Export goods that have to cover long transport distances, such as from Germany to overseas, are often exposed to extreme climatic conditions and high temperature and humidity fluctuations. Especially when transported by ship or through the air. These fluctuations can damage the packaged end product. Especially when loading at ports, the goods are exposed to the constant danger of moisture. How can this moisture formation be prevented?

Absorbing temperature fluctuations during logistics and transport

The solution is relatively simple and everyone who has already ordered shoes on the Internet probably knows it. When you open the shoe box, you sometimes come across this small bag with indefinable contents. Together with the tissue paper in which the shoes are often wrapped for protection, it usually ends up in the rubbish immediately. But this little bag is a real performance miracle and helps to ensure that the goods, in this case the shoes, arrive in dry condition. Desiccant bags provide moisture protection and prevent the formation of condensation. The desiccant removes moisture from the surrounding air and prevents the items in the packaging from becoming dewy when the temperature drops.

Another option for reducing moisture, especially when transporting goods in trucks or containers: desiccant containers and desiccant chains. The special features and advantages of each product are shown below.

Versatile use of desiccant bags

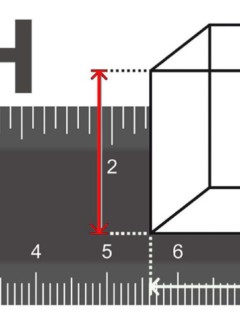

They are not only suitable for use in shoe boxes, they also protect against moisture when transporting electronic equipment, machines, optical devices, food packaging or pharmaceutical products, etc. Our desiccants are made of natural materials based on alumina, silica gel or silica and are therefore non-toxic. The DIN standard 55473 for “Packaging aids – Desiccant bags – Technical delivery conditions” defines a desiccant unit (TME) as the quantity of desiccant that absorbs at least 6 g of water vapour at an air temperature of 23 °C (+/- 2 °C) and a relative humidity of 40 %. 1 TME thus absorbs 6 g of “moisture” and thus has an absorption capacity of 6 g. Especially for technical products, bags with desiccants should always be used in combination with a so-called barrier envelope, which can be a PE film with 150µ, for example. By sealing the goods in film, a sealed climate zone is created and an exact determination of the type and quantity of desiccant bags is possible. How many desiccant bags are needed for transport depends on various factors:

- the volume of air enclosed in the packaging (dimensions of the packaging)

- the material used for the outer packaging (type of filling material)

- the climatic conditions during packaging (relative humidity and temperature)

- the duration of transport and storage times

- the maximum permissible humidity inside the packaging.

With the help of this information, we can calculate how much desiccant is needed for your requirements so that everything stays dry. And with the help of these small bags, the shoes also make it “dry feet” overseas.

How desiccant bags work and what they are used for

The humidity content in a container fluctuates due to weather influences such as temperature and air pressure, which can cause condensation of water vapour. In closed containers, the packed goods undergo these strong climatic fluctuations, which can cause moisture damage through the formation of condensation. In the case of extreme climatic fluctuations, for example when crossing different climate zones, the effect is even stronger. This can result in moisture-related damage to both the packaging and the goods themselves. This ranges from swollen cardboard packaging and mould growth to damage to the actual goods being shipped. How can this be counteracted?

Compensate for climate fluctuations, avoid condensation water

To protect the quality of the export goods during transport, it is important to compensate for climatic fluctuations and thus prevent condensation. Desiccants can help here because they absorb moisture. They offer good protection by absorbing excess moisture and thus neutralising the formation of condensation inside closed rooms.

And this is how the desiccant containers work

The desiccant container attracts the air saturated with moisture via a special breathable membrane. The hygroscopic salt contained in its interior retains it in the form of water, thus preventing new evaporation and condensation cycles. The granules can absorb up to four times their own weight! A protective layer, in turn, keeps the liquid in the desiccant container until disposal, thus ensuring long-lasting protection.

