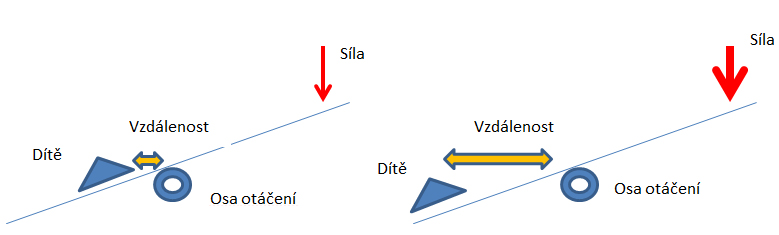

The fact that the rudl makes lifting and transporting cargo easier is widely known. But how does it work? This ingenious invention uses two revolutionary physical breakthroughs: wheels and levers. Archimedes’ famous “Give me a point and I will move the Earth” 250 BC was already based on the principle of leverage. The principle is quite simple: the power required to lift is the product of force and distance. The force needed to lift a load depends on the distance of the load from the axis of rotation. To simplify: the closer the child sits on the swing to the end of the swing, the more force you have to exert to bring the swing to a horizontal position. The closer they sit to the centre of the swing, the easier it is to lift them.

With a ruddle, the centre of gravity is in the centre of the wheel. The load surface (e.g. shovel, plate) on which the weight is loaded is close to the weight for optimum use of force. Depending on the material properties of the transport trolley (e.g. aluminium, steel tube or stainless steel), this allows loads of large weights to be lifted and transported. In warehousing and logistics, this makes the rudl an indispensable tool. It saves strength, back and joints, as the load does not have to be lifted from the ground – a considerable benefit for work safety. It is also possible to lift more than one box with the stacking rudl, for example a whole stack!

As an aside: the first ruddles existed in antiquity. Back then, the wheel was made of cast steel and the carriage was made of wood. It was then used very often for transporting sacks of flour, which is why it is often called a sack rudle in other languages, Sackkarre in German, and Sackrodel in Austrian.