The 7 tips in this article bring more productivity to your shop floor. How do you adjust a packing table correctly? What is the best way to move heavy goods? How do you facilitate order picking? We provide you with answers to all these questions in this article, always with the physical well-being of your colleagues in mind.

Seven tips for increased productivity in your warehouse

► 1. Adjust your packing table correctly

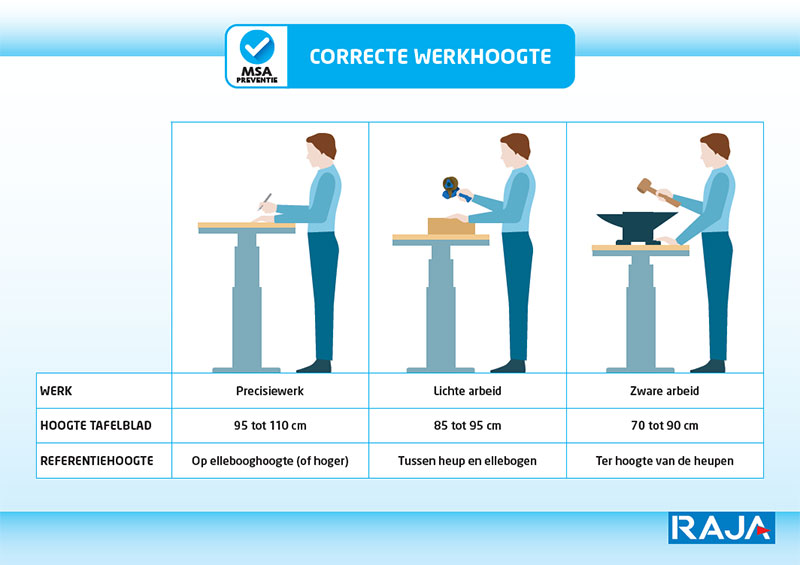

Although this first tip speaks for itself, we see that there is still room for improvement in many companies. A poorly placed packing table is a source of a lot of physical complaints. From bending down too often to pick up low placed material, to standing straight in the same position for long periods of time. And that, of course, undermines productivity. Best keep these guidelines in mind:

-

Place all work material in a 60° radius around your packer, with everything within reach.

-

Does your packer stand upright for more than 2 hours a day? Then provide a standing aid or chair.

-

Adjust your packing table to the right height. Check the diagram below to do so:

► 2. Create a pleasant workplace

Light, sound, temperature… It all has a bigger impact on our productivity than you might think. Here are some key points to consider:

-

Temperature: too hot and everyone becomes sluggish and languid. Too cold and your warehouse workers will suffer from stiff muscles and stiff joints. The golden mean? Keep the temperature between 14 and 18 °C.

-

Brightness: too dark and you will suffer from eye strain more quickly. Too bright and your warehouse workers risk suffering from headaches. In a factory warehouse, it is generally recommended to provide a light level of between 100 lux (for the aisles) and 300 lux (for the packing area).

-

Noise: too much noise can be a very disruptive factor on the shop floor. Therefore, make sure your warehouse has smooth floors as much as possible. First of all, bumps cause a lot of rattling and clattering when a fully loaded forklift truck drives over them. In addition, those bumps in the road also cause shocks to the body. And that is something we prefer to avoid.

► 3. Move and lift your goods efficiently

Lifting and moving your goods smoothly is an important factor for good productivity in a warehouse. For slightly heavier or bulky goods, warehouse workers make best use of these tools:

-

Choose an electric pallet truck to move around more easily with your heavy pallets. Instead of covering kilometres on foot, just jump on the back of the pallet truck and ride along comfortably. Make sure the driver of a pallet truck always has enough braking distance. Indeed, brusque braking is very stressful for neck and shoulders.

-

Choose a scissor pallet truck to lift goods up to 80 cm off the floor. This allows your warehouse workers to work at hip height, which will be better for their backs.

-

Transporting and lifting at the same time is best done with a lift table. The hydraulic foot pump raises the goods to the optimum working height.

► 4. Optimise order picking

Pallet trucks and lift tables we have already seen above. So much for our heavy and bulky loads…. However, a stack of small boxes can be equally stressful for your warehouse workers because, as the saying goes, ‘little bits make a big whole’. To ensure ergonomic order picking and storage of small goods, it is best to opt for trolleys or shelf trolleys. The right choice often depends on the weight and type of load to be moved. You can read more about this in this article on rolling stock.

-

A trolley with step glides is ideal for overcoming steps.

-

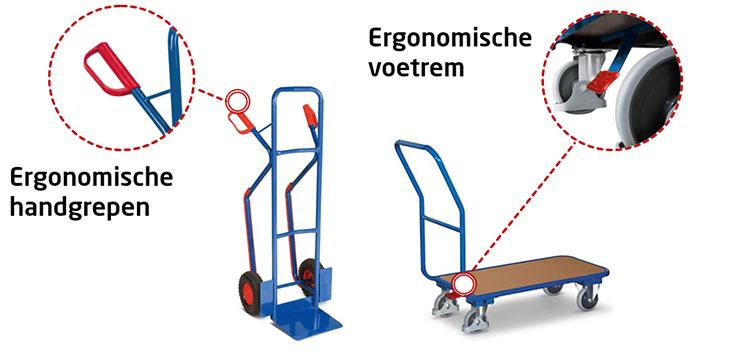

Choose a trolley with an ergonomic handle. This provides a better grip.

-

Finally, we should not forget the platform trolley with central foot brake . The foot brake allows you to easily block the wheels without having to bend down (= less back strain). Even for those wearing robust warehouse shoes, this foot brake is still easy to operate.

► 5. Take your work off your hands with film wrappers

Wrapping pallets is an important stage in the order process. It poses a challenge to your packer every time, as it involves complex operations and involves moving heavy loads.

This type of work puts the shoulders under the most pressure. With a film wrapper, however, you eliminate many risks. This machine does almost all the work for you – and does it faster and more accurately than a human could. Download RAJA’ s e-book and find out which film wrapper is best suited to your company’s productivity.

By now, it is estimated that almost 80% of all companies in the logistics sector already use a stretch film wrapper. Partly for reasons of efficiency and ergonomics.

]

]

► 6. Ease standing work with an anti-fatigue mat

Your warehousemen and packers spend much of the day standing up, don’t they? Unsurprisingly, prolonged upright work encourages complaints related to the back, knees and ankles.

With an anti-fatigue mat, you can easily ease their workload. With its unique ribbed surface, this type of mat ensures that your packer is constantly moving. Only this way will he remain stable. In monotonous work, these small movements make muscle and joint pains less likely to arise.

► 7. Voice picking: combine productivity with technology

In voice picking, your order pickers are provided with a headset. The programme tells them which rack to move to, taking into account the most optimal route.

A voice picking system is linked to a Warehouse Management System (WMS for short). The purpose of the software is to optimise movements in a warehouse and make picking much smoother. Thanks to voice picking, your warehouse workers keep their hands free, significantly reducing the strain on the muscles and joints in their upper bodies. The risk of errors is also reduced, which brings us to the end result: higher productivity.