Every company that has to ship goods on pallets is responsible for loading and packing the pallet in such a way that a stable and secure loading unit is created. After all, the pallet should arrive at the recipient just as it was sent. It has to be equipped for this, because it will have many an adventure on its “journey”. Whether by truck, train, ship or plane – immense forces act on your goods during transport.

Load securing is essential – by hand or by machine?

Stretch film is essential for creating such a load unit. Securing pallets with stretch film is particularly safe and particularly economical, but it is a science in itself. Stretching by hand is like a complicated gymnastic exercise, as the pallet has to be wrapped mainly in a stooped position and walking backwards. If more than 10 pallets have to be loaded ready for dispatch every day, it is therefore worthwhile to purchase an automatic stretch wrapper. Because stretch wrapping machines not only protect the back health of the employees, but also save material and working time. In another article we have described how the load can be optimally secured with stretch film.

Which pallet wrappers are there – and which is suitable for what?

With the large selection of stretch machines, choosing the right machine is usually not easy. In the following, we would therefore like to present the individual machine variants to make the selection a little easier.

First of all, it is important to think about the basic conditions and needs in advance of the purchase, for example:

- How many pallets must be wrapped per day?

- What is the weight per pallet (maximum and minimum weight)?

- What is the size of the pallets length x width x height (always the same size or do the sizes vary)?

- How much storage space is available for the machine?

- What type of products are involved? Do sensitive products have to be wrapped?

This is where the application tension of the stretch machine plays a role. The application tension is also referred to as the wrapping (tensile) force, i.e. the force with which the stretch film is wrapped around the pallet. Light or delicate packages require a low application tension and heavy packages require a high application tension. Many pallet wrappers and stretch robots offer the possibility to adjust this application tension. - What does the load or the load carrier look like (underhang, overhang)?

- Are the pallets homogeneously or inhomogeneously packed?

- What properties should the films used have (dust protection, securing, etc.)?

- How large is the available storage space (inlet floor, with recess, with ramp)?

- How are the pallets transported internally (pallet truck, electric pallet truck, forklift)?

- What colour are the products (photocell for dark products/black film)?

Manual stretch machine

-

This is what a manual stretch machine can do

For a low turnover of up to 30 pallets per day, a manual stretch wrapper, such as the Wrapman, is perfectly adequate. Compared to manual wrapping, material costs can be saved by up to 50%.

-

Why is the manual stretch wrapper so effective?

The advantage of these machines is that they already have motorised pre-stretching. If a film is wound without pre-stretching, the film is only slightly stretched by the application tension and retains approximately the length available on the roll. However, due to its stretchability, stretch film can be extended many times over. Many pallet wrappers therefore have pre-stretching or pre-stretching functions with which the film can be pre-stretched. The stretch indicates the percentage by which the film can be stretched until it tears when it is applied to the pallet. Thanks to its restoring force, the film returns to its original position and in this way the pallet load is optimally fixed. Standard hand stretch films that can be stretched by 100 % can be used for the Wrapman.

-

These are the advantages of a manual stretch wrapper

The advantage of the manual stretch wrapper Wrapman is clearly its mobile application, because pallets can be stretched directly at the location where they are. The machine is driven to the pallet and has to be manually guided around the pallet, a push button is used to raise and lower the film carriage. Only a distance of 60 cm is required to the pallet, the machine can be used on any pallet size and shape. After the stretching process, the wrapper can be placed anywhere and takes up very little storage space. The output of 30 pallets per day is rather low, but the purchase costs are also significantly lower than, for example, with a stationary pallet wrapper.

Stationary pallet wrapper

-

What the stationary pallet wrapper can do

The stationary pallet wrapper can handle up to 400 pallets per day. Stationary pallet wrappers are particularly suitable for companies that have sufficient storage space and usually use the same pallet size. In the case of pallet wrappers with a turntable, the pallet is positioned on the turntable. The film is knotted to the pallet or fixed to the turntable, then the device is activated at the push of a button and the turntable rotates around its own axis. In this way, the pallet is wrapped.

-

The advantages and disadvantages of the stationary pallet wrapper

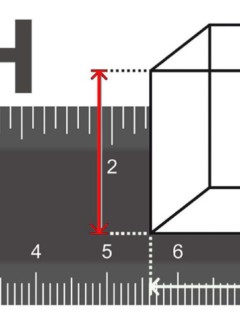

These machines stretch the film between 120% and 300%, thus reducing film consumption. Different settings and programming such as head and foot wrapping additionally increase the efficiency. Disadvantage of this variant: The pallet wrapper is bound to a fixed location and requires a lot of space due to the turntable and the additional drive-up ramp. Each pallet must be transported to the machine for stretching. Moreover, the systems with turntables are mostly intended for pallet dimensions up to a certain size (e.g. up to 1200×1000 mm with a diameter of the turntable of 1650 mm). In addition, the maximum load capacity must be taken into account for the version with a turntable; a pallet wrapper with a rotating arm is necessary for heavy pallets over 2 tonnes.

Wrapping robot

-

What the wrapping robot can do

Depending on the version, the wrapping robot can handle between 150 and 250 pallets per day and is therefore very efficient. These machines are particularly suitable for companies with a high frequency of goods but little space in the warehouse.

-

Advantages of the mobile pallet wrapper

A mobile stretch or wrapping robot is a very variable solution that combines the advantages of both previously mentioned options. The robot is driven up to the loaded pallet, the film is fixed to the pallet and the machine does the rest completely independently. The robot can be programmed and automatically detects the height of the pallet. As with the manual pallet wrapper, the mobile pallet wrapper can be used almost anywhere and can be stowed away to save space when the job is done. The robot requires a minimum pallet size of 800x600mm, otherwise the pallet size does not matter. The wrapping robot is also suitable for oversized pallets.

With the right pallet wrapper and the right stretch film, nothing stands in the way of securing the pallets.