This type of moisture protection is suitable for almost all containers and trucks. In addition, the handling is very simple, because the dehumidification material can be placed quickly and easily, e.g. by means of hangers. If there is no possibility of suspension, individual containers with desiccant can also be placed directly on the goods or the loaded pallet. The desiccant containers are diffusion-tight, i.e. the absorbed moisture can no longer be released to the outside, so there is no danger of “leakage”.

Protection against leakage for hazardous goods

But there are situations in which leaking liquids can become much more unpleasant. When transporting hazardous goods , chemicals and dangerous liquids, for example, it is essential to take precautions against possible leakage. The material that is used must meet several requirements at once:

It must not be easily flammable, it must be absorbent and, with regard to transport costs, it must be light. The material itself must not be harmful to health under any circumstances, ideally it should be reusable and it must be possible to dispose of it without damaging the environment.

Vermiculite

A desiccant used in connection with the transport of dangerous goods must fulfil various requirements: It should be lightweight, non-flammable and absorbent. Like vermiculite . The naturally occurring clay mineral is used wherever liquids need to be reliably regulated and absorbed. Here, the material benefits from its harmlessness: because only materials that are completely harmless to health can be used in direct contact with food, animals and people. For example, the mineral is used in cat litter, but also in vegetable cultivation and in animal husbandry to regulate heat and humidity.

Regulation of heat and humidity: also a big issue in the building industry. Vermiculite is therefore often used for thermal insulation and fire protection. Another unbeatable advantage of the material: its melting point is 1,350 degrees Celsius, it is considered incombustible with a class A1 (no smoke development, no burning dripping/falling off according to building material class DIN 4102-1) and is electronically non-conductive.

The decomposition of vermiculite and the production of vermiculite

There are currently 550 known sites worldwide, many of them in the USA; but finds have also been documented in Australia, Brazil, China, Germany, France, Canada, Madagascar, Austria, Russia, Switzerland and South Africa. The raw material is heat-treated at around 1,000 degrees Celsius. In the process, the rock layers are driven apart and the moisture they contain evaporates (exfoliation). The process produces small, worm-like curved particles (vermis = Latin for worm), which are very light due to their high air content (100l of vermiculite granulate weigh about 9kg) and at the same time are able to absorb 5 times their own weight in moisture. Vermiculite granules are typically composed of silicon 38-46%, aluminium 10-16%, magnesium oxide 16-35%, iron oxide 5-13%, titanium oxide 1-3%, calcium oxide 1-5%, potassium oxide 1-6%, moisture 3-16% and other components 1-2%.

Vermiculite in the transport of dangerous goods

Particularly strict specifications apply in the transport of hazardous goods. Vermiculite is approved as an absorbent material for hazardous goods transport and, thanks to the above-mentioned properties, fulfils its task with absolute reliability. Processed as granules, vermiculite is the ideal material for cushioning and protecting your potentially hazardous products. Perfectly surrounded by vermiculite granulate, the container with liquid is optimally protected against shocks and vibrations. Should the container with liquid substance nevertheless be damaged, the liquid will be absorbed without anything escaping from the box. We recommend that you line the box with a film before filling. Although leakage of the granulate is extremely unlikely thanks to the relatively coarse grain size (for strength M, the diameter of the individual balls is given as approximately 4mm), minor dust formation is possible).

How is vermiculite disposed of?

If the container with the hazardous material is undamaged, the granulate can simply be used again and again and in the end, provided it never came into direct contact with harmful substances, simply be disposed of in the household waste – or, after use, be used in the garden mixed with soil as a natural fertiliser.

Moisture indicator for particularly sensitive products

If particularly moisture-sensitive items are being shipped, such as electronic devices, metals and optical instruments, it is advisable to also use a moisture indicator. It indicates whether the relative humidity in the vicinity of your cargo has exceeded the reliable value during transport. The measuring strip simply has to be placed inside the packaging. The humidity indicators are made of special paper and are impregnated with different solutions that react to air humidity.