PLA stands for polylactic acid or polylactide. It is a type of bioplastic that is increasingly used to make packaging materials and canteen supplies (cutlery, cups, etc.). It is growing in popularity due to its image as a plant-based alternative to conventional plastic. We go over the advantages of this raw material below and look at the most commonly used applications.

1. What is PLA?

PLA stands for polylactic acid, referred to as PolyLactic Acidin English. In chemistry, it is called a ‘thermoplastic’. This indicates a plastic that softens when heated. A big difference compared to traditional plastics is the raw material. PLA is not made from petroleum but from a renewable, vegetable source. Its base consists of lactic acid, which is obtained from agricultural crops such as maize.

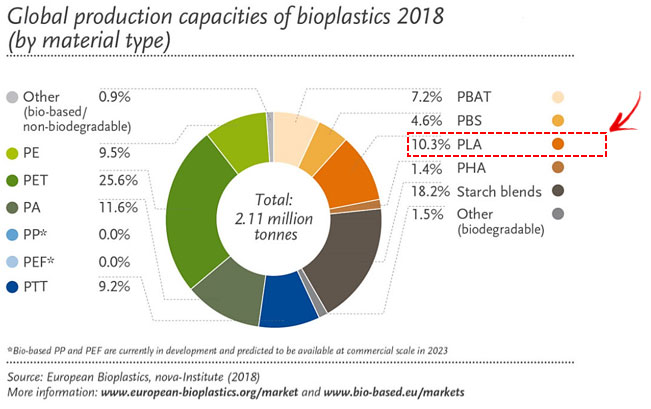

The chart below shows us that PLA accounted for just over 10% of all bioplastics produced in 2018. By 2023, that figure could rise to 16.2%.1 This will make it one of the most produced forms of bioplastic.

2. The main advantages of PLA

► Compostable

Many PLA products are degradable under industrial composting conditions (from +58 °C). In doing so, much higher composting temperatures are reached than in the compost heap in your garden. It is therefore important that PLA is still properly sorted and recycled. Otherwise, it will also stay in the environment longer than it should. Pending clearer regulations, it is best to throw these bioplastics in the residual waste for the time being.

To be sure that the piece of bioplastic you hold in your hands is compostable, look for the Seedling or TUV Austria logo. If this logo is on the packaging, it can be industrially composted.

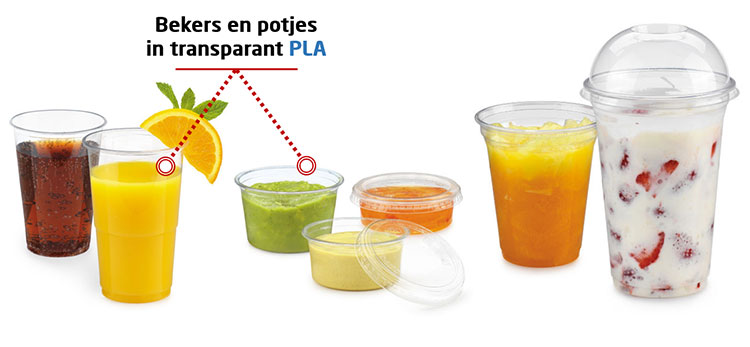

► Transparent

A second advantage of PLA lies in its transparency. Your packaged products remain perfectly visible. This is often an absolute must when packaging food. So your customer immediately knows that your vegetables, fruit or desserts look great. By the way, you can add a dye to PLA to make it no longer transparent – should the need arise.

► Flexible

The third big advantage of PLA? That is its flexibility! It can therefore be used for all kinds of products and packaging materials. The possibilities are virtually endless. In addition, PLA can also be made harder by adding lime, for example. This is CPLA, where the C stands for Crystallized. This ‘crystallised’ PLA is opaque and has a higher heat resistance.

- Firstly, it saves on fossil raw materials - a resource we do not have an infinite supply of. Instead, we use a renewable biomass (e.g. maize or sugar cane).

- The second advantage: during the growth of these plants, CO2 is filtered out of the air. Bioplastics thus have the unique ability to neutralise CO2.

3. Popular applications

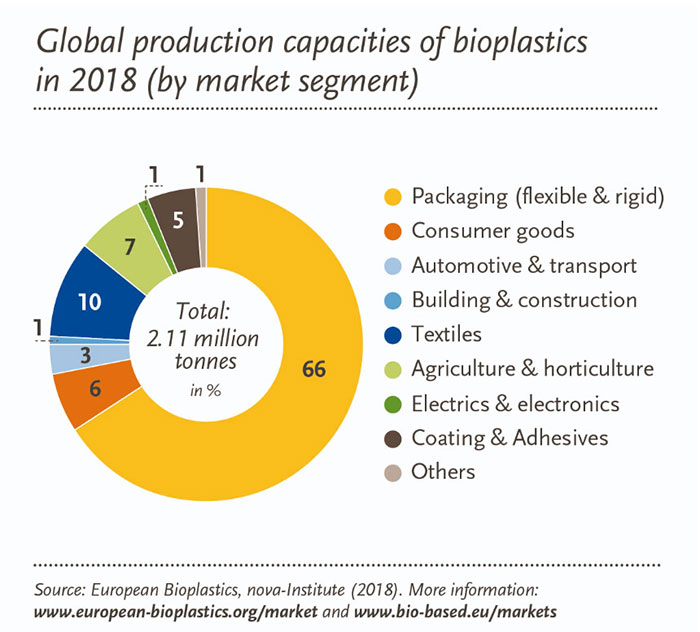

As the figure below makes clear, bioplastics are particularly popular in the packaging industry (accounting for 66%).1 PLA, for example, lends itself very well to food presentation and packaging: think trays for fruit or vegetables, drinking cups, jars for sauces, etc.

Those who want to equip their canteen, restaurant or catering company with sustainable cutlery and cups can opt for RAJA’s range below. For cold drinks or food, it is best to use standard PLA. For hot drinks or food, we recommend using the reinforced variant: CPLA.

Bioplastics come in a wide variety of forms. Here at RAJA, for example, we use biobased film to protect our shipped catalogues. This film is made from sugarcane. It is 100% recyclable, along with traditional LDPE plastics. However, it is more sustainable and renewable because of its origin from plant waste streams.

Bioplastics come in a wide variety of forms. Here at RAJA, for example, we use biobased film to protect our shipped catalogues. This film is made from sugarcane. It is 100% recyclable, along with traditional LDPE plastics. However, it is more sustainable and renewable because of its origin from plant waste streams. Source:

1 www.european-bioplastics.org