Do you still remember the classic game Tetris? I was reminded of it when I recently had the opportunity to visit one of our customers in his logistics centre at the very moment when he was loading boxes onto pallets. Although the bottom row doesn’t disappear when the space is filled correctly, as in Tetris (thankfully!), only an even distribution of the load leads to victory.

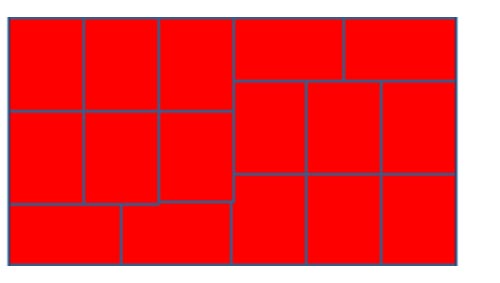

If you are stacking rectangular boxes, try to create compact, interlocking stacks. This not only increases the number of cartons on the pallet, but also stabilizes the entire pallet load! The so-called “ideal case” in Tetris is called “modular packaging” in the logistics dictionary . Modular pallet loading without gaps is possible if you work with box dimensions that can be derived from a 400 x 600 mm ratio.

In fact, pallet dimensions of 800 x 1200 mm and 1000 x 1200 mm, which are very suitable for palletising, are internationally standardised. This allows you to optimise the layout and total number of boxes on the pallet.

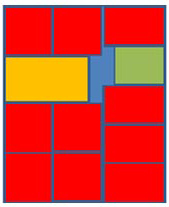

If you want to stack boxes of different sizes, we recommend following these rules for efficient and safe palletizing:

– Place heavy boxes at the bottom and light boxes at the top of the pallet.

– Stack the smaller boxes first on the pallet and end the stack with the largest packages – this reduces the risk of instability of individual small cartons.

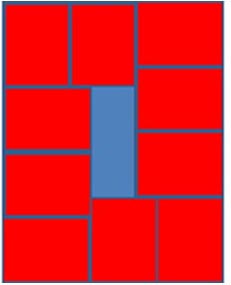

– Always direct any gaps between boxes to the inside of the pallet – keep the outer surfaces solid and perpendicular. This not only makes the load more durable, but also makes it easier to secure with strapping or fixing films.

Everything you need for palletising, such as strapping tapes, strapping kits, tensioning foils and also protective edges to strengthen boxes or increase the compactness of pallets can be found at Rajapack – as well as pallets and boxes!

Author Ludmila, External Service Department