Earlier we looked at how best to use wrapping film and the benefits of coloured wrapping film. Time now to go one step further. Do you ship more than 15 pallets per day? Then you should consider buying a film wrapping machine. With this machine, you will save a lot of time and use less wrapping film. You will also notice that your pallets are much more stable and firmly wrapped. Whether your pallet has to travel a long, bumpy road, face a raging sea or is high in the clouds, your goods will reach your customer in perfect condition. Read on to learn which machines are best for wrapping your pallets.

When do you opt for machine wrapping?

Will it be wrapping with a hand unwinder or a mechanical film wrapper? There are specific applications for each:

► Hand unwinders for wrapping film are very versatile and suitable for both large and small products, homogeneous or heterogeneous goods and loads with or without a pallet. For companies that ship only a few pallets daily, hand unwinders for stretch film are a convenient and inexpensive help. These strong dispensers are equipped with two handles. You attach the roll of stretch film to the dispenser and then get straight to work.

► Hand unwinders for wrapping film are very versatile and suitable for both large and small products, homogeneous or heterogeneous goods and loads with or without a pallet. For companies that ship only a few pallets daily, hand unwinders for stretch film are a convenient and inexpensive help. These strong dispensers are equipped with two handles. You attach the roll of stretch film to the dispenser and then get straight to work.

► If your company prepares more than 15 pallets for shipment every day, a machine-based solution is an appropriate investment. Not only will you save your warehouseman’s back, but you will also save a lot of time and wrapping material. A mechanical film wrapper never uses more film than is strictly necessary. It also wraps much faster and more correctly than a human could do.

| Manual wrapping |

Machine wrapping |

| Versatile: for homogeneous or heterogeneous loads, large or small products, with or without pallet. | Save film: stretch the film as much as possible and never use more than necessary. |

| Less than 15 pallets per day. | More than 15 pallets per day. |

| Work ergonomically. | |

| Save time: the machine does all the work. |

Which film wrapper should you choose?

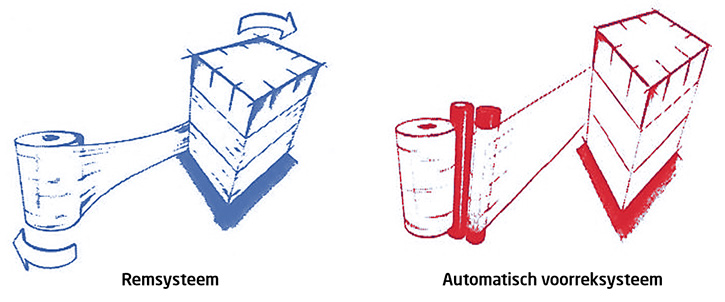

]Broadly speaking, you have a choice of two types of film wrappers: with a braking system or with an automatic pre-stretch.

- Mechanical braking system = Those with a braking system are technically the simplest and therefore also the cheapest. The film is stretched by means of a brake (up to a maximum of 100%). As a result, the film narrows a little. You will therefore need slightly more film per wrap. To avoid this, it is best to use pre-stretched film with this system.

- Automatic pre-stretch system = The machine will optimally pre-stretch the film – by up to 400%. The film rolls between two motorised axes placed very close together. The result of this process is a film that is no longer narrowed and covers your pallet to the maximum extent.

As you can see below, you have a choice of different versions of machines:

| Type of film wrapper .  |

Number of pallets per day & Type of load  |

Advantage . |

| (1) Mobile wrapper | – From 15 pallets per day. – Homogeneous or heterogeneous loads. |

The cheapest solution. |

| (2) With turntable* | – Up to max. 50 pallets per day. – Homogeneous loads. |

The mechanical brake ensures even winding. |

| (2) With turntable and front rack system** | – Up to max. 150 pallets per day. – Homogeneous or heterogeneous loads. |

With automatic pre-stretching for max. film saving. |

| (3) With swivel arm* | – Up to max. 250 pallets per day. – Unstable loads and goods too heavy for a turntable. |

With rotating arm that wraps the film around very heavy pallets wrapping. |

| (4) Wrapping robot*** | – Up to 150 or 250 pallets per day. – For loads that cannot be placed on a wrapping platform due to their shape or weight. |

Automatically rotates any load (min. 60 x 60 cm). |

* Equipped with braking system.

