Have you ever come across high shipping costs, despite the low weight of your parcel? Did you know that it is not enough to consider the actual weight of your shipment to know the cost? Have you ever heard of volumetric weight?

In order to determine the rate they charge their customers, shipping companies pay attention not only to the actual weight of the goods, but also to the volumetric weight, which takes into account the bulk, which is why it is essential to have the right size packaging.

The wrong packaging for your products could have a higher volumetric weight and therefore affect the cost of your shipments, causing them to increase considerably!

In this article, we will explain what volumetric weight is, how it is calculated and what to take into account to keep your shipping costs under control!

What is volumetric weight?

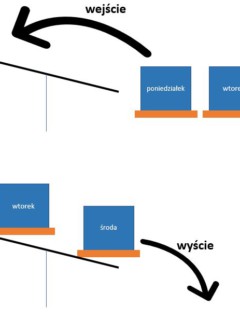

Volumetric weight is the mathematical calculation of the weight and space occupied by a commodity in the medium used for its shipment, taking all its dimensions into account. Couriers usually use volumetric weight instead of actual weight because planes, trucks and containers carrying goods fill up before they reach their maximum allowed weight, and consequently dimensions alone are not enough to calculate the size of a package.

Transport companies use this measure as a guide to determine the price of the shipment when dealing with large parcels that proportionally weigh much less than their volume.

When it comes to assessing a parcel to be shipped, both its actual weight and its volumetric weight are calculated, the shipping company will then decide on the rate to be charged based on the higher of the two. Thus, the cost of sending light but bulky goods can be high.

How to calculate the volumetric weight of a box?

Several formulas can be used to calculate the volumetric weight of a box.

Each transport company uses its own method. It is therefore essential to consult the rules followed by your suppliers to ensure that you choose the best option for your business.

Here is the formula for calculating the volumetric weight of a box

There are several ways to calculate the volumetric weight of a parcel, here is the general formula.

The first step is to measure the three dimensions of the parcel to be shipped: length, width and height in centimetres.

Each courier has its own volumetric weight coefficient, which normally ranges from 200 to 300, depending on whether 1 cubic metre is considered equal to between 200 kg and 300 kg; this figure must be provided by the courier and cannot be calculated without it.

Having this data, one can extrapolate the coefficient to be used to calculate the volumetric weight of an individual parcel, using this formula:

- 1 cubic metre = 100 cm x 100 cm = 1,000,000 cubic cm

- 1,000,000 cubic cm / 200, you get a coefficient of 5,000 (in the case of 200 kg).

We can now calculate the volume of the parcel we want to ship, for example:

- 50 cm length x 30 cm width x 20 cm height – 50x30x20=30,000 cubic cm

- 30,000 cubic cm / 5,000 (coefficient previously obtained) = 6 Kg which is the volumetric weight of the parcel.

Thus, if the parcel in the example actually weighed 4 kg, having a volumetric weight of 6 kg (calculated on the basis of the volume and the coefficient given by the carrier), the greater of the two, i.e. 6 kg, must be taken into account for the purpose of calculating the shipping cost.

The calculation method is always the same, but each carrier provides different instructions and simulation tools:

The Italian Post Office only uses the actual weight as a parameter and has higher average costs than couriers.

Whereas for an air shipment, according to the IATA (International Air Transport Association) international convention, the cost is assessed, again, based on volumetric weight and using the same formula as above. The only difference is in the coefficient, which is higher at 6,000.

How does the actual weight of the packaged product affect the cost of shipping?

When you choose boxes that are too large to pack very light objects, the impact of volumetric weight on the cost of shipping is clear: you are not only paying for the precise space in which to place the products you are sending, but also for the extra space that accompanies them inside the box.

The decision on how to package the product to be shipped is not trivial!

It is, therefore, very important to choose the correct type of box and filling to avoid high shipping costs as well.

How can you control volumetric weight to save money on your shipments?

Excess packaging contributes to damaging your brand image and increasing the cost of your shipments through increased volumetric weight. To avoid this, the solution is to optimise your company’s packaging: again, ‘less is more’!

Before calculating the volumetric weight, therefore, it is important to choose the correct packaging, not to overload the package and at the same time ensure the protection of the goods.

Lightening the packaging and filling, while maintaining the quality of the box and protection, are choices that favour a lower volumetric weight and consequently a lower shipping cost.

Rajapack is the best packaging supplier to help you identify the best option for shipping your products, with a twofold objective:

- that they travel properly protected, so that they arrive at their destination intact

- and that they take up as little space as possible on the plane, truck or train, to reduce the cost of shipping as well as the environmental impact.

To keep transport costs low, it is therefore essential to adapt the packaging format to the goods it contains and to avoid unnecessary empty spaces. Rather than using standard boxes, the empty spaces of which have been filled with bulky filler material, it is better to use cardboard boxes that can be adapted to the height of the contents, or, when possible, opt for a padded envelope instead of a box.

Search on our website or in our catalogue:

- a wide choice of boxes, 700 formats always in stock in different sizes: you can choose the type and size best suited to your needs.

- Boxes adaptable in height, from 3 to 11 heights, and with instant assembly, adapt to the contents and allow you to use less filling material to fill gaps and save warehouse space by reducing the number of boxes in stock.

- A wide variety of filling materials for packaging, with lightweight, quality options that protect your goods without excessively increasing your shipping volume.

Optimise your parcel preparation with Rajapack and volumetric weight will no longer be a problem!