In our article today, we take a closer look at the autolock box. They are popping up everywhere, from the packing stations of big e-commerce companies to small start-ups. And with good reason, because they allow you to save a huge amount of time. An autolock box has a bottom that folds shut automatically without effort. This makes preparing a parcel up to 2.5 times faster compared to a standard box.

1. What are the advantages of an autolock box?

► Save time.

► Save on packaging tape.

► Pack safely thanks to the reinforced bottom.

► Pack environmentally friendly thanks to the recyclable cardboard.

Now why should you use an autolock box instead of a standard box? At the end of the working day, you will find that using an auto-bottom box saves you in a lot of areas. We have already mentioned time. A box with automatic bottom is set up in as little as 9 seconds. With a standard box, it takes an average of 22 seconds. A packer handling 250 packages a day thus saves 1 hour of work!

Apart from time, you also save on packaging tape. You only need to tape your box at the top. For the bottom, you use the autolock system. A box with automatic bottom also allows you to pack a product even more safely. The folded bottom is very strong and offers a double cardboard layer. All these boxes also have an outer lining with kraft paper. This provides another layer of protection against external influences (such as moisture, UV light or dust). Last in the list of advantages, we should also mention their environmentally friendly nature. All autolock boxes are recyclable, thus reducing waste production. Nice touch.

2. How do you use an autolock box?

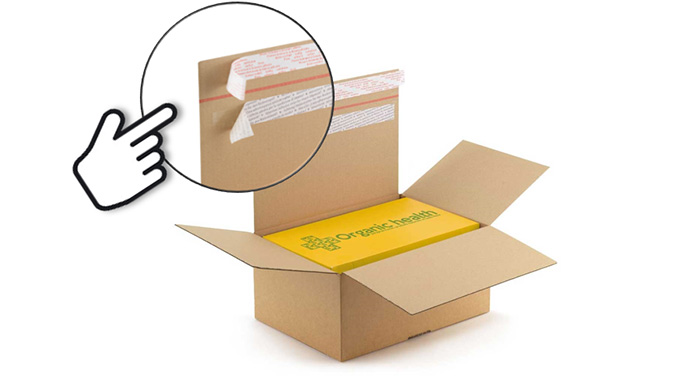

Just what makes an autolock box so unique you might ask? The secret of this box is in the bottom. Let’s take a standard box. First you have to unfold the box, then put the flaps of the bottom in the right position. Then you have to tape the bottom. Only then can you start packing. With an autolock box, you skip all those steps. You just push on the sides of the box and the bottom automatically secures itself in the right position. After that, you no longer need packing tape either.

- An autolock box is 2.5 times faster to set up than a standard box?

- A packer handling 250 parcels a day saves as much as 1 hour thanks to an autolock box?

- More than 650,000 autolock boxes have already been shipped in the Benelux via RAJA in 2017?

For the most common standard boxes, there does exist an alternative in the form of an autolock box. Both within the range of single corrugated boxes and double corrugated boxes, you can therefore opt for an autolock box. Want to see concretely how fast you do pack with an autolock box? Then watch the video below:

]3. What types of autolock boxes exist?

► Standard autolock box: this is the simplest and cheapest variant, available both as a single-wave box and as a double-wave box. By simply pressing on the sides, the self-locking bottom automatically secures itself.

Autolock box with self-adhesiveclosure: in addition to an automatic bottom, this box also features a self-adhesive closure at the top. This allows you to close the box effortlessly without using packaging tape. Thanks to the tear-off perforation, your customer can easily tear the box open again, with the same ease as with a zip.

► Autolock box with return closure: this is undoubtedly the most versatile box in the e-commerce sector. Besides an auto-bottom, it also features a tear-off perforation and two closures. Now why two closures? You use the first closure yourself to close the box when packaging. The second closure is for your customer when he would like to return the box. For any e-commerce company, this is an indispensable box if you want to offer an extra service to your customers.

► Autolock box with variable fill height: these boxes with automatic bottom are quickly assembled and easily adapt to the height of your products. This is possible because they are fitted with creasing lines. The same box can be adjusted to up to 13 heights. So you save time when setting up the box, but also in filling material, as this box is easier to adjust to the size of your product. Another win-win situation.