In the field of consumer packaging, the wildest things are possible when it comes to printing. A glance through the supermarket shelves or the presentation areas of well-known electronics suppliers shows an almost sensory overload of colours, patterns, embossing… Of course: packaging should attract attention, enhance value and ultimately: sell. This can only be achieved with print…

How can packaging bind attention?

In the struggle for attention, manufacturers choose unusual forms of packaging. However, there are relatively narrow limits to creativity here, as retailers only prefer to list packaging that is easy to handle, stackable and has a secure stand! Also attention-grabbing are original functions (such as haptics, opening, reuse?) and, most importantly: the print! After all, images and colour have a decisive impact on the brand image and direct emotions. Visual stimuli ultimately lead us to grab the product – or not.

So there is one way to design the packaging: Either the print is applied directly to the packaging, or a kind of “diversions” is taken with the help of stickers, printed adhesive tapes or labels or even banderoles. Both have their advantages and disadvantages:

Printing packaging directly

If the print is applied directly to the packaging (i.e. the cardboard box, the shipping bag, the film, etc…), this usually has a more “valuable” effect on the customer. While printed adhesive tapes may seem a bit “arbitrary” and “interchangeable”, printing directly on the carton symbolises a certain size and success of the company: the company is “big enough” to have its own cartons. Directly printed packaging also symbolises a certain durability – because printing on cardboard and the like only pays off after a certain number of copies have been produced, larger quantities are usually produced in advance. It should be ensured that no changes are made to the brand image, logo or message for a longer period of time. Especially in highly regulated market situations, however, such as printing on food packaging, surprising new laws with information obligations can sometimes make reprinting necessary, whereby the legislator often provides transitional regulations for packaging that has already been printed.

And here lies a disadvantage of directly printed packaging:

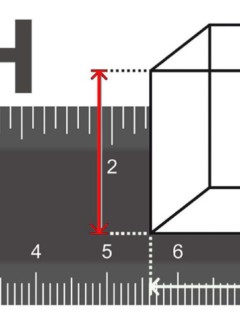

Printing your own shipping cartons is usually only worthwhile if you have a certain print run. It is somewhat more cost-effective to produce your “own” carton if you do without cartons of different sizes, as the whole thing can then be done in one print job. Disadvantage here: For reasons of sustainability, but also for optimal product protection and last but not least to save postage or transport costs, we usually recommend our customers to use several carton sizes and variants and to pack and ship in the appropriate carton in each case without unnecessary padding material. In addition, you may also be more flexible in the printing process and the print image with printed adhesive tapes or labels.

What is possible when printing on shipping cartons?

Everything. But here too: A question of cost The classic and most requested by us is the 2-sided printed cardboard box, printed in one or two colours, in so-called line printing.

Line printing – what is it? In so-called line printing, 100% coverage is used. This means that printing inks are applied in a defined way and without gradations and mixtures. Where there is red, there is red – where there is black, there is black. Line printing according to the all-or-nothing principle allows no shading, no colour gradients, no mixed colours.

Relatively unusual and therefore still very eye-catching: the shipping box printed on the inside!

But cardboard boxes can also be printed using scale printing or four-colour printing. Here, the so-called standard colours cyan (blue), magenta (red) and yellow (yellow) and additionally key (deep black) are mixed with each other in several print runs, virtually all conceivable mixed colours can be produced.

Tell us what you want – the appropriate process is then up to us Our customer advisors are also happy to support you if the perfect motif has not yet been found – and coordinate the right colour values with you.

Direct printing on cardboard and foil

Cardboard packaging such as folding boxes, pillow boxes or slip lid boxes can be printed relatively easily. This type of sales packaging is the most common product packaging. As a rule, they are printed using the offset process, which is the most commonly used process for medium runs; gravure printing is also an option for long runs. Punch-outs and so-called viewing windows (open or glued behind, e.g. with PET film) are often used here. If there is a risk that the packaging will be exposed to moisture, it is possible to “seal” the print with a type of varnish. In practice, however, if moisture is expected, film packaging is more likely to be used.

There is also a choice of possible printing processes for film packaging such as film mailing bags. Besides flexographic printing, digital printing and gravure printing (for long runs), thermal transfer and hot or cold foil stamping are also common. Rather tricky in connection with foil: offset printing, here there is then the special UV offset printing. In the area of film mailing bags, opaque, printed coex films (a composite material made of several film layers) are often seen; they are popular in the shipping of clothing, among other things.

Printing without a border? If something is printed without a border, it is also called borderless. Foils as well as cardboard can be printed without margins. Talk to us about the special features that need to be taken into account here! Foils printed with dropped edges, for example, could cause problems when sealing…

One for all: screen printing is indeed suitable for almost all materials and shapes. Screen printing works for textiles (e.g. reusable carrier bags), glass, plastic, round or misshapen objects and is therefore often applied afterwards, i.e. on the finished packaging, even in smaller runs.

Printing on packaging – in a “roundabout” way

Adhesive tape, banderole, stickers and co.

Solutions such as printed adhesive tape, banderoles around or stickers on the packaging are often used when either the information is only to be attached to the product temporarily, or when the packaging itself cannot be printed itself for handling reasons. Even though these solutions require a further step in the packaging process – the application of the banderole, tag or sticker – this variant is still cheaper in many cases than applying the print directly to the product packaging. For example, bottles are provided with cardboard tags or so-called hangtags, banderoles (also self-adhesive if desired) are often found around shrink-wrapped or vacuum-packed foodstuffs, on chocolate or flowers or even salad or even cardboard boxes. In the case of printed adhesive tape, this additional work step is even unnecessary: here, the tape used up to now is simply replaced with the printed tape.

Banding

With printed banderoles you remain particularly flexible in packaging printing. They are either prefabricated to fit your individual product, delivered closed as a band and “put over” it, or they are delivered on self-adhesive band strips and then glued to the product itself.

For example, already existing packaging can be provided with additional information, temporary information (often used for raffle promotions and other seasonal deviations from the “normal programme”). The application possibilities of cardboard and paper banderoles are extremely versatile. Not only can they be integrated into existing packaging concepts in no time at all, they can also replace outer packaging altogether. Unprinted, simple product packaging can be upgraded and refined particularly inexpensively with the help of the banderole. The shape and format of the banderole can be chosen almost freely, and there are (almost) no limits to the printing process (offset, digital or flexographic). Optical highlights can be set here, for example, with special colours, hot foil stamping or partial varnishing.

A good argument for banderoles: The environment! Banderoles often replace outer packaging. Especially in the area of food packaging, banderoles are often a good compromise. (Attention: When printing on banderoles that come into direct contact with food, make sure to use low-migration inks and processes! However, origin, shelf life, etc. can easily be printed on a banderole or a sticker. In this way, much less material is used – and thus less is thrown away.

Sticker

The same advantages as for banderoles essentially also apply to stickers. In addition, similar to a glued banderole, there is a certain safety aspect or freshness aspect: the sticker (gladly additionally with a consecutive serial number or similar) serves at the same time as a safety seal. If the packaging is opened, this becomes visible on the torn sticker.

When it comes to printing, the options are endless. Labels differ not only in the type of printing, shape and finishing, but also in the type of backing material and adhesive. Labels on products such as cans or bottles are predominantly wet-glue labels, for example. Similar to wet glue labels, these labels are not adhesive at first, they only develop their adhesive power when they come into contact with water or, depending on the design, with label glue.

Special forms and special uses:

A very special form of label printing is often seen in the food and beverage sector or in drugstores. Here, packages are filled in transparent packaging such as bottles, tubes or cans – to convey confidence and value: You get what you see! A visibly affixed label would reduce the impression of value, and printing the packaging itself is technically difficult and, above all, expensive! The solution? No-label look labels.

No Label Look labels are special transparent labels that are distinguished by their special properties of transparency. The edges that are usually visible on printed labels almost disappear. In addition, the view through the label is unobstructed and clear, giving the product a far higher quality appearance than with ordinary transparent stickers and films. Applied properly to your product, the customer can hardly tell the difference between a direct print and a No Label Look label solution. Your wallet can. Because the production of No Label Look labels not only offers visually appealing results that are particularly suitable for premium products, but is also very economical compared to direct printing.

How does it work? The secret lies not only in the use of a highly transparent film (polypropylene films are also extremely malleable and can be perfectly applied to curves, for example), but also in the use of the right adhesive. The adhesive must be completely clear so that the transparency does not become milky or cloudy. Another important factor is the “liner”, i.e. the substrate on which the label is placed before use. If this has a fibre, then this unrest will be transferred to the adhesive and it will be unstable, i.e. milky. If, on the other hand, this is also a film (Clear-On-Clear), then no paper fibre will disturb the adhesive and it will remain calm, in the sense of not being milky.

Labels suitable for food

Foodstuffs are usually very difficult to label due to the respective surface structure. The rough or even greasy surface is a difficult undertaking for many types of adhesive, because either there are not enough bonding points between the adhesive and the surface or the adhesive is generally unsuitable or even approved for application. Both cases lead to detachment of the adhesive, i.e. not to the desired success. Furthermore, adhesive types must not distort the characteristic features of a food (e.g. odour) and must not transfer any substances that are hazardous to health to the food to be glued. This is referred to as “low migration” adhesives and inks.

Furthermore, residue-free removal may be required as an additional criterion, which in turn reduces the respective selection.

If food is to be labelled, this requires complex planning in advance. Our partner INnUP has compiled the most important facts very clearly here: Innup – The Labelling of Food. Are you looking for suitable packaging for food? Or are you thinking about printing food packaging? Then you can find more information in our blog: What is the purpose of food packaging?

Hangtags, carton tabs or bag tabs

Hangtags are universally applicable labels made of paper or cardboard that can often add considerable value to consumer contact. The hangtags, which are available in various forms, can be found, for example, as labels on items of clothing and fashion accessories, as an enhancing eye-catcher for different types of packaging or also as an additional label on bottles. Above all, goods and objects that cannot be directly glued or equipped with a label can very easily be provided with a hangtag.

Product information, brand messages, company logos and care or warranty information can be placed on the tags and implemented in a graphically appealing way. Hangtags are also popular as part of competitions and as exclusive admission cards for a special promotional event.