When you’re new to corrugated board, it’s useful to know the difference between single, double and triple corrugated. A simple answer might be the thickness and strength of the board. For a more detailed answer, click here

Single, double and triple corrugated

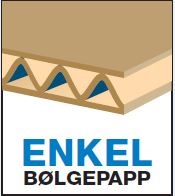

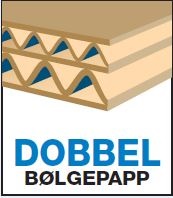

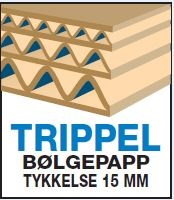

the thickness and strength of a corrugated sheet depends on the type of flute it is made of, and can vary between 2 and 15 mm. It is the flute and its thickness that classifies the sheets, and it is divided into: single, double or triple corrugated

- Mini-corrugated (micro-corrugated): this is the thinnest corrugated and the one most often used for the simple sheets, sheets that do not have to carry any significant weight. This is about 2 mm thick

- Single flute (single corrugated): Single corrugated is used for more and more universal baits. It consists of single flute, has a thickness of about 5 mm* and recommended weight up to 20 kg.

- Double flute (double corrugated board): Double corrugated board is a resistant flute, with a thickness of approximately 7mm* and a recommended weight of up to 70 kg.

- Triple flute (triple corrugated): This is the most resistant cardboard sheet you get. It has three flute, a thickness of about 15mm* and recommended weight up to 500 kg.

(*The measurements are based on standard RAJABOX corrugated cardboard: mini, single, double and triple. The composition from other manufacturers may have different thicknesses.) Here you can see the difference in pictures:

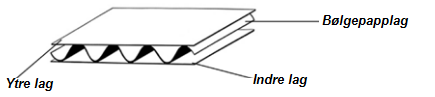

Cardboard structure

det er viktig å huske at grunnmuren i de fleste pappesker er bølgepappen (med eller uten flute). Bølgepapp består av et ytre lag, et bølgepapplag og et indre lag, totalt tre komponenter. Hvis pappen har to eller flere flute (dobbel eller trippel bølgepapp) er det minst to lag av innvendig papir. Det ytre og indre laget er underlagt forskjellige krav: Det ytre laget er produsert i kraftpapir og skal kunne tåle fukt, temperatursvingninger, samt lager- og frakthåndtering. Ytterlaget skal også sørge for styrke til stabling og ha en optimal overflate å trykke logo på og til pakketape. Det indre laget består av et ark som en limt på undersiden av bølgepappen.

Pappesker er kundenes foretrukne emballasje, langt foran plastikk, tre og metall. Her har vi listet opp alle fordelene ved pappesker

- It’s easy to work with

- The material is light in weight

- High resistance

- Shock absorbing effect gives good protection

- Good air circulation

- Protects against moisture

- Can be tailored to almost any need

- Environmentally friendly and reusable.

Which cardboard spoon for your product?

when selecting the right paperboard tray and corrugated thickness for your product, it is important to focus on your product and take all elements into consideration. In other words, get to know your product and protect it so that the customer receives a flawless product. One tip is to create an idea map of your product. Here are elements that should be considered

- Is the product shielded?

- Is the product heavy?

- Will the box be used for storage or shipping?

- Do you want the box to be stackable?

when selecting a cardboard box, be aware that the products’ differences, damage and use require different considerations. If you are sending products to other parts of the world, it is advisable to take these elements into account during transport

- Will it be shipped by road, sea or air?

- Will it be loaded where it is stacked with other boxes?

- Will it be stored for days, weeks or months?

- Does it have to be pallet-adapted?

- Is there high humidity or pressure?

- How many transport links does the package have to pass through?

take all the elements you can analyze into consideration. The more, the better, so that you are sure that the packages arrive intact. At Rajapack we always have over 600 cardboard boxes in stock.