Smart cities, smart homes, smart TVs, smart watches… The range gets longer and longer every year. Even packaging can be ‘smart’ these days. They offer many more possibilities for the user and for protecting your products. Time to stop at two types of such smart packaging: intelligent and active. The difference between the two may not mean anything to you now but we will soon change that.

1. The two faces of smart packaging

Like everything ‘smart’, smart packaging makes our lives easier. They are generally divided into two categories.

► First, there is smart packaging. This is designed to inform the user. It is often a sensor or indicator added to a package so that information can be collected. For example, they indicate when a temperature was exceeded, when a pack tipped over or when a best-before date was reached. Intelligent sensors can be attached to packaging either inside or outside.

► First, there is smart packaging. This is designed to inform the user. It is often a sensor or indicator added to a package so that information can be collected. For example, they indicate when a temperature was exceeded, when a pack tipped over or when a best-before date was reached. Intelligent sensors can be attached to packaging either inside or outside.

► Secondly, we also have active packaging. This kind will protect your products. In doing so, it ‘activates’ itself to counteract changes in the packaging. The aim is to keep your product in good condition for longer. Think of desiccant: if moisture penetrates your packaging, the desiccant will neutralise it and thus protect your product. The active element can be added to the packaging as an insert (like the desiccant) or fully integrated into it (like ESD packaging).

► Secondly, we also have active packaging. This kind will protect your products. In doing so, it ‘activates’ itself to counteract changes in the packaging. The aim is to keep your product in good condition for longer. Think of desiccant: if moisture penetrates your packaging, the desiccant will neutralise it and thus protect your product. The active element can be added to the packaging as an insert (like the desiccant) or fully integrated into it (like ESD packaging).

2. Examples of ‘smart’ packaging

Intelligent packaging is able to track, measure and report changes to your products – without affecting your product. Good to know: the indicators below don’t just help you gather information. They also create greater awareness among those handling your products. The indicators often stick to the outside of a package, making it clear to everyone that it should be handled more carefully. Thanks to the indicators, you also know perfectly where in the logistics chain an error occurred.

Indicator for cold |

Heat indicator |

| – The window turns purple if the too-low temperature persists for more than 30 min. – Operates continuously (no activation required). – Make it stand out with this label. |

– 3 windows turn red in succession when exposed to too high temperatures. – Activation: pull the protective tab. – Make it stand out with this label. |

Shock indicator ShockWatch® |

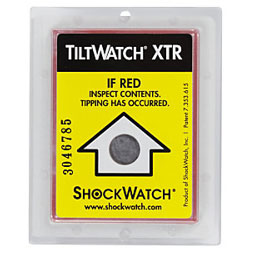

Tilt indicator TiltWatch® |

| – Colours when your package was subjected to a certain gravitational force (shock). – Ideal for products that are very fragile. – Make it stand out with this label. |

–Discolours when package tilts more than 83°. – Ideal for products with liquids such as air conditioners or batteries (with battery acid). – Make it stand out with this label. |

3. Examples of ‘active’ packaging

Active packaging takes action itself to protect your products. As soon as a harmful substance is detected (water, moisture, oxygen, etc.), the active packaging does its job. Here are a few examples:

Desiccant |

ESD packaging |

| –Protects against damage caused by moisture or corrosion – Often used with food or clothing. – See all options of drying bags with clay or silica gel here. |

– Protects against electrostatic discharge. – Suitable for packaging electronics. – View all options of anti-static ESD packaging here. |

4. Two sectors that cannot do without

Food sector

Time and temperature are two factors that have a disastrous impact on what we eat and drink. Smart packaging is indispensable in the food sector. For example, they tell us whether the imposed temperature was respected (and for how long). There are also indicators that respond to humidity, best-before date or traceability (to know where your food comes from). One of the most innovative packaging techniques is MAP (Modified Atmosphere Packaging). This involves pulling air out of the inside of the packaging. People then replace it with a gas mixture that better protects the food from deterioration. People use it for keeping vegetables crisp, among other things.

Pharmaceutical sector

Smart packaging ensures proper preservation of medicines and promotes proper patient compliance. Besides ‘simple’ smart packaging such as temperature indicators and drying bags, new technologies are increasingly being used. NFC and Bluetooth, for example, make it easier for the packaging to ‘communicate’ with the patient (via his smartphone). German company Faller Packaging designed an interactive packaging called “Smart Packaging“. The pillbox reminds patients when to take their medicine and exactly how to take it.

The smart packaging market is definitely one to keep an eye on further. For the period 2017-2023, it is projected to grow at around 5% annually (Market Research Future). No doubt, a lot of new applications and technologies will still penetrate our everyday packaging. Curious to see what the future holds!