You’ve experienced it yourself before: you open a car door and feel a small electric shock. Then there was actually an electrostatic discharge or ESD. Such a discharge can also build up in packaging. If you regularly ship electronics, it is important to consider the consequences. Therefore, opt for appropriate packaging and sleep peacefully on two ears.

1. What exactly is an ESD?

The abbreviation ESD stands for Electro Static Discharge, or electrostatic discharge. Static electricity is created by friction, for example between pieces of plastic (which we find in many clothes). If static electricity cannot flow away to earth, this energy can increase further with every movement. For example, if you wear a garment with a high electrostatic charge, your hair will stand up.

Weather conditions play a big role in the build-up of an ESD. Cold, dry air is the best basis for static electricity. We therefore suffer from it more often in winter than in summer.

2. What are the consequences of an electrostatic discharge?

The effects of static electricity can be annoying:

- plastic bags stick together and you can hardly open them;

- you get a shock when grasping a door handle or car door;

- thin plastic clothing (polyester) can stick to your body.

The sparks created by an electrostatic discharge are not harmful to humans. The situation is different for electronics. Electronics that have suffered an ESD actually break down much faster or will work worse. The consequences of the ESD may only become apparent years later. So prevention is better than cure…

]3. How do you recognise an ESD package?

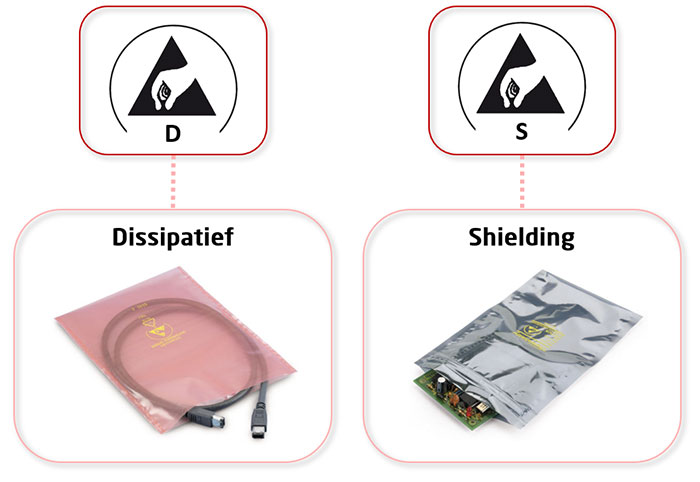

An ESD package can be designated by one of two symbols (see below). The D under the triangular logo stands for Dissipative. The S refers to Shielding. What exactly the two mean we will explain further below. For now, it is good to know that dissipative packaging is often pink. With shielding, the packaging along the outside often has a metallic colour.

4. What types of ESD packaging exist?

Under what forms can ESD packaging occur? Most respond to the fact that you need to be able to pack electronics with it. Computer components in particular are sensitive to electrostatic discharge and thus require extra protection. You have a choice of:

- [1] Bags (with pressure or adhesive closure) or bubble wrap

- [2] Foam sheets (in polyurethane or polyethylene)

- [3] Stretch film (for pallet wrapping).

5. What is the difference between dissipative and shielding?

ESD packaging comes in two versions. The differences between the two are subtle, but have a big impact on how you want to protect your products.

► Dissipative packaging (i.e. the pink variant) is ideal for objects that are frequently held by people. This is because our bodies are high conductors of energy and can easily create a static spark. Dissipative packaging allows an electrostatic charge to flow more slowly and in a more controlled manner from one material to another. So with this type of packaging, an ESD is not avoided but the energy released is much lower. As a result, damage to electronics can be avoided.

► The second type is shielding packaging. These packages consist of multiple anti-static layers (or ‘shields’) that create a Faraday cage around your product. They therefore prevent the build-up of static electricity and best protect against an ESD. To be effective, shielding packaging should always be fully sealed; for example, by sealing it tightly or using a press-fit closure.

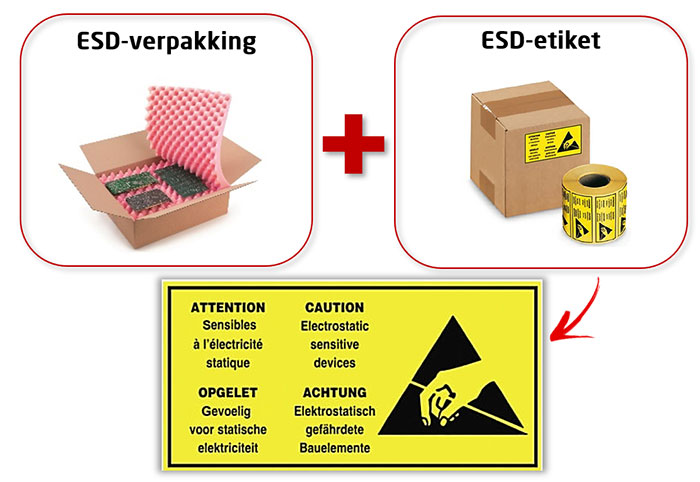

]6. How do you ship ESD packaging?

Now that we know what an ESD package is, and what it looks like, finally, we’ll give you a quick guide on how to ship these packages. Best to stick the label below on the outside of your packaging. This way, it is always clear to the sender and recipient that your package contains sensitive products. A well-warned man/woman is worth two.