** Equipped with automatic front rack system.

*** Available in a variant with a braking system or an automatic front rack system.

► 1. Mobile wrapper

We start our comparison with the mobile film wrapper. It is the cheapest solution, but it still requires manual effort. A warehouse worker drives the device up to a pallet and walks around it.

The film is applied with constant tension and holds the load perfectly in place, without any damage. The mobile film wrapper is height-adjustable so you can work with rolls of wrapping film of different widths.

► 2. Film wrapper with turntable (+ pre-stretch system)

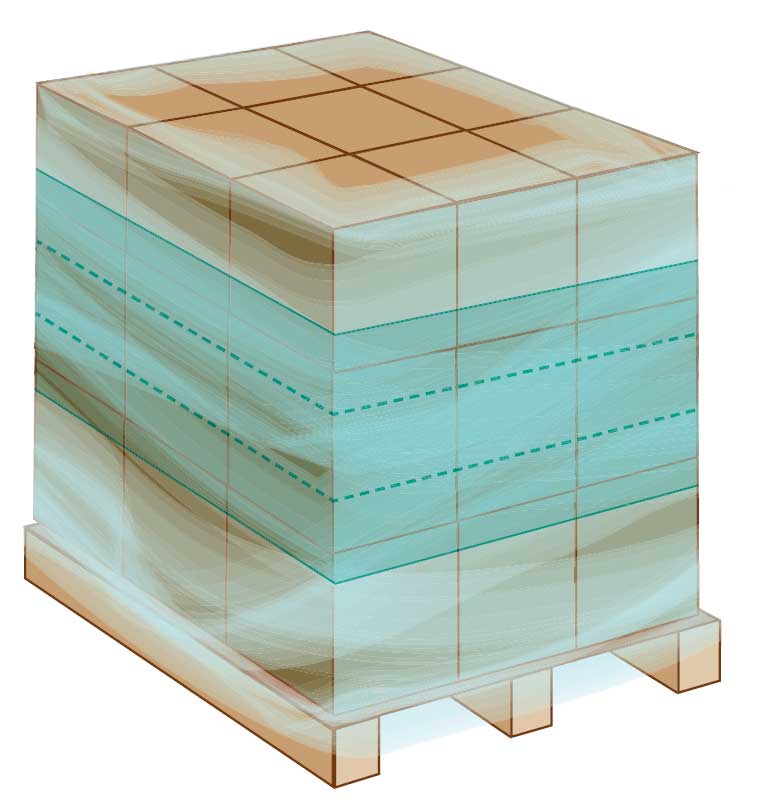

]Foil wrappers with a turntable are usually used for standard pallets (up to 2000 kg), fitted with a homogeneous load. You place a pallet on the turntable, tie the film at the bottom of the pallet, press the start button and the turntable rotates on its own axis. In this way, the film is wrapped around the pallet with constant tension: super safe and precise.

With the model with pre-stretch system, you also easily wrap heterogeneous loads or goods that are easily compressible. This machine’s automatic pre-stretch system can theoretically stretch the film by up to 300%. This makes better use of the quantity of film and you end up with lower consumption.

► 3. Film wra pper with rotatingarm

]The film wrapper with rotating arm wraps much faster than its equivalent with a turntable. This is because your load simply stands still and is not affected by the rotating force of a platform. It is also an ideal solution for wrapping very heavy loads (over 2000 kg). These cannot always be placed on a turntable.

This wrapping machine stands for safe use: the rotating arm is fitted with shock-absorbing foam. It stops immediately at an obstacle or if you press the emergency stop button. Moreover, it is also ergonomic: the film holder always stops at man height so that your warehouse worker can change the roll more easily.

► 4. Wrapping robot

A wrapping robot is a multifunctional device that is easy to move and wraps pallets fully automatically. Regular and irregular shapes with protruding or projecting parts: this device can handle it all. The wrapping machine rotates itself around the pallet, maintaining a constant force on the wrapping film. Finally, it saves you a lot of space: when you finish wrapping, you store it safely outside the work area of your warehouse.

Moreover, the model with a pre-stretch system helps you save a lot of wrapping film. If you use stretch film with an elasticity of, say, 250%, 1 metre of film can theoretically be stretched to 3.5 metres.