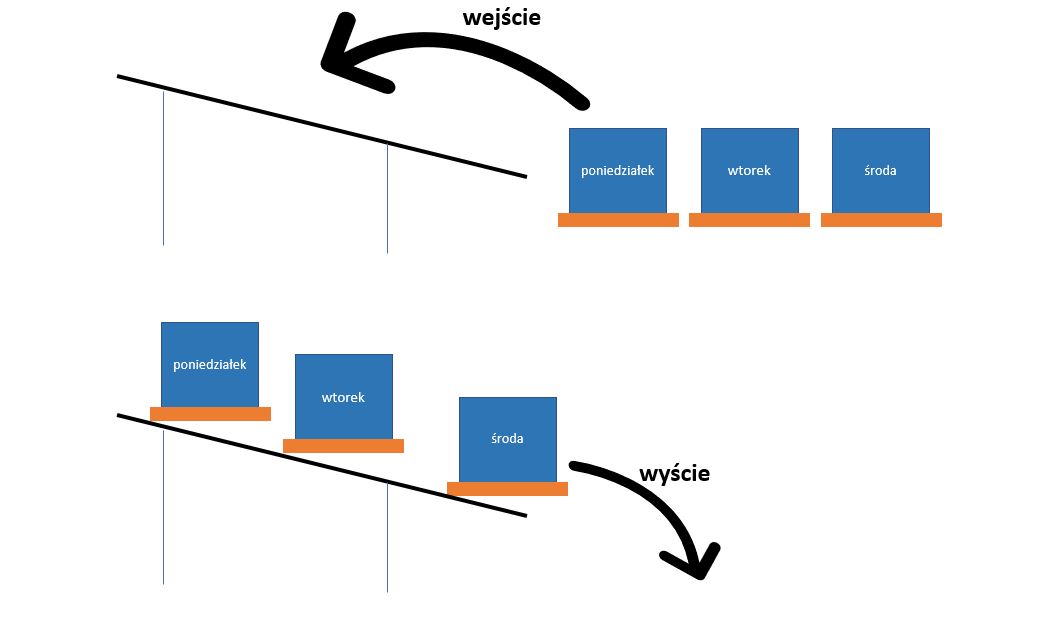

Those who decide to apply the FIFO method often organise the warehouse in such a way as to facilitate the picking of goods in order of arrival. For example, shelves are used that are accessible from both the front and the rear, so that incoming goods are placed on one side and outgoing goods on the other. Another aspect to be taken into account in FIFO management is the use of batches that indicate the date of entry of the goods or the date of production of the articles. This will allow older goods to be taken out, and thus to leave earlier. Let us clarify these dynamics with an example.

Example FIFO method

Let us take as an example a stock of tomato cans with different expiry dates. When a new load arrives, the new cans are placed at the back of the shelf, while those already in the warehouse are moved forward.

During the picking process, the staff selects the oldest tomato cans, picking them from the front and thus following the order in which they enter the warehouse. This ensures that the newest cans remain on the shelf and that products are sold before their expiry date.

The FIFO method, used in accounting and finance to calculate the value of inventories in the warehouse, also represents a theoretical model of the flow of goods.

The advantage of this method is that it takes into account the time factor in the calculation of the quantity of goods sold. For example, if half of the goods in the warehouse of tomato cans were sold in the previous year, I can consider the goods purchased from January to June as sold, as they are the first to have entered the warehouse. The remaining goods in stock will then represent the quantities purchased from July to December and not yet sold.

LIFO and FIFO

When we talk about the FIFO method, we must also mention the LIFO method – Last In First Out. Having seen what the former consists of, we can intuitively understand how LIFO works: the last products to arrive in the warehouse are also the first to be taken out..

While with products subject to expiry or decay, the LIFO method may entail risks of waste, obsolescence and financial losses, it is effective when the goods handled are not perishable and therefore the inventories can remain in stock and serve, for example, as capital, without the risk of spoilage.

From the point of view of warehouse organisation, the LIFO method method makes it possible to reduce the movement of goods within the warehouse. Incoming goods are positioned so that they are immediately accessible for picking again.

Between the FIFO and LIFO methods, the former is certainly the most common. For proper warehouse management, however, it is essential to understand the characteristics of the goods and the flow in order to choose the most suitable organisation method.

Solutions for Raja perishable goods

Where perishability of goods is a major issue in the supply chain, it is necessary to find efficient solutions for all stages of the process of storage and delivery to the customer.

Raja offers perishable goods packaging innovative and environmentally friendly. On the site you will find a wide range of containers suitable for transport, as well as pouches, bags, aluminium rolls and film suitable for optimum food preservation.

For proper preservation over time, vacuum packing machines are offered to minimise the perishability of goods.