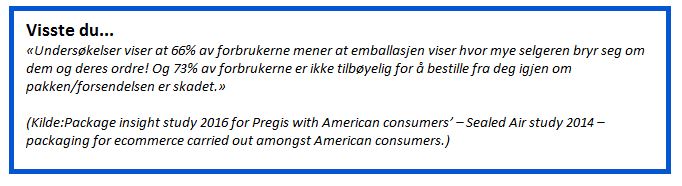

Good customer care is important, and one way to do that is to make the best impression on the customer when they receive the package from you. This is as much about paper quality as it is about the right filling material. Always make sure that your shipments are properly protected, and that the contents get exposure that matches your brand. The quality of shipments being delivered today has become like a showcase, and in many ways constitutes the company’s “relationship” with the customer. Sending sloppy packages can give the impression that you are a sloppy company. If, on the other hand, you have packaged properly, then there is a good chance that loyalty levels will increase. In other words: you focus on the customer experience.

Filling material

we who have worked for many years in the packaging industry are aware that not all transport factors we can influence as shippers, such as rough roads and careless drivers. What we can do is minimise the danger and show that we have done our best to ensure that the product reaches the customer in good condition. At RAJA we have many different types of filling material, and each has its own characteristics. Filling material today is not just filling material, because package filling can have many other functions than just protecting. It can also help present a product aesthetically and/or optimise the packaging process or shipping costs. We have described three different but protective types of filling material

Paper fill – aesthetic and practical

it is not always possible to adapt the packaging exactly to the product. Examples could be if it is a small package or if the product is in several parts. Here, loose fill material is a good solution, and paper fill is practical for filling the void and keeping small parts separate during transport. Paper fill is a traction folded strip produced from 100% organic paper. In addition to being protective, it is also decorative and available in several colours. Therefore, paper fill also works well as a gift packaging.

Airputer – soft, light and dust absorbing

airpuffs are the filling material most often preferred by customers. They work well for filling rum in larger product sizes and absorb dust both externally and internally. The advantages of airpuffs include that they do not spoil when the package is opened and that they are extremely light in weight. Airpuffs consist of 99% air and 1% plastic, which gives lower shipping costs and leaves only 1% for disposal. If you also invest in an airpuff machine, it is possible to inflate and make the amount of airpuffs you need yourself, and there are different variants of airpuff machines.

Bubble wrap – wraps, protects and absorbs shock

en god gammel klassiker som også er populær hos kundene er bobleplasten. Forskjellen mellom luftputer og bobleplast er at de skal brukes på forskjellige måter. Du må bruke mer bobleplast enn luftputer for å fylle opp tomrom, men bobleplasten kan pakke inn, skille og beskytte. Bobleplasten kan også fåes i mange forskjellige varianter, som bobleplast på dispenserboks, bobleposer, antistatisk bobleplast, bobleplast med store bobler osv.

En god venn med bobleplasten er skumfolien, som også pakker inn og beskytter. Skumfolien er blant annet ideell til innpakning av glass og polerte overflateprodukter som har en skjør overflate.

Ønsker du enda mer inspirasjon til å velge fyllmateriale, så besøk vår nettbutikk eller kontakt våre spesialister på post@rajapack.no / 22 51 40 00.