According to the results of RAJA ‘s e-commerce survey, one of the top priorities in the e-commerce sector, along with ecology and security, is optimising transport costs. How to achieve this in reality? Shipping costs can be influenced in particular by choosing the right packaging materials and calculating the right shipping price.

A survey of e-commerce retailers conducted by RAJA showed that 20% of them put reducing shipping costs at the top of their priorities. “Shipping is expensive and as a result reduces the profitability of e-commerce stores. Merchants are therefore looking for solutions to reduce shipping costs while maintaining a high level of delivery quality, which can often be a difficult dilemma,” comments Gabriela Fabiánová, CEO of RAJA.

Reducing costs should not be at the expense of packaging quality

Reducing the costs associated with packaging and transporting goods should certainly not be at the expense of the quality of the materials used. In this case, the risk of damage to the goods could increase, which is associated with an additional set of costs and loss of customers. Packaging can be efficiently optimised in other ways than taking the risk of using cheaper packaging material. Factors influencing the cost of shipping include:

● Height and weight of the product

● packaging design

● packaging material

● Bulk weight, or the space the product takes up during transport.

Another decisive factor is the so-called transport density of packages, which can be understood as weight per cubic metre. “Transporting 20 kilograms of feathers can be more expensive than transporting 20 kilograms of iron,” explains Gabriela Fabiánová. “Appropriately chosen packaging to fit on a pallet or in a truck can reduce costs by up to 10%,” she adds.

Aleš Juřina of the tea lovers’ association also confirms this. “The Czech Post has recently started charging freight according to the length of the longest side. Now we have the advantage of packaging from RAJA, where we can choose the optimum size of packaging. I think we can save around 10-15% of the shipping costs thanks to the appropriate packaging,” Juřina describes the situation.

How to find out the optimal bulk weight?

One of the biggest current trends in logistics is to reduce the packaging density of shipments, and companies that do not pack their products efficiently are literally paying the price for this – the so-called bulk weight is now used to determine shipping prices by most international shipping companies such as UPS, TNT, DPD or Der Kurier. PPL also counts on the volumetric weight for international shipments, and Czech Post uses it for oversized shipments over 850 kg.

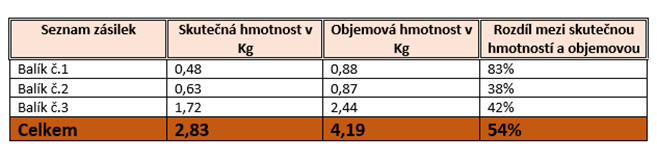

Bulk weight is calculated according to the dimensions of the package: width x length x height / 5000. The result gives the bulk weight, which is compared with the real weight of the package. Higher carriers charge the latter. The optimum bulk weight is therefore the weight that is closest to the real weight.

With a simple calculation, you can see how much you can save by optimizing the package dimensions.

So instead of a one-size-fits-all packaging strategy, it pays to try individual packaging tailored to the products being transported. If the product range is really varied, the ideal solution for online retailers is to use height-adjustable cartons (telescopic cartons) that can easily adapt to the size of the contents.

“By optimising packaging, it is possible to save money in the long run on all aspects. But studies suggest that many packages contain up to 40% empty space in the boxes that needs to be filled with something. Thus, poorly chosen box sizes not only cost money, but also put a strain on the environment – taking up more space in transport vehicles and consuming too much material unnecessarily. Therefore, it is worth taking the bulk weight into account even if the transport company does not charge anything for larger dimensions,” adds Gabriela Fabianová.

1. 200 respondents took part in the survey, of which 150 were only in the e-commerce sector.

Save smart on packaging

According to RAJA, material costs represent on average 60% to 80% of the total cost of packaging. The cost of materials depends on various parameters such as type, quality or the manufacturer of the packaging itself. Different designs of the same volume sometimes need different amounts of material also play a role. With some types of materials, “swapping” the height and width of the packaging can save 20% of the material